32

en

For full details of the Elcometer NDT range of transducers contact your local Elcometer NDT

supplier, or visit the Elcometer NDT website www.elcometerndt.com

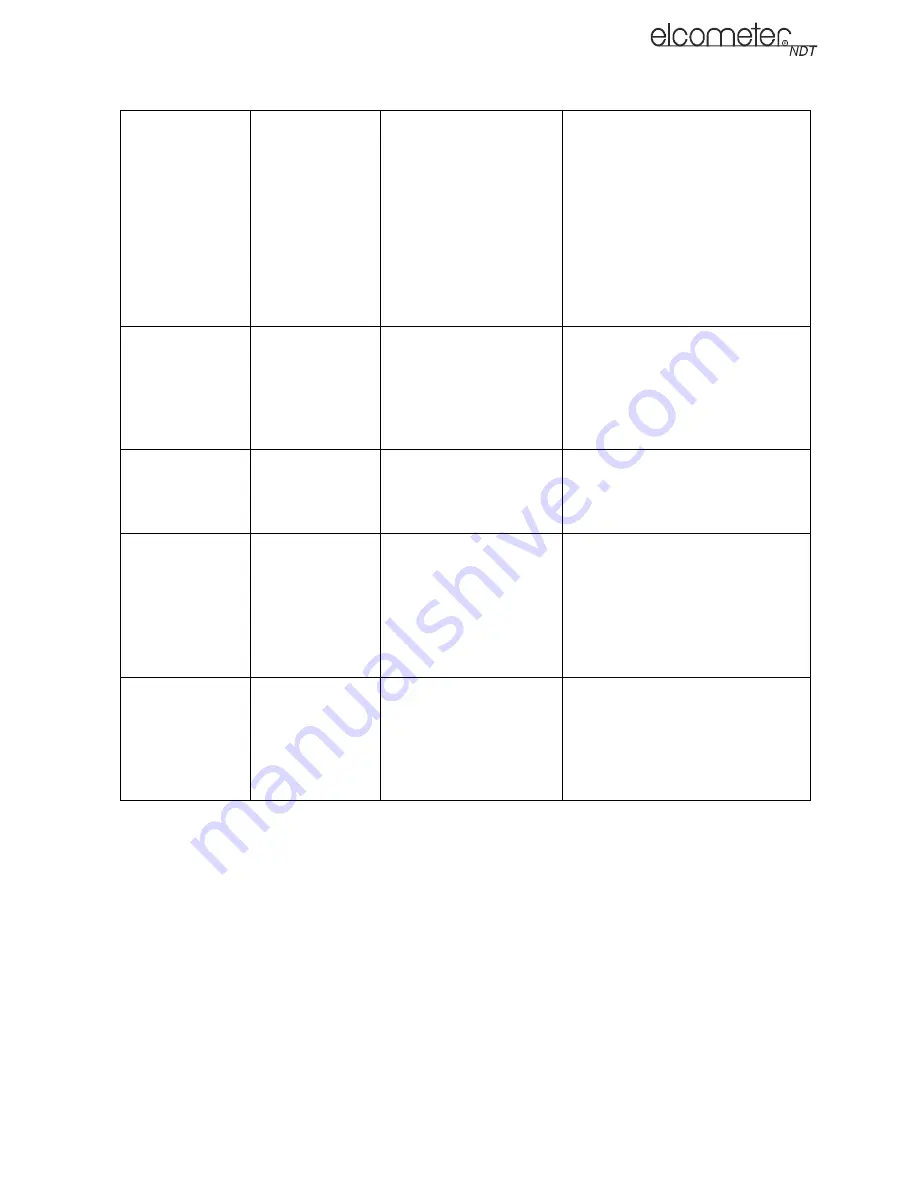

Material

thickness

measured

through a coating

ECHO-ECHO

(E-E)

Special high damped

transducers are

required; typically the

3.5MHz, 5MHz, and

7.5MHz hi damped

transducers.

These transducers are suitable

for use in both pulse-echo and

echo-echo modes. This enables

you to measure overall material

thickness using the Echo-echo

mode, and then switch to pit

detection mode (Pulse-echo)

without changing transducers.

Thin materials

PULSE-ECHO

(P-E)

High frequency

transducers are

required; typically the

7.5MHz and 10MHz

models with extra

resolution.

The higher frequencies provide

greater resolution and a lower

minimum thickness rating overall.

High

temperature

PULSE-ECHO

and

ECHO-ECHO

Special 2.25MHz and 5

MHz High temperature

transducers are

required.

Echo-echo mode will eliminate

error caused by temperature

variations in the delay line of the

transducer.

Noisy material

Select a higher

frequency transducer to

reduce this noise -

7.5MHz and higher for

better resolution.

Materials such as titanium,

stainless steel, and aluminium

may produce surface noise. This

is a signal that appears at the

surface of the material when

using a dual element delay line

probe.

Measuring

extreme

curvatures or

areas of

restricted access

Higher frequency

transducers with smaller

diameters are required.

The smallest diameter

uses 3/16" crystals with

a contact area of .250"

Material being

measured

Mode

Transducer type

required

Notes