35

05/2005 - Art. Nr. 13 018 071A

Servicing

Troubleshooting

Fault diagnosis and repair

Before carrying out fault diagnosis,

check that the basic requirements for

correct operation are being fulfilled:

1.

Is the system connected to the

power supply?

2.

Is the system connected to the

gas supply?

3.

Is the gas shutoff cock open ?

4.

Are all regulating and safety

devices (boiler thermostat, low

water level detector, end-limit

switches, etc.) correctly adjusted?

If the malfunction persists:

·

Note any blink-codes emitted by the

control unit, and check their meaning

with the following table. It is possible,

using the readout device (available

as an optional accessory), to obtain

further in-depth information on the

system's operating and malfunction

procedures.

DO NOT attempt to repair safety

components. Replace them with

original parts bearing the same order

number.

m

Use ORIGINAL spares only.

Note:

After each intervention:

·

Check combustion performance and

examine the individual conduits for

signs of leaks under real operating

conditions (doors shut, hood fitted,

etc.).

·

Note down the results in the

corresponding report forms.

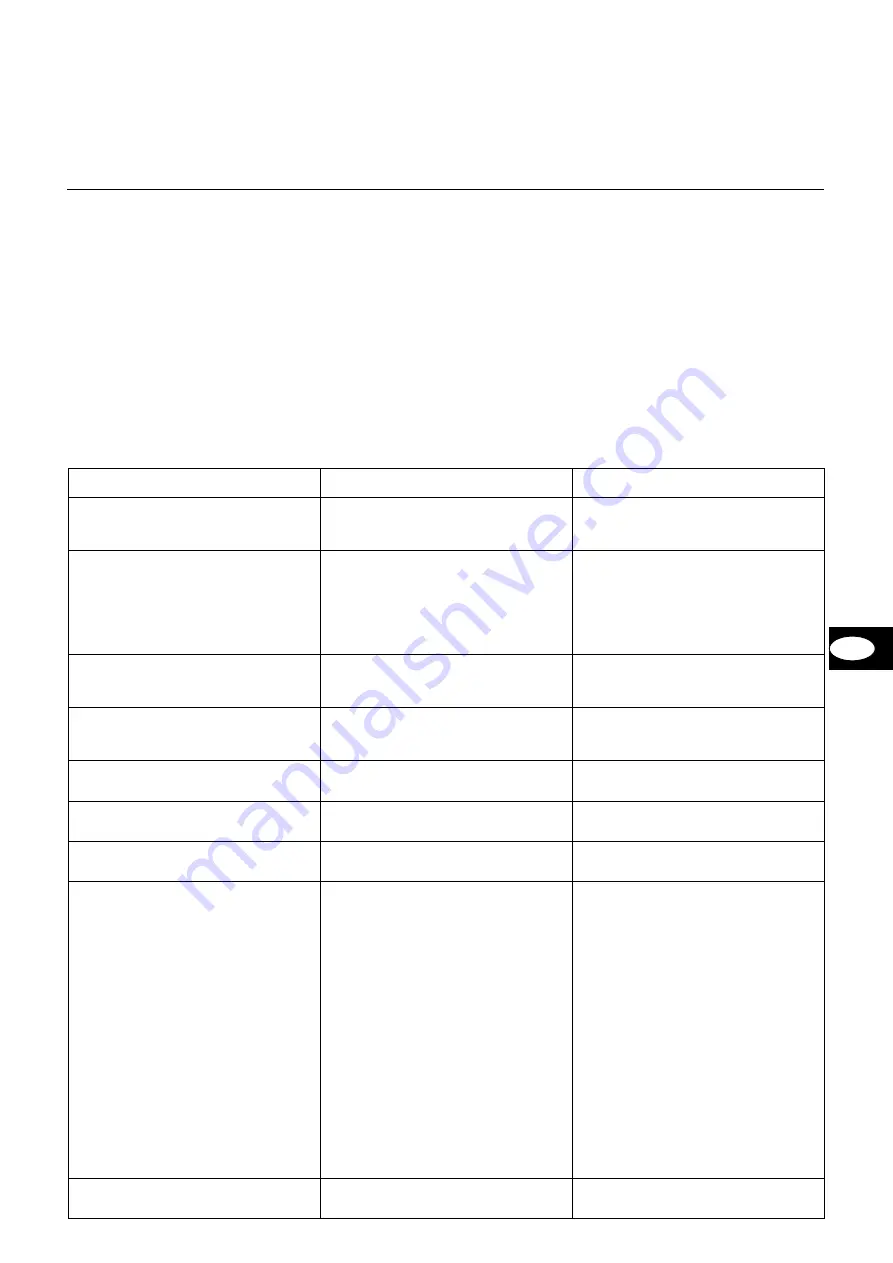

Malfunction

Cause

Remedy

Burner fails to start after thermostat

signal.

No fault indication on control unit.

Brownout or power cut.

Fault in control unit.

Check for cause of reduction or failure of

power supply.

Replace control unit.

Burner fails to start.

Gas pressure normal.

Air-pressure switch in working order.

No request for heat.

Insufficient gas pressure

Gas pressure switch maladjusted or defective.

Air-pressure switch not in home position.

Thermostat defective or maladjusted.

Check gas conduits.

Clean filter.

Check gas pressure switch or replace

compact gas-fired unit.

Readjust or replace air-pressure switch.

Readjust or replace thermostat.

Burner activates briefly at startup,

then shuts down and emits following signal:

x x y y y

-

y y y y y

Control unit has been shut down intentionally. Reset control unit.

Burner fails to start.

y y x x x

Air-pressure switch: not in home position

incorrectly adjusted fused contact

Readjust pressure-switch

.

Replace pressure-switch.

Burner-blower starts up. Burner fails to start.

x x x y y

Air-pressure switch: Contact fails to close.

Examine pressure-switch and check wiring.

Readjust pressure-switch.

Burner shuts down during normal operation.

x x x x y

Air-pressure switch: Contact opens at startup

or during continuous operation.

Readjust or replace pressure-switch.

Burner-blower starts up. Burner fails to start.

x x y y y

Light scatter during pre-ventilation or

pre-ignition.

Replace valve.

Burner starts up, ignition sequence activates,

then stops

x y y y y

No flame present at end of safety period.

Gas throughput rate incorrectly adjusted.

Fault in flame-monitoring circuit.

No ignition arc.

Electrode(s) shorted.

Ignition cable damaged or defective.

Ignition transformer defective.

Control unit.

Solenoid valves fail to open.

Valves jammed.

Regulate gas throughput rate.

Check general state and adjustment settings

of ionisation probe by connecting to earth

(ground).

Check general state and connections of

ionisation circuit (wiring and measuring

bridge).

Clean and adjust ignition electrode(s),

replacing as required.

Connect or replace ignition cable.

Replace transformer.

Replace control unit.

Check wiring between control unit and

external components.

Check coil, replacing as required.

Replace valve.

Burner shuts down during normal operation.

y y y y x

Flame goes out during normal operation.

Check circuit of ionisation probe.

Check control unit, replacing as required.

EN

Summary of Contents for VECTRON G 03.240 DUO PLUS

Page 36: ...05 2005 Art Nr 13 018 071A 36...

Page 38: ...05 2005 Art Nr 13 018 071A 38...

Page 41: ...41 05 2005 Art Nr 13 018 071A...

Page 42: ...05 2005 Art Nr 13 018 071A 42...

Page 49: ......

Page 50: ...05 2005 Art Nr 13 018 071A 50...

Page 51: ...51 05 2005 Art Nr 13 018 071A...