Sieve Shaker for 200mm or 8 inch and 300mm or 12 inch diameter sieves

80-0200

7

9907X0058 Issue 2

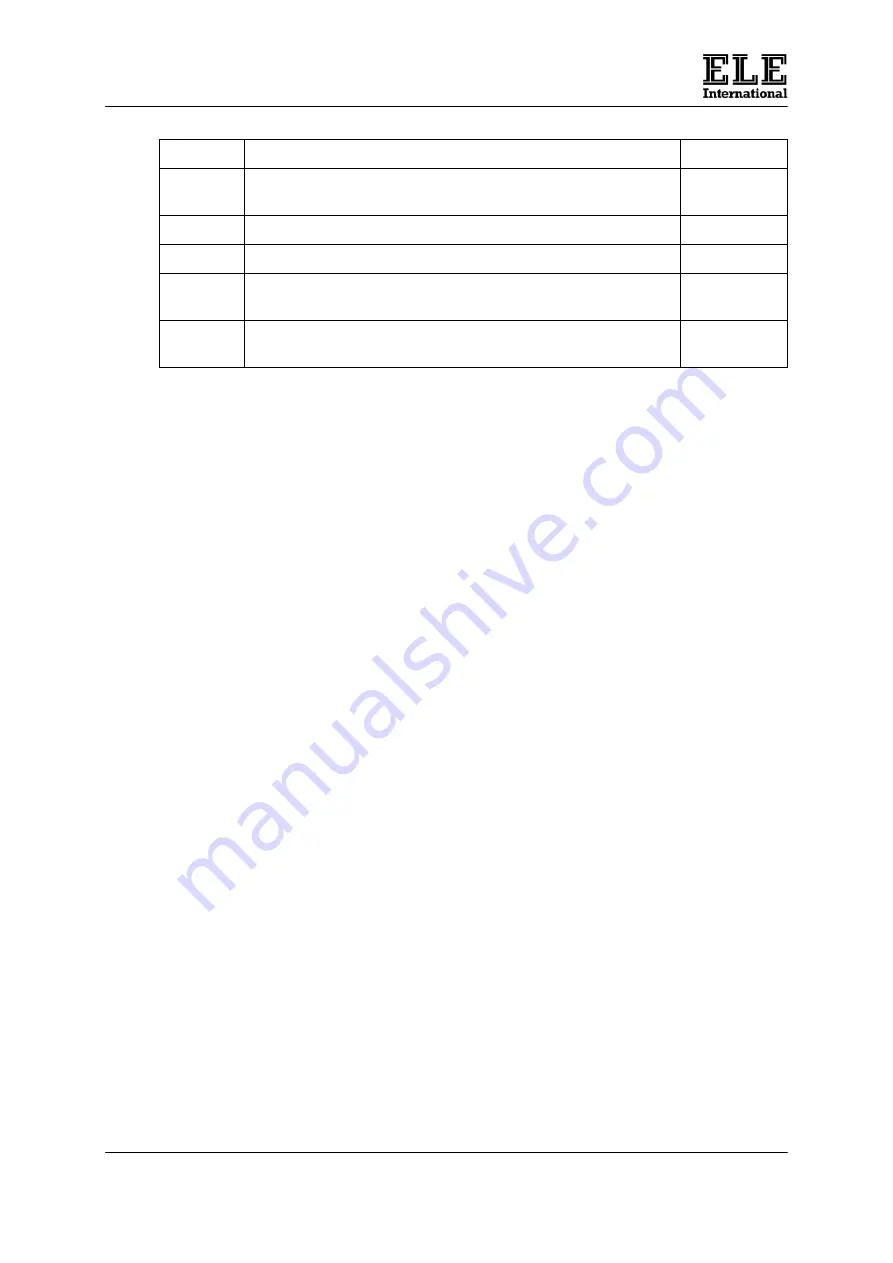

Options

Description

Values

L

Indicates only the countdown in minutes to the end of the

test

---

T

Indicates OR selects sieving duration in minutes

1 - 999 min

H

Indicates OR selects level of vibration

0

– 99

F

Indicates OR selects the ON time when using intermittent

mode

1

– 999 sec

C

Indicates OR selects the intermittent mode ON or OFF

0 = Intermittent

1 = Continuous

Figure 3

4.5

Important Note

:

Make sure the shaker does not make a metallic banging sound as

this will damage the unit. If this should occur then immediately reduce the number in

option “H” in Figure 3 for decreasing the sieving vibration intensity.

4.6

Note

:

When using the intermittent mode option the OFF period is fixed at two

minutes and is not user changeable.

4.7

It is possible to increase or decrease the vibration power while the shaker is running.

Press button 1 and select H, then press button 2 until the digit you want to change is

flashing, then press 3 or 4 depending if the vibration power needs to be increased or

decreased. As the digit changes the vibrating power will change accordingly.

5

Operation

5.1

Apply power to the sieve shaker by switching the mains switch on the control module

to ( I ).

5.2

Sieve stacking (see Figure 1)

Place the receiver centrally into the appropriate recess in the lower vibrating location

plate. Stack the required number of sieves on top of the receiver. Place the sample in

the top sieve and fit the lid.

5.3

Fitting the Clamp Plate (B) (see Figure 1)

Locate the clamp plate onto the two rods and slide down squarely onto the lid of the

sieve stack.

Carefully tighten the hand wheels (A) simultaneously to ensure that the clamp plate is

located square on the lid.

The unit is supplied with a pair of hand wheels for quick adjustment. Standard

threaded hand wheels are also available as an optional extra. Either can be used

depending upon requirements.

5.4

Running the test

5.4.1 Set up the required sieving program as described in Section 4.

5.4.2 Ensure the mains switch is on (d

isplay should be showing “L” on the left hand side,

and a number on the right of the screen will be the current sieving time set in

memory).

5.4.3 Press the control button (5) to start the sieving action. A flashing dash should be

visible in the middle of the display (10), also the indicator (7) will be illuminated.

Summary of Contents for SIEVE-TRONIC

Page 9: ...DIRECTIVE ON WASTE ELECTRICAL ELECTRONIC EQUIPMENT WEEE ...

Page 10: ......