Centrifuge Extractor 1500, Centrifuge Extractor 3000

45-3810, 45-3815

8

9907X0071 Issue 2

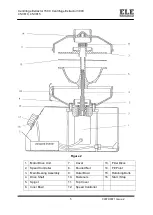

6.1.4 Place a low ash filter paper ring (13) on the lip of the bowl (6), place the cover (7) in

position and clamp the assembly using nut (8).

6.1.5 The assembly can be left for up to 1 hour to allow the solvent to take the bitumen into

solution.

6.2 Centrifuge Process

6.2.1 When ready place the bowl assembly onto the drive shaft (4) ensuring that the slot in

the base of the bowl engages with the driving spigot (5).

6.2.2 Place the cover (11) over the outer bowl and lock in position using the three fasteners

(10).

Note: It is important to ensure that this operation is carried out correctly and that the

cover is properly locked in position.

6.2.3 Start centrifuging by slowly increasing the speed rotating the speed controller

clockwise.

6.2.4 Only proceed to maximum speed when the initial flow of solution from the bowl slows

to a trickle.

6.2.5 When it is considered that drainage is complete, turn the speed controller (12) to the

brake position (fully anti-clockwise).

6.3 Subsequent solvent additions

6.3.1 After centrifuge has stopped, add a further 200 ml of solvent through the top of the

cover (11) at fill point (14).

6.3.2 Allow a few minutes for the solvent to mix with the aggregates in the bowl and then

repeat the centrifuge operation (5.2.3 to 5.2.5).

6.3.3 This operation should be repeated at least twice more or until the solution is clear, or

a light straw colour.

6.4 Weighing and drying

6.4.1 The use of the bowl assembly as part of the quantitative extraction of bitumen from

bituminous mixtures requires the careful weighing of the bowl and ingredients at

various stages of the test.

6.4.2 The operator should follow the instruction details in the relevant national Standards

document.

6.4.3 To ensure accurate and repeatable results, it is important to always keep the inner

bowl and cover assembly clean and dry.

7

Hazards to Health

7.1

Inhalation

Although methylene chloride is not known to cause any permanent organic injury, it

can have anesthetic effects, and inhalation of its vapors may cause nausea,

headaches, drowsiness, or can prove suddenly fatal if exposure has been severe.

Methylene chloride is a volatile liquid, even at normal room temperatures, and the

concentration of vapor in the atmosphere can increase rapidly, particularly in confined

spaces. Good general background ventilation is therefore required where methylene

chloride is to be used and, in addition, extraction vents may be required close to the

source of any vapor emissions and at ground level, where the heavy vapor tends to

collect.