Centrifuge Extractor 1500, Centrifuge Extractor 3000

45-3810, 45-3815

5

9907X0071 Issue 2

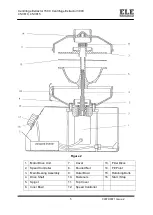

Figure 2

1. Motor Drive Unit

7.

Cover

13. Filter Discs

2. Speed Controller

8.

Knurled Nut

14. Fill Point

3. Main Bearing Assembly

9.

Outer Bowl

15. Retaining Bolts

4. Drive Shaft

10. Fasteners

16. Start / Stop

5. Spigot

11. Top Cover

6. Inner Bowl

12. Speed Controller