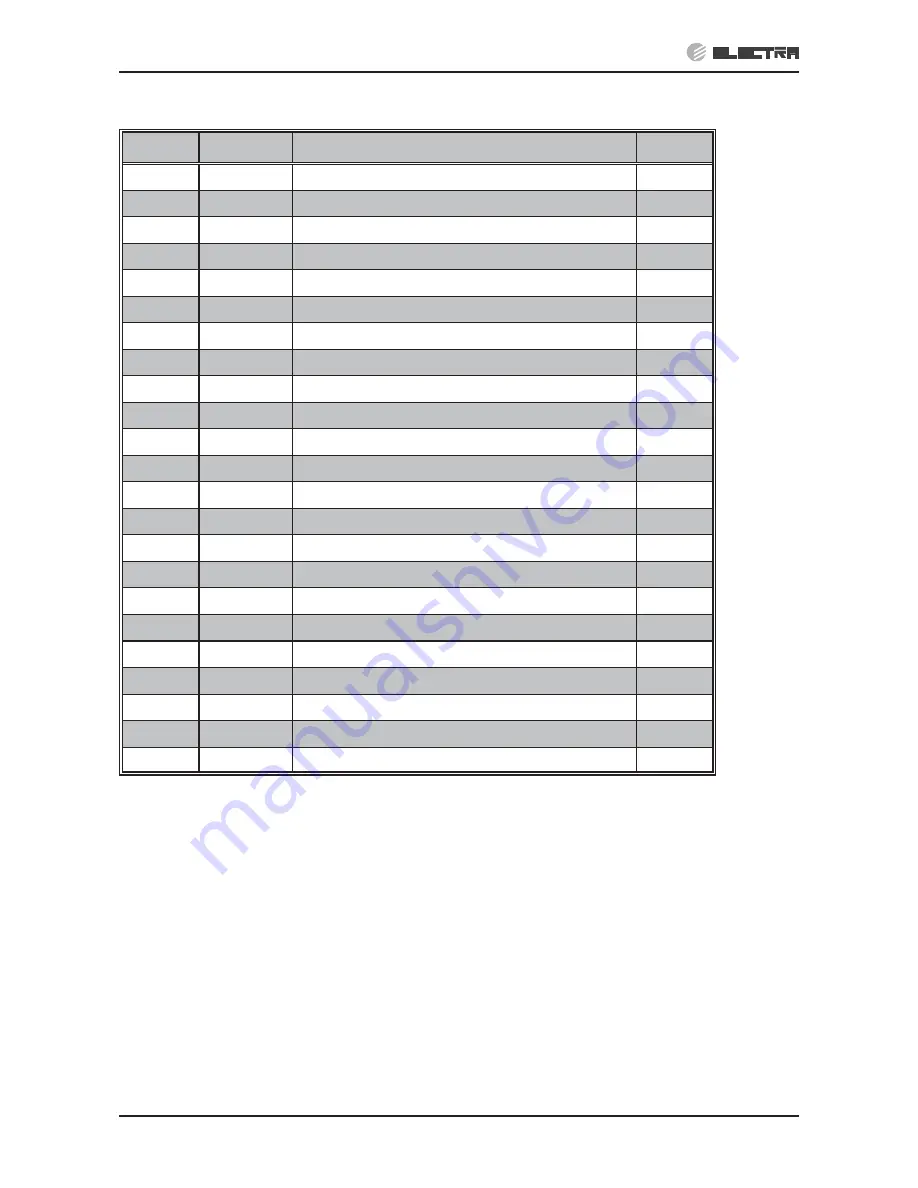

14-20

EXPLODED VIEWS AND SPARE PARTS LISTS

SM DELTA 1-E.0 GB

14.20

Outdoor Unit: OU7-24Z RC/ST 1PH

Part

Description Qty

1

437045

LARGE UPPER COVER CUE

1

2

433280

SIDE PANEL OU7-24 R410A

1

3

436357

SMALL ELECTRICAL COVER CUE

1

4

439329

COVERAIR COLLECTOR

1

5

437091

OU SQUARE FAN GUARD

1

6

433722

BASE ASSY OU7-24C EXPORT R410A

1

7

433285

COIL OU7-24 HDR

1

8

4529604

AXIAL FAN D493x143

1

9

434211

Replace by SP000000266 MOTOR+BRACKET

1

10

433281

SIDE GUARD OU7-24 R410

1

11

436358

TRANSPORT HANDLE CUE

1

12

439342

MOTOR BASE OU7

1

14

438795

COMPRESSOR GP270PAA

1

15

433934

CAPILLARY HEATING ASSY OU7-24 R410A

1

16

433660

TUBING ASSY OU7-24C R410A

1

17

413496

BOARD TPHN 5F (RoHS)

