CBR-Test 50

24-9150

Original Instructions

5

9901X0237 Issue 5

1

Safety

This equipment has been tested by ELE International and is safe to use providing that

the proper safety precautions are observed:

Do not use this equipment in any manner, other than as specified in this user

manual; misuse may result in serious injury to personnel.

Do not attempt to operate the equipment with covers removed. Only connect to

the correct electrical supply.

Refer to Installation section before installing machine.

Do not operate machine with wet hands.

Please read this entire manual before unpacking, setting up, or operating this

equipment. Pay particular attention to all

DANGER

and

CAUTION

statements.

Failure to do so could result in serious injury to the operator, or other personnel, or

damage to the equipment. Ensure all moving parts are thoroughly secured before

attempting any maintenance.

1.1

Symbols

Green or Black

P

ROTECTIVE CONDUCTOR TERMINAL

Equipment safety earthing point

Any contrasting

Color

“

I”

=

S

UPPLY

S

WITCHED

“ON”

“O”

=

S

UPPLY

S

WITCHED

“OFF”

Any contrasting

Color

F

USE

,

F

OR SAFE OPERATION OF THE EQUIPMENT

,

USE

ONLY FUSES WITH RATINGS SPECIFIED

Green or Black

Earth (ground)

TERMINAL

Not for safety earthing purposes but provide an earth

reference point.

Background Yellow;

symbol and outline -

Black

Caution, risk of electric shock

Background Yellow;

symbol and outline -

Black

Caution - refer to accompanying documents

Any contrasting

Color

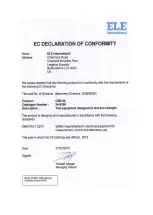

Equipment conforms to the requirements of

European CE Directives, as stated on the

Declaration of Conformity

2

Introduction

This machine has been designed to perform CBR tests which conform to BS 1377

and 1924, ASTM 1883 and to AASHTO T192.

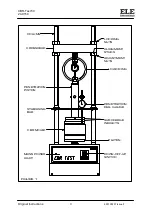

The forces applied are generated by a screw jack via a worm reduction unit driven by

a motor/gear unit. It provides one speed of 1.27 mm/min which satisfies

ASTM/AASHTO Standard and the 1.2 mm ± 0.2 mm/min of the BS Standard. The

worm reduction unit and motor/gear unit is grease packed on assembly and should

not normally require further lubrication.

Rapid adjustment of height of the loading platen is achieved by rotating the platen

anti-clockwise to raise and clockwise to lower.

Limit switches are fitted to prevent over travel on the up and down stroke of the

platen.