- 6 -

3.2 Operation

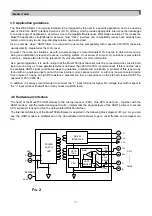

The Mux2700 HSM module implements HART protocol commands and acts as a gateway device between the

Maintenance Workstation (MW) and the field devices. It responds to commands received from the MW (RS-485

interface) as a slave device and issues commands to the HART slaves (field channels) acting as either a Primary

or Secondary Master (according to the HART specification).

A modified version of the HART protocol was implemented on the RS-485 physical layer to obtain a fast and relia-

ble communication with the Maintenance Workstation. In this way, standard HART messages can be used by the

MW for an effective, seamless integration of field devices from different manufacturers.

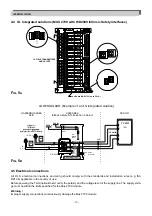

The Mux2700 can continuously poll each connected field device the get the specified primary (or secondary) HART

variable, automatically updating the internal data-base. This is called

scan

operation, and can be enabled or disa-

bled by the Maintenance Workstation (the Mux are factory set in the “Scan-Off” condition). When in the “Scan-On”

mode, the MW can generate a warning message whenever a field device stop communicating (e.g. because it is

disconnected from the loop).

At power-up, the Mux2700 always performs a

locate

activity, that is to say, it polls all the 32 channels to find any

connected – and communicating – field device and to rebuild the required, internal access tables. The locate acti-

vity can be started also by the Maintenance Workstation, and this is usually required to be able to communicate

with a new field device connected to the Mux after power-up. The locate time can range from 15 to 60 seconds,

depending on the specified retry counts (the Mux are factory set with a retry count = 3, resulting in around one

minute of locate time).

In addition to providing access to the HART-capable field instruments, the Mux2700 module is itself, in all respect,

an HART device with parameters and internal functions available to the user (e.g. Tag, Description and unique DIN

– Device Identification Number).

3.3 LED indications

The information provided by the Mux 2700 LED (mounted at the panel front) is summarised in the following table:

3.4 Power-up sequence

In the following, the normal Mux 2700 power-up sequence is described. This is always the standard power-up

behaviour, unless SW8 (at the panel front) is set into the Test position.

•

Immediately after power-up, the Green LED goes immediately On.

•

An internal

self-test

is then performed and, if any problem is detected, the Red LED goes fixed On (on some

Mux versions, the Green LED could blink during self-test).

•

The Yellow LED then start blinking, indicating that the Mux 2700 is performing the

locate

activity, that can last

up to around one minute (N.B. when the field multi-drop option is available and active, the locate time could be

up to15 minutes).

•

The Yellow LED should then go Off, unless the

scan

operation is enabled or the Maintenance Workstation is

directly communicating with a field device.

IM-ENG-116/GB

Colour

Name

Function

Yellow

HART TX

ongoing HART communication with field devices

Green

PWR ON

supply indicator (can blink at power-up)

Red

FAULT

internal fault indication (power-up detection only)