14

09/2005 - Art. Nr. 13 019 526A

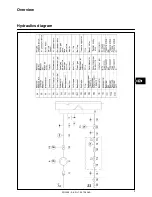

Boiler door preparation

·

Prepare the burner plate/boiler doors

as per the drawing.

·

Stipulate interior diameter Ø 195 mm.

·

Four M10 holes (220-260 mm

diameter circle) are required, as

indicated in the accompanying

diagram.

DE

Assembly

Burner head

Burner housing

Fitting the burner housing

·

Dismantle the mixing unit before fitting

the burner housing.

·

Undo the fixing screw (M10 counter

nut and Allen screw) on the side of

the unit (opposite the gas connection)

and withdraw the mixing unit.

If the burner housing hangs below the

burner head axis, proceed as follows:

·

Unscrew and remove the two lower

nuts on the burner housing and

unscrew the two upper nuts as far as

possible.

·

Place the burner housing sloping

diagonally forwards and fit the two

upper bolts into the two slots in

the burner head flange.

·

Press the burner housing against

the burner head flange and tighten

the 4 nuts.

The housing can be mounted above

the axis of the burner head if

required. In this case, the procedure

must be reversed.

No other positions for the burner

housing are possible.

Fitting the burner head

·

Screw M10 stay bolts into the

burner plate/boiler door and add the

insulation. If the bolt circle is <260,

cut slots to the required size.

·

Fix the burner head with 4

hexagonal nuts M10

Blast tube installation depth

On boilers with reverse firing or on

three-pass boilers, the blast tube

installation depth must be complied with

for correct operation. The following

standards are to be reconciled with the

boiler manufacturer’s specifications.

–

Boiler in reverse firing chamber

Dimension A = Boiler front to reverse

edge of second pass

–

Three-pass boiler

80-190 mm

Insertion depth

-20 to +90 mm

Insertion depth

Ø a

Ø b

c

d

195

220-260

M10

45°