06/2011 - Art. Nr. 13 018 118C

38

Assembly

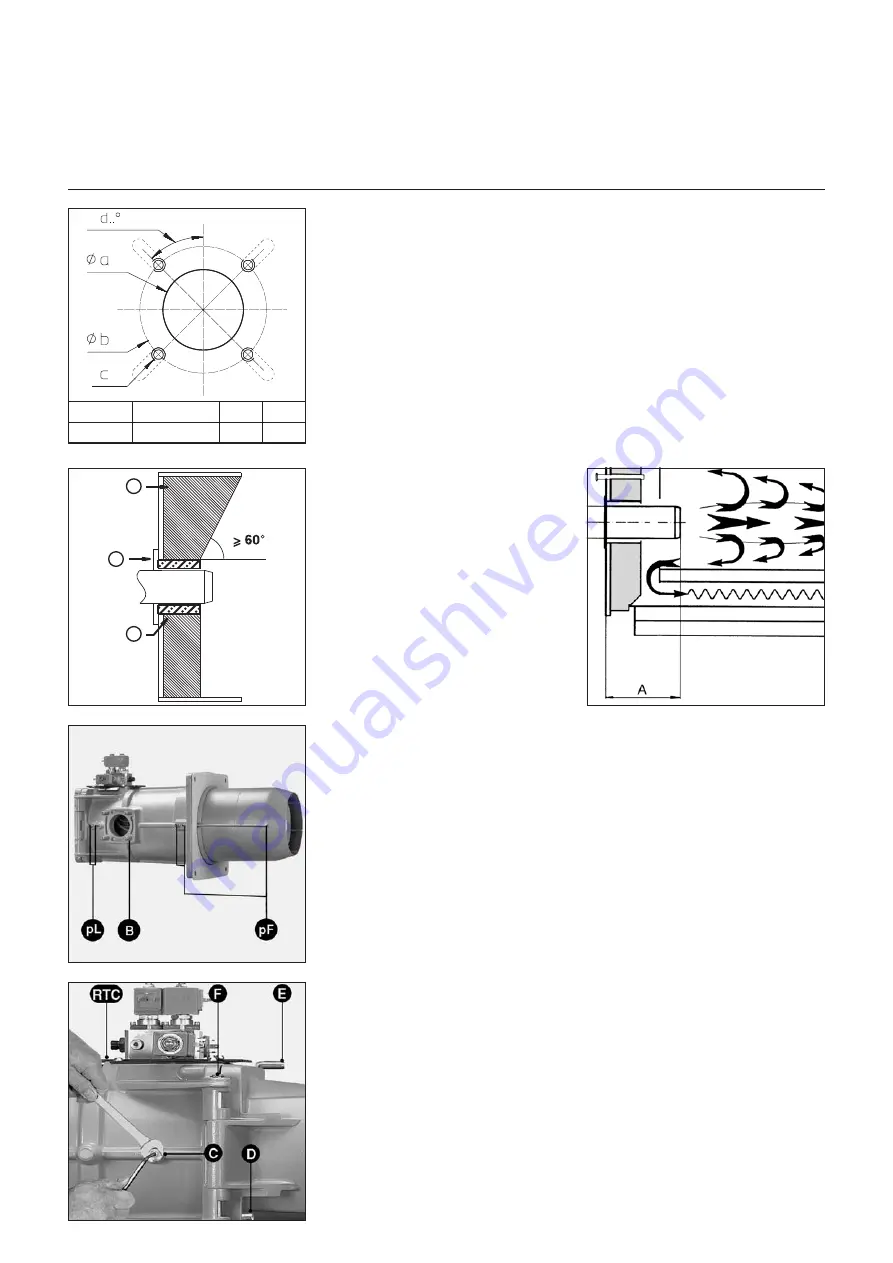

Burner assembly

Burner tube insertion depth and

brickwork

On heaters without a cooled front wall,

unless the boiler manufacturer indicates

otherwise, brickwork

5

as shown in the

illustration is required. The brickwork

must not protrude beyond the leading

edge of the blast tube, and should have

a maximum conical angle of 60°. The

space between the brickwork and

burner should be filled with an elastic,

non-inflammable insulation material

6

.

On boilers with reverse firing, minimum

insertion depth

A

of the burner tube

should be observed as per the instruc-

tions of the boiler manufacturer.

5

4

6

Fitting the burner head

•

Prepare the burner plate/boiler doors

as per the drawing.

•

Stipulate interior diameter

a

250 mm.

•

Four M12 holes (300-400 mm

diameter circle) are required, as

indicated in the accompanying

diagram.

•

Screw M12 stay bolts into the

burner plate/boiler door and add the

insulation. If the bolt circle is <400

mm, cut slots to the required size.

•

Fix the burner head with 4

hexagonal nuts M12.

•

The space between the blast tube

and the door insulation must be clad

in fire-resistant material.

N.B.:

Take care not to obstruct the

furnace pressure release pipe, pF.

Fitting the burner housing

If the burner housing hangs below the

burner head axis, proceed as follows:

•

Fix the burner housing to the burner

head using fixed (opposite the gas

connection) axis

F

.

•

Connect the two ignition cables.

•

Close the burner with axis

E

.

•

Tighten safety screw

D

.

The housing can be mounted above

the axis of the burner head if required.

No other positions for the burner

housing are possible.

•

Connecting the oil hose to the oil filter.

•

Connect the oil pressure conduit

from the pump to the oil magnetic

valve block.

•

Check the oil hose connections for leaks.

•

Create an electrical plug-and-socket

connection between the hydraulics

block and the burner.

Ø a (mm)

Ø b (mm)

c

d

250

300 bis

400

M12

45°

Summary of Contents for VGL 06.1200 DP

Page 26: ......