4

09/2005 - Art. Nr. 13 019 526A

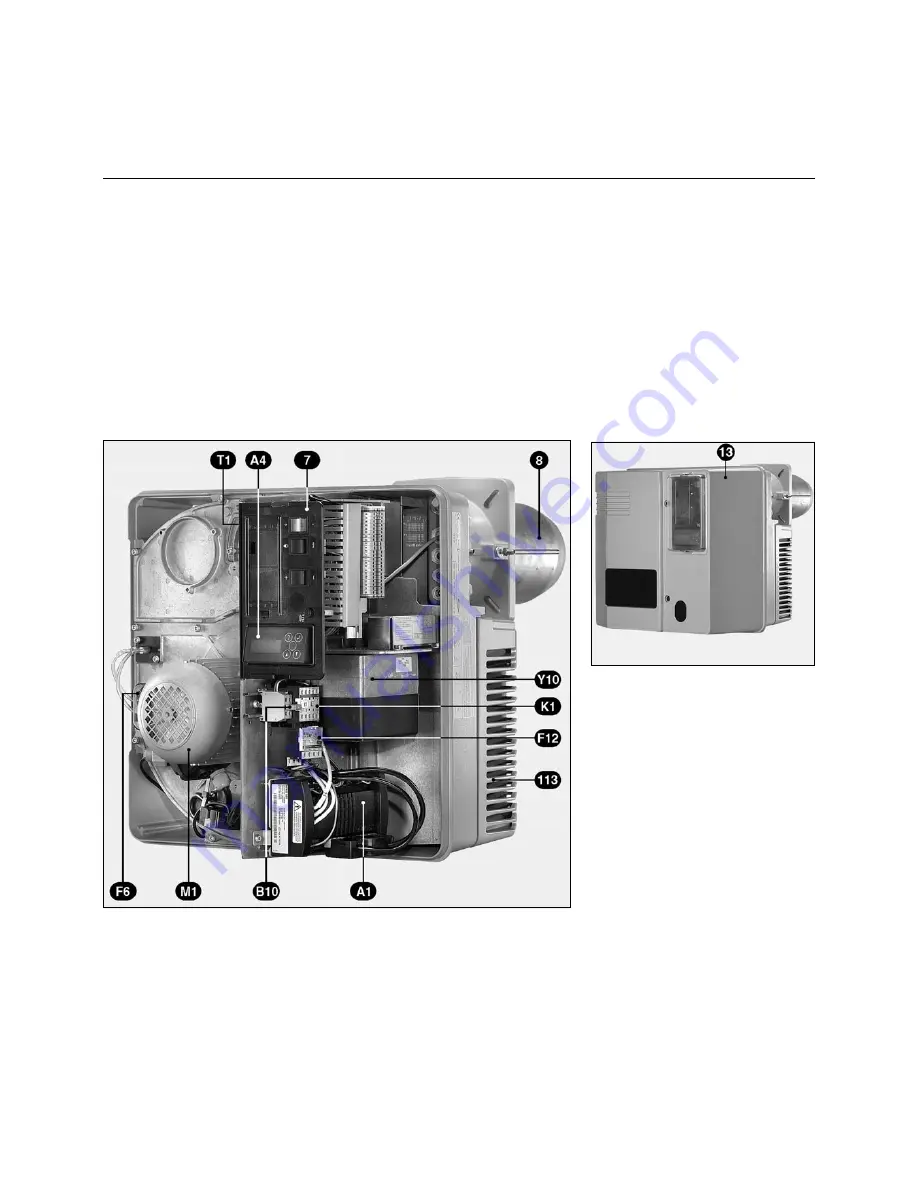

Overview

Description of burner

Burner description

The G 05.700/1000 MODULO burners

are low emission, modulating gas

burners with a monoblock type

electronic connection. They are suitable

for use with all heat generators in

accordance with DIN 4702/EN 303

within the respective performance range.

Scope of delivery

The burner is supplied in three

packaging units:

·

Burner housing with operating

instructions, flow diagram, spare parts

list, combustion chamber board.

·

Burner head with flange seal and

fixing screws.

·

Gas valve assembly with gas throttle

module, DMV gas valve with built-in

pocket filter or with external filter,

connection parts, screws, seals.

Optional accessories:

–

Separate air intake box

–

Air intake silencer

–

Gas stop valve

–

Thermal safety cut-out valve

–

Compensator

–

Power regulator

–

Potentiometer

–

Test burner

–

Pressure gauge

A1

Combustion control unit

A4

Display and operating unit

B10 Ionisation bridge

F6

Air pressure switch

F12 Protective motor relay

K1

Motor contactor

M1 Burner motor

T1

Ignition transformer (concealed)

Y10 Servomotor air flap

7

Control panel

8

Blast tube

13

Burner cover

113 Air box