05/2005 - Art. Nr. 13 018 106A

48

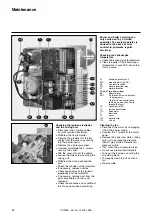

Checking the ignition electrodes

and the mixing unit.

·

Disconnect the 2 ignition cables

from the ignition transformer.

·

Withdraw the flame monitor.

·

Remove the grommet for the two

cables from the cover by pressing

into the burner head.

·

Remove the oil pressure pipes.

·

Unscrew completely the 3 screws

securing the cover.

·

Slip the cover off over the cables.

·

Loosen the side screw securing the

mixing unit.

·

Withdraw the mixing and ignition

unit.

·

Check the condition of the turbulator.

·

If necessary, replace nozzles.

·

Check the position of the ignition

electrodes and the turbulator.

·

If necessary, remove dust from the

parts accessible with the cover

removed.

·

Check the presence and condition of

the O-ring seal when assembling.

Cleaning the fan

·

Disconnect the motor by unplugging

it from the power supply.

·

Unscrew the 7 screws of the motor

panel.

·

Remove the panel and motor, taking

care not to damage the pressure

take-off pipe of the differential air

pressure switch.

·

“Dry” clean the air pressure pipes.

·

Do not use pressurized materials.

·

Take out the 4 screws securing the

air guiding piece.

·

Thoroughly clean the air duct and

fan.

·

Re-assemble.

Burner and boiler servicing can

only carried out by a trained

specialist. The system operator is

advised to take out a service

contract to guarantee regular

servicing.

Checking the exhaust gas

temperature

·

Check the exhaust gas temperature.

·

Clean the boiler if the exhaust gas

temperature is over 30 K above the

start-up value.

Maintenance

A1

control and safety unit

B10

measure point [µA DC]

F6

air pressure switch

F12

motor protection relay

K1

motor protection

K5-K6-K7 time delay switches

M1

blower motor

SA1

On the control unit, display of:

- the programm,

- the faults: red control lamp

lights up, and push button to

release the fault.

TC

control panel

TC

T1

ignition transformer

Y10

servomotor

9

blast tube

15

cover

102

motor/pump

113

air box