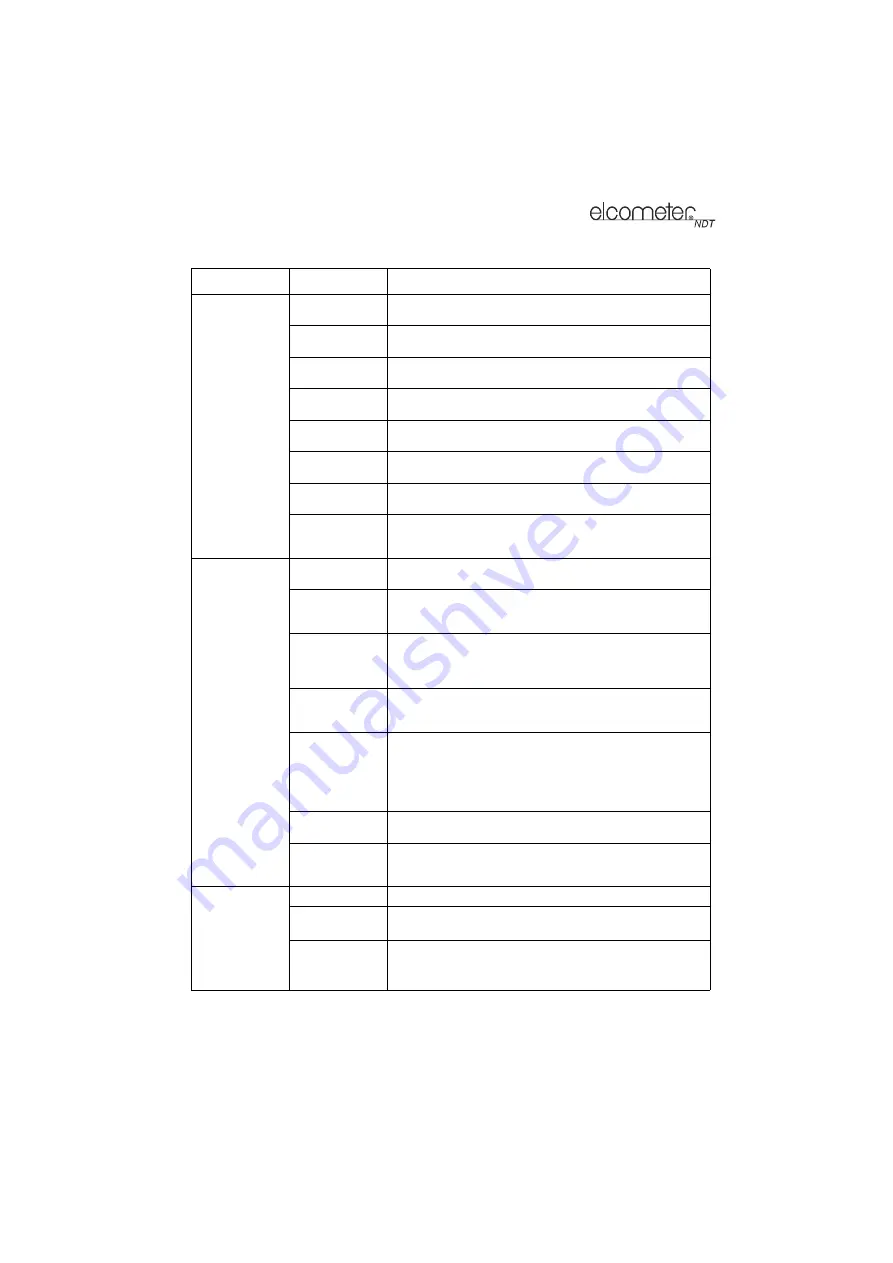

33

DISP

(DISPLAY)

VIEW

Choose between RF wave, RECT (rectified) wave, BSCAN

(cross section), and DIGITS (large digits) views.

DELAY

(B-START)

Adjust where the left side of the display window starts

according to thickness, in inches or millimetres.

RANGE

(B-DEPTH)

Set the overall depth of the viewable measurement area. It

functions a lot like a zoom on a camera.

B-SCAN

SPEED

Adjusts the scroll speed of the B-Scan.

Scale is 0-10 where 10 is the fastest. Default setting: 6.

UNITS

Toggle between Metric (millimetres) or English (inches)

units.

CONTRAST

Adjusts the brightness of the display.

Scale is 0-20 where 20 is the constrast.

RECT WAVE

Toggles between an outlined or filled view option when the

display setting is in RECT (rectified) wave mode.

DETECT MARK

Choose the format of the vertical line on the RF and RECT

measurement screens which shows the detection point:

Line, Box, Dots, None.

TUNE

MEASURE

MODE

Choose which measurement mode to use.

POLARITY

(ABDL only)

The gauge operates on a zero crossing detection principle.

This feature toggles which stroke of the cycle the crossing

detection uses, either positive or negative.

PULSE

(ABDL only)

Your gauge has adjustable pulse width for both high

penetration and resolution applications. The pulse width

refers to the duration of time the pulser is on. The options

are SPIKE, THIN, and WIDE.

PULSER VOLT

(ABDL only)

Provides a 50 V cut/boost to the pulser. The standard setting

is 150 V. Provides greater penetration for difficult material

types, or increased resolution on noisy materials.

ATTN

(ABDL only)

Provides 20dB attenuation or 20dB amplification of signal

strength. Provides increased or decreased amplifier

strength by a power of 10 (20dB). This attenuation value is

added to the gain value. Therefore, if the attenuator is

increased to 20dB, this value is added to the value of the

gain setting.

GAIN

Increases or decreases the overall amplitude of the signal.

Gain is similar to the volume control on a stereo receiver.

AGC

When operating in E-E or E-EV mode, the gauge adjusts the

gain automatically. Alternatively, the AGC can be manually

controlled.

GT1

(GATE 1)

(ABDL only)

GATE1

Sets the start of the gate, according to time/distance.

GATE1 WIDTH

Sets the overall width of the gate, in terms of distance, from

the starting value of Gate1

THRESHOLD1

Sets the sensitivity level of Gate1. The amplitude of the

signal must reach or exceed this threshold level before a

measurement is detected.

Menu

Function

Description