09/2018 - Art. Nr. 4200 1092 1400A

22

Operation

Operating mode

Safety function

Description of the function

- Control thermostat requests heat.

- The control program of the control unit

starts if the air pressure switch contact

is in the rest position and the gas

pressure switch signals sufficient gas

pressure.

- Burner motor operational

- Pre-ventilation period of 24 s

During the pre-ventilation time

- the air pressure is monitored

- the combustion chamber is monitored

to detect any flame signals.

At the end of the pre-ventilation time

- the ignition is switched on

- the main and safety solenoid valves

are opened.

- burner start-up

Monitoring

The flame is monitored by an ionisation

probe. The probe is fitted with insulation

to the gas head and is routed through

the turbulator into the flame zone. The

probe must not have any electrical

contact with earthed parts. The burner

switches to malfunction if a short circuit

occurs between the probe and the

burner earth. During burner operation,

an ionised zone is produced in the gas

flame through which a rectified current

flows from the probe to the burner tip.

The 2

nd

stage ionisation current must be

at least 7 µA.

Safety functions

- If no flame is produced when the

burner is started (gas release), the

burner will be switched off at the end

of the safety time lasting no more than

3 seconds and the gas valve closes.

- In the event of flame failure during

operation, the gas supply is cut off

within a second and the automatic

combustion control unit triggers a

safety shutdown.

- The burner does not operate if there is

a lack of air during the pre-ventilation

period. A safety shutdown is triggered.

- A safety shutdown also occurs if there

is a lack of air during operation.

- The burner does not operate if there is

a lack of gas. If there is a lack of gas

during operation, the gas valve closes

and the burner switches off. There is

no safety shutdown. The burner starts

automatically if the gas pressure is

restored.

CH note

In accordance with SSIGE instructions,

it is compulsory to install a gas safety

valve (mark

1

) in the pipe

DE Note

In compliance with the reference layout

applicable to boiler rooms, sites with gas

furnaces must be fitted with a thermal

gas shut-off valve (mark

1

).

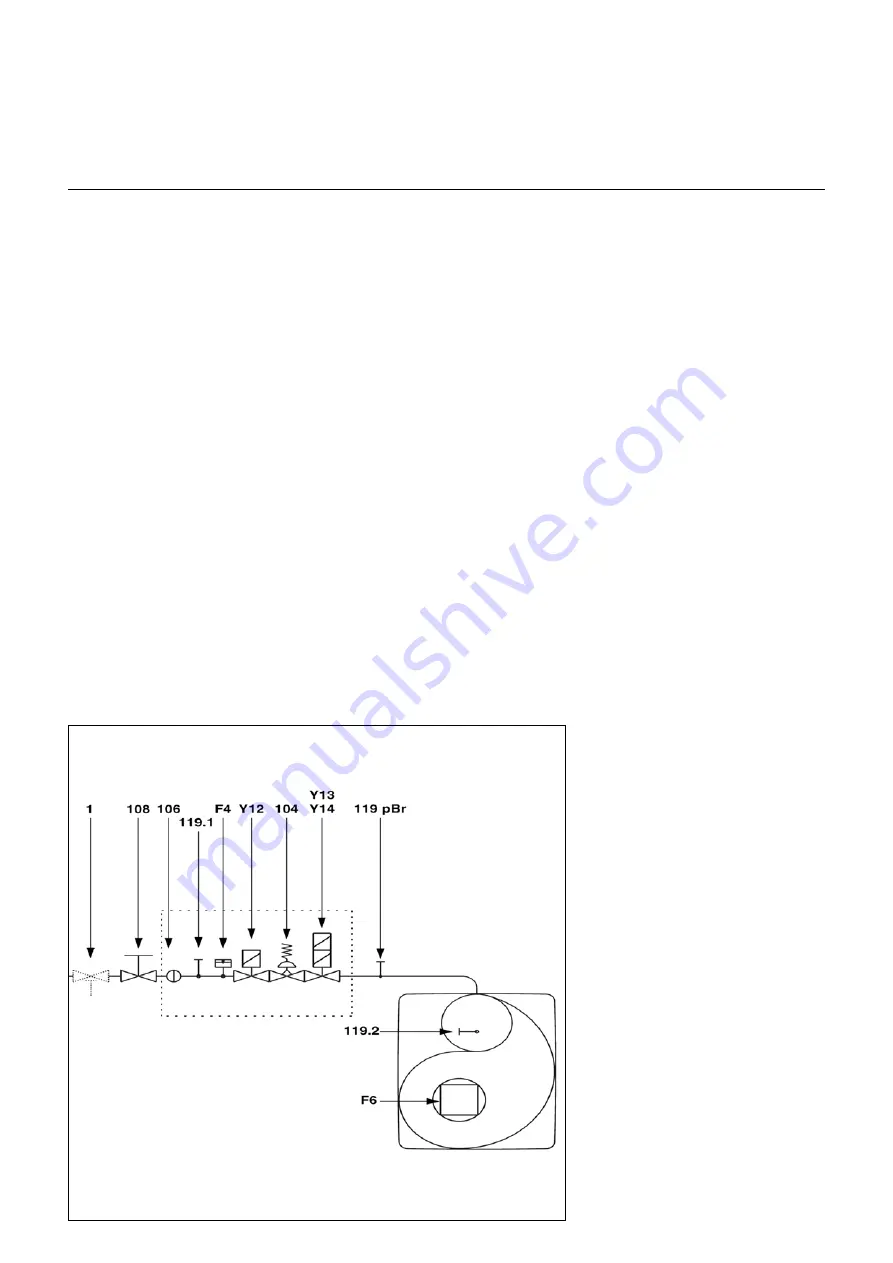

F4

Gas pressure switch

F6

Air pressure switch

Y12 Safety solenoid valve

Y13 Solenoid valve, 1st stage

Y14 Solenoid valve, 2nd stage

1

Thermal shut-off valve (to be

installed by the installer)

104 Gas pressure regulator

106 Screen

108 Gas cut-out valve (to be installed

by the installer)

119pBrGas pressure measuring point at

the valve outlet

119.1Gas pressure measuring point

upstream of the valves

119.2Air pressure measuring point

Compact train