10

LEAK TESTING

NEVER USE A NAKED FLAME TO CHECK FOR LEAKS.

NEVER LEAK TEST WHILE SMOKING.

The gas connections on this appliance are leak tested at the factory prior to

shipment.

This appliance needs to be periodically checked for leaks and an immediate

check is required if the smell of gas is detected.

•

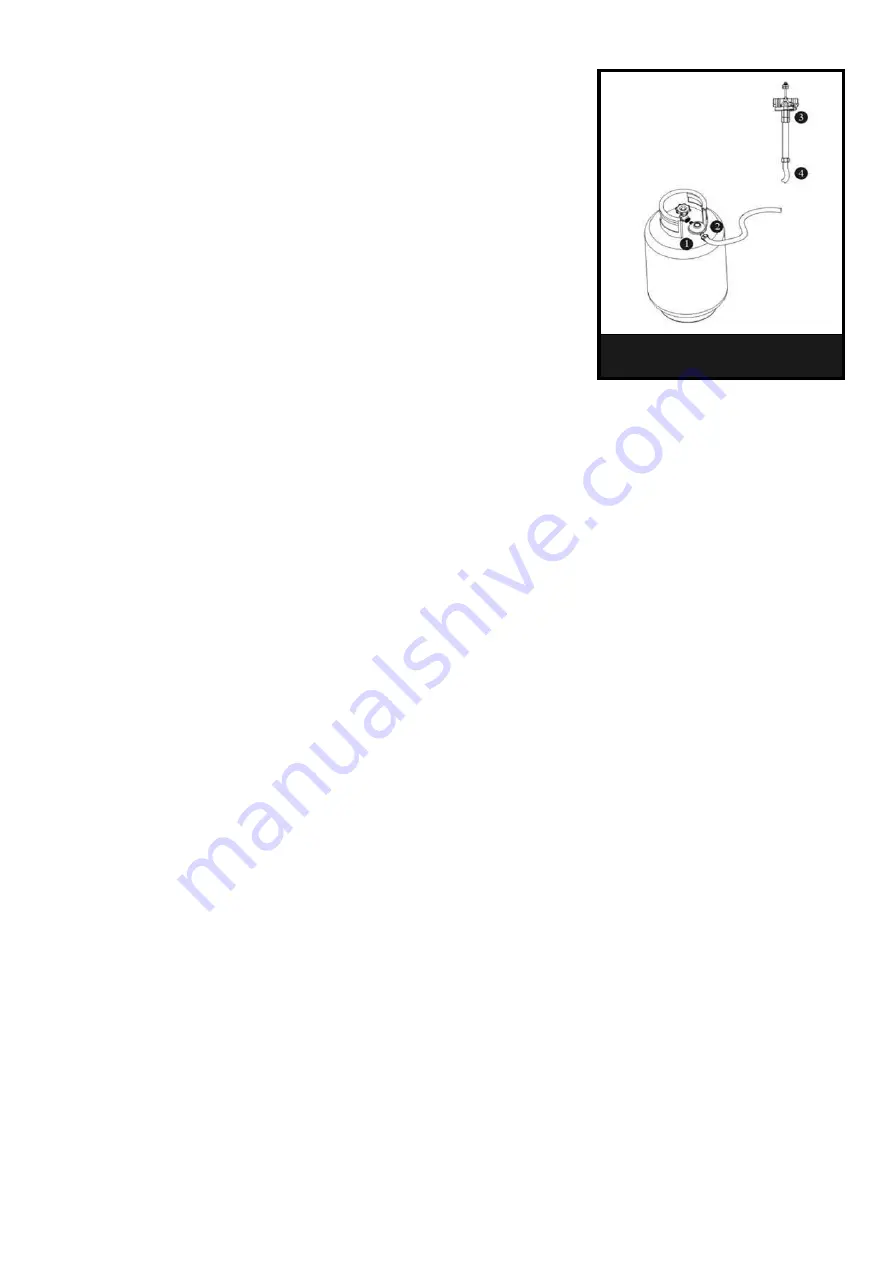

Make a soap solution using 1 part of liquid dish-washing soap to 3 parts

water. The soap solution can be applied with a soap bottle, brush, or rag

to the leak tested points shown in the figure above.

•

The valve of the gas cylinder should be in the

OFF

position. Once the

soapy solution is applied to the gas connections, the valve of the gas

cylinder needs to be turned to the

ON

position.

•

Soap bubbles will begin to form in the soapy solution if a leak is present.

•

In case of a leak, turn off the gas supply. Tighten any leaking fittings, then

turn the gas supply on and recheck.

GAS REQUIREMENTS

•

The regulator and hose assembly used must conform to local safety requirements.

•

Never use a gas cylinder with a damaged body, valve, collar, or foot ring. A dented or rusty gas tank may be

hazardous and should be checked by a gas supplier.

•

Never connect this appliance to an unregulated gas source.

•

When the appliance is not in use, turn the gas cylinder OFF, before disconnecting it.

•

Always perform a leak test on gas connections whenever a cylinder is connected. If bubbles form in the leak test

solution, do not use. Never use a flame to test for leaks.

CONNECTING TO A GAS CYLINDER

•

Use a 9 kg gas cylinder.

Please refer to your gas supplier for suitable gas cylinder.

•

Refer to your gas supplier for instructions on the use of your gas cylinder.

•

Only change gas cylinders outdoors or in a well-ventilated area away from naked flames and any other source of

ignition.

•

The gas cylinder must always be used in an upright position.

•

Close the heater control dial by turning fully clockwise.

•

Close the gas cylinder tap and then attach the regulator onto the gas cylinder.

•

Tighten all connections firmly and with a spanner where appropriate. The cylinder should be located on the cylinder

base.

•

Check for leaks at all joints using soapy water. If a leak is found, tighten the joint and then re-test.

Leak Test Point

①

②

③

④