1

18

442007

CAPACITOR 6uF 400V

1

19a

434716

THERMISTOR L1050 (for coil)

1

20

442038

CAPACITOR 50mF 400V P1/P2

1

21

438627

COMPRESSOR WIRING TPHN-5F

1

24

437229

ELECTRICAL BOX TPHN

1

33

442520

VALVE COIL L700 MOLEX-DUNAN

1

44

192207

CONTACTOR 230V, 40A

1

Summary of Contents for DELTA 18

Page 14: ...4 2 OUTLINE DIMENSIONS SM DELTA 1 E 0 GB 4 3 Outdoor Unit OU7 24 OU7 24Z...

Page 21: ...5 7 PERFORMANCE DATA PRESSURE CURVES SM DELTA 1 E 0 GB 5 6 Pressure Curves 5 6 1 Cooling...

Page 22: ...5 8 PERFORMANCE DATA PRESSURE CURVES SM DELTA 1 E 0 GB 5 6 2 Heating...

Page 31: ...8 1 WIRING DIAGRAMS SM DELTA 1 E 0 GB 8 WIRING DIAGRAMS 8 1 Indoor Unit DELTA 18 21 24...

Page 32: ...8 2 WIRING DIAGRAMS SM DELTA 1 E 0 GB 8 2 Outdoor Unit GC 18 1PH R410A...

Page 33: ...8 3 WIRING DIAGRAMS SM DELTA 1 E 0 GB 8 3 Outdoor Unit GC 24 1PH R410A...

Page 34: ...8 4 WIRING DIAGRAMS SM DELTA 1 E 0 GB 8 4 Outdoor Unit OU7 24 1PH R410A...

Page 35: ...8 5 WIRING DIAGRAMS SM DELTA 1 E 0 GB 8 5 Outdoor Unit OU7 24 3PH R410A...

Page 36: ...8 6 WIRING DIAGRAMS SM DELTA 1 E 0 GB 8 6 Outdoor Unit OU7 24Z R410A...

Page 39: ...10 2 REFRIGERATION DIAGRAMS Service Manual ALPHA 10 1 2 DELTA 24 OU7 24 R410A...

Page 40: ...10 3 REFRIGERATION DIAGRAMS SM DELTA 1 E 0 GB 10 1 3 DELTA 24 OU7 24Z R410A...

Page 81: ...14 3 EXPLODED VIEWS AND SPARE PARTS LISTS SM DELTA 1 E 0 GB 14 3 Outdoor Unit GC 18 ST...

Page 83: ...14 5 EXPLODED VIEWS AND SPARE PARTS LISTS SM DELTA 1 E 0 GB 14 5 Outdoor Unit GC 18 RC...

Page 85: ...14 7 EXPLODED VIEWS AND SPARE PARTS LISTS SM DELTA 1 E 0 GB 14 7 Outdoor Unit GC 21 RC...

Page 87: ...14 9 EXPLODED VIEWS AND SPARE PARTS LISTS SM DELTA 1 E 0 GB 14 9 Outdoor Unit GC 21 ST...

Page 89: ...14 11 EXPLODED VIEWS AND SPARE PARTS LISTS SM DELTA 1 E 0 GB 14 11 Outdoor Unit GCN 12 RC...

Page 91: ...14 13 EXPLODED VIEWS AND SPARE PARTS LISTS SM DELTA 1 E 0 GB 14 13 Outdoor Unit GC 24 RC...

Page 93: ...14 15 EXPLODED VIEWS AND SPARE PARTS LISTS SM DELTA 1 E 0 GB 14 15 Outdoor Unit OU7 24 RC 1PH...

Page 95: ...14 17 EXPLODED VIEWS AND SPARE PARTS LISTS SM DELTA 1 E 0 GB 14 17 Outdoor Unit OU7 24 ST 1PH...

Page 99: ...14 21 EXPLODED VIEWS AND SPARE PARTS LISTS SM DELTA 1 E 0 GB 14 21 Outdoor Unit OU7 24 RC 3PH...

Page 101: ...14 23 EXPLODED VIEWS AND SPARE PARTS LISTS SM DELTA 1 E 0 GB 14 23 Outdoor Unit OU7 24 ST 3PH...

Page 106: ...15 4 OPTIONAL ACCESSORIES SM DELTA 1 E 0 GB...

Page 107: ...15 5 OPTIONAL ACCESSORIES SM DELTA 1 E 0 GB...

Page 108: ...15 6 OPTIONAL ACCESSORIES SM DELTA 1 E 0 GB...