19

05/2005 - Art. Nr. 13 018 071A

Overview

Contents

Page

Overview

Contents. . . . . . . . . . . . . . . . . . . . . . 19

Important notes . . . . . . . . . . . . . . . . . . 19

Technical data, power graphs

. . . . . . . . . . 20

Selection of gas valve assembly . . . . . . . . . 21

Dimensions, Burner description

. . . . . . . . . 22

Function

Compact valve assembly . . . . . . . . . . . . . 23

Operating function, safety function . . . . . . . . 24

Control unit . . . . . . . . . . . . . . . . . . . . 25

Options of connection

. . . . . . . . . . . . . . 26

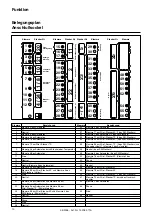

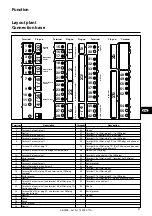

Layout plant, connection base . . . . . . . . . . 27

Installation

Burner assembly . . . . . . . . . . . . . . . . . 28

Gas supply, electrical supply . . . . . . . . . . . 29

Pre-startup check . . . . . . . . . . . . . . . . . 29

Checking / Setting

. . . . . . . . . . . . . . . . 30

Burner head for natural gas / Propane gas . . . . 30

Startup

Burner adjustment data . . . . . . . . . . . . . . 31

Burner adjustment . . . . . . . . . . . . . . . . 32

Pressure switches adjustment . . . . . . . . . . 33

Servicing

Maintenance . . . . . . . . . . . . . . . . . . . 34

Troubleshooting . . . . . . . . . . . . . . . . . . 35

Declaration of conformity for

forced-draught gas burners

We, CEB,

F-74106 ANNEMASSE Cedex

declare under our sole responsibility

that the products

VECTRON G 03.240 DUO PLUS

VECTRON G 03.300 DUO PLUS

conform to the following standards:

EN 50165

EN 55014

EN 60335

EN 60555-2

EN 60555-3

EN 676

Belgian Royal Order of 2004/01/08

In accordance with the stipulations of

directives

89 / 396 /EEC

gas devices

89 / 336 /EEC

EMC directive

73 / 23 /EEC

low-voltage devices

directive

92 / 42 /EEC

working efficiency

directive

97 / 23 /EEC

pressure equipment

directive

These products bear the CE marking.

Annemasse, France, May 1st 2003

J.HAEP

Description of burner

The burners VECTRON

G 03.240/300 DUO PLUS are 2-stage

progressive/modulating burners in a

monoblock configuration. Within their

corresponding power range, they are

suitable for use with all heat generators

designed to conform to EN303.

For any other use, the agreement of

ELCO must be asked for.

The special design of the burner head,

with internal fume recirculation, permits

highly efficient combustion - while

ensuring minimum emissions of

nitrogen oxide.

Important notes

The design and function of this burner

both conform to EN 676 standards.

All installation, initial-startup and

maintenance work must be carried out

by authorised service engineers, who

should observe all relevant guidelines,

directives and specifications.

The installation of the gas conduits and

valve assemblies should likewise be

carried out in conformity with the

applicable directives and regulations

(e.g. DVGW-TRGI 1986/96 ; TRF 1988 ;

DIN 4756).

All seals and sealing material used

must be DVGW tested and approved.

Check seals and connection points for

possible leaks with a suitable

non-corrosive foam product.

Bleed the gas conduit before using for

the first time. DO NOT bleed via the

furnace. Servicing work on switches,

limiting devices and control units - along

with other safety devices - MUST be

carried out by the supplier of each

individual item, or by its authorised

service engineers. Original parts may

only be replaced by an authorised

service engineer.

Scope of delivery

The burner assembly is supplied in two

separate packages:

·

burner with burner head, flange

gasket and fixing screws, with

operating instructions, flow diagram,

spare parts list, boiler-room

information sheet.

·

Gas-valve assembly.

The following standards should be

observed in order to ensure safe,

environmentally sound and

energy-saving operation:

EN 676

Forced-draught gas burner

EN 60335-2

Safety of electrical devices designed

for domestic use

Gas conduits and valve assemblies

must be installed in accordance with

DVGW-TVR/TRGI (gas).

Place of installation

The burner must not be operated in the

presence of corrosive fumes (e.g.

hairspray, tetrachloroethylene or

carbon tetrachloride), large amounts of

dust, or high levels of air humidity (e.g.

in laundry rooms). Ensure that a

ventilation inlet of the following

characteristics is provided:

DE : up to 50kW: 150cm

2

for each additional kW: + 2,0cm

2

CH : up to 33kW : 200 cm²

for each additional kW: + 6,0cm

2

.

Rules may vary according to local

legislation..

We can accept no warranty liability

whatsoever for loss, damage or

injury caused by any of the

following:

–

Unauthorised use - Incorrect

installation and/or

–

initial startup on the part of the buyer

or any third party, including the fitting

of non-original parts.

Handover and operating instructions

The person engaged to install the firing

system must provide the user with

operation and maintenance instructions

no later than at the moment in which

the unit is handed over for use. These

instructions should be displayed in a

prominent location at the point of

installation of the heating unit, and

should include the address and

telephone number of the nearest

customer service centre.

Advice to the user

Have the system professionally

serviced at least once a year. It is

recommended to enter into a

maintenance contract in order to

ensure trouble-free running.

EN

Summary of Contents for VECTRON G 03.240 DUO PLUS

Page 36: ...05 2005 Art Nr 13 018 071A 36...

Page 38: ...05 2005 Art Nr 13 018 071A 38...

Page 41: ...41 05 2005 Art Nr 13 018 071A...

Page 42: ...05 2005 Art Nr 13 018 071A 42...

Page 49: ......

Page 50: ...05 2005 Art Nr 13 018 071A 50...

Page 51: ...51 05 2005 Art Nr 13 018 071A...