01/2009 - Art. Nr. 4200 1016 3900A

26

Start up

Checks before start-up

Ionisation current measurement

Checks before start-up

Before commissioning the burner, the

following checks and inspections are to

be carried out

- Operating instructions of the heat

generator manufacturer

- Setting of

- temperature regulator

- pressure regulator

- limiter

- safety guard

- Gas connection pressure min. 20 mbar

flow pressure.

- Leaks in the gas supply elements

- venting of the fuel supply pipes.

- Open flue gas ducts, an adequate

supply of fresh air.

Burner program sequence test

without flame formation

The burner control unit activates the first

time the sealing test is activated. Gas

pressure is required for this. In order to

check the entire sequence test initially

without flame formation, close the gas

manual shut-off valve again once the

sealing test is complete.

Proceed as follows:

• Open the manual shut-off valve

• Activate the boiler controller to start

the heat generator

• Follow the sealing test as performed

on the display

• Once the second valve is open, close

the manual shut-off valve again.

• The program sequence test runs until

a safety shutdown is triggered

(malfunction lamp lights up) once the

safety period has elapsed or a

shortage of gas occurs

• Disconnect the power supply to the

burner

• Open the manual shut-off valve again,

supply the burner with voltage again, if

necessary unlock and restart.

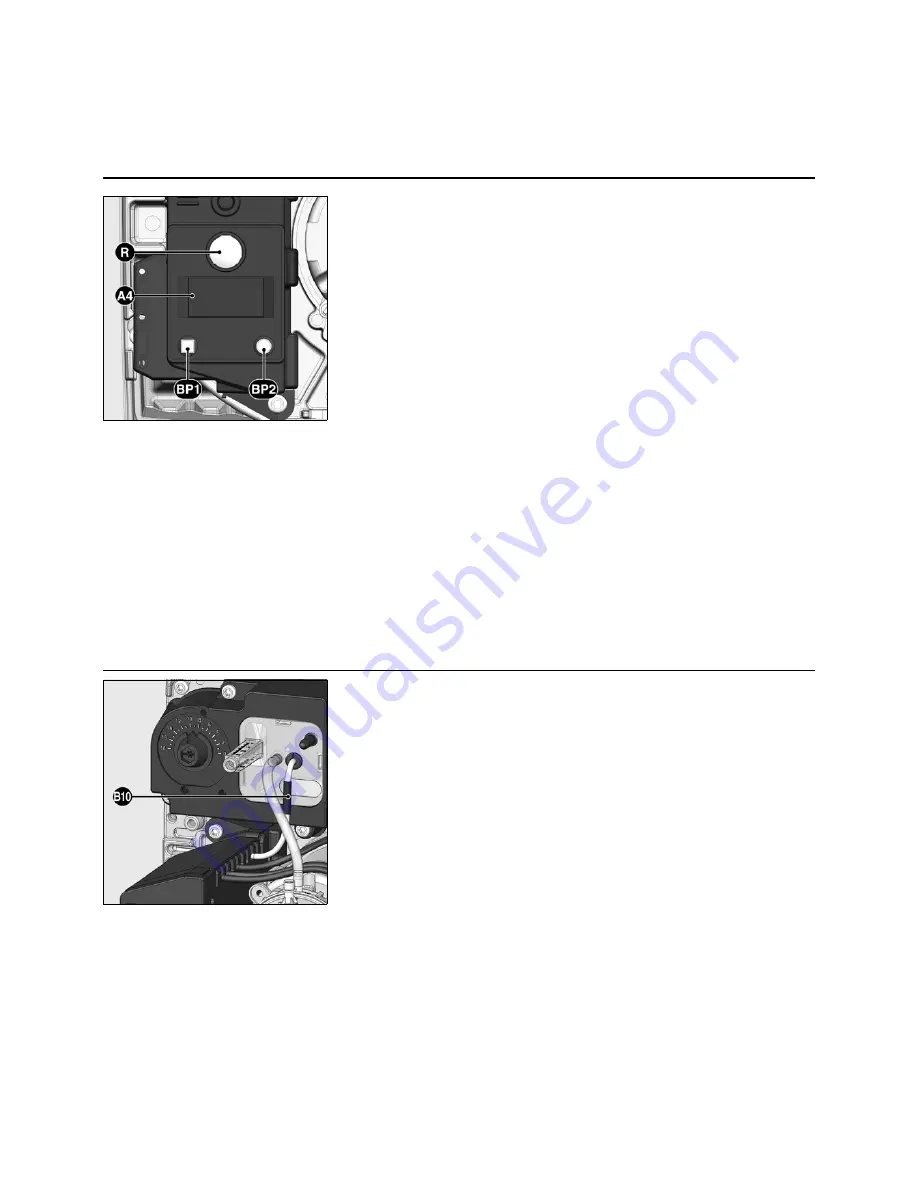

Ionisation current measurement

The ionisation current can be measured

at the measuring point intended for this

purpose. To do this, remove measuring

bridge

B10

and connect a multimeter

with a measuring range of 0-100 µA.

The monitoring current must be at least

8 µA.