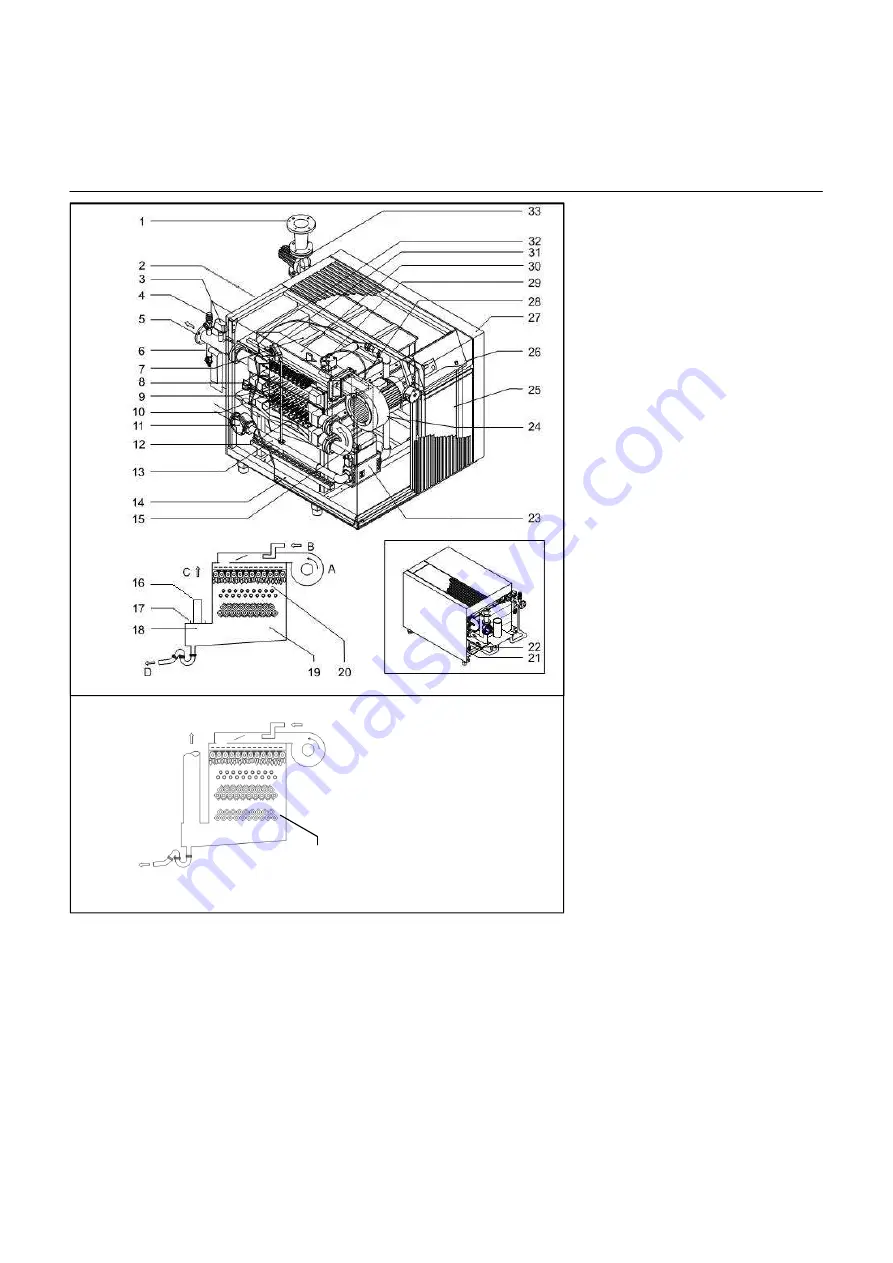

Construction

Layout of boiler

Operating principle

3

Layout of boiler

The R3400/R3500/R3600 boiler con-

sists of the following main components:

1

Return water connection

2

Flue gas connection

3

Water flow switch

4

Safety valve

5

Flow water connection

6

Filling/draining valve

7

Top plate

8

Plenum

9

Burner

10 1st Heat exchanger

11 Gas filter

12 2nd Heat exchanger

13 Gastrain

14 Frame

15 180° Bend

16 Compensator

17 Flue gas connection

18 Condensate receptacle

19 Flue gas receptacle

20 Combustion chamber

21 Entry electrical connections

22 Syphon

23 Main gas valve

24 Fan

25 Electrical box

26 Control panel

27 Casing

28 Air inlet damper

29 Butterfly valve

30 Main mixing channel

31 Pilot gas valve

32 Pilot mixing channel

33 Boiler pump

34 3rd Heat exchanger (only R3600)

A Air

B Gas

C Flue gasses

D Condensate

Operating principle

The R3400/R3500/R3600 is a fully

modulating boiler. The control unit of

the boiler adapts the modulation ratio

automatically to the heat demand re-

quested by the system. This is done by

controlling the speed of the fan. As a

result, the Whirlwind mixing system will

adapt the gas ratio to the chosen fan

speed, in order to maintain the best

possible combustion figures and there-

with the best efficiency. The flue gases

created by the combustion are trans-

ported downwards through

The KM628 control unit can control the

boiler operation based on:

•

fixed temperature (stand alone opera-

tion);

•

weather compensated operation (with

optional controller);

•

with 0-10V external influence

(temperature or capacity) from a

building management system.

the boiler and leave at the back side

into the chimney connection.

The return water from the system en-

ters the boiler in the lower section,

where is the lowest flue gas tempera-

ture in the boiler. In this section con-

densation takes place. The water is

being transported upwards through the

boiler, in order to leave the boiler at the

top (burner) section. The cross flow

working principle (water up, flue gas

down) ensures the most efficient com-

bustion results.

34