Summary of Contents for CS700-FG

Page 2: ......

Page 7: ...ELECTRO FREEZE Shake Model CS700 FG Safety Decal Locations v 1 P N HC165126 2 P N HC165025 ...

Page 10: ......

Page 46: ......

Page 48: ......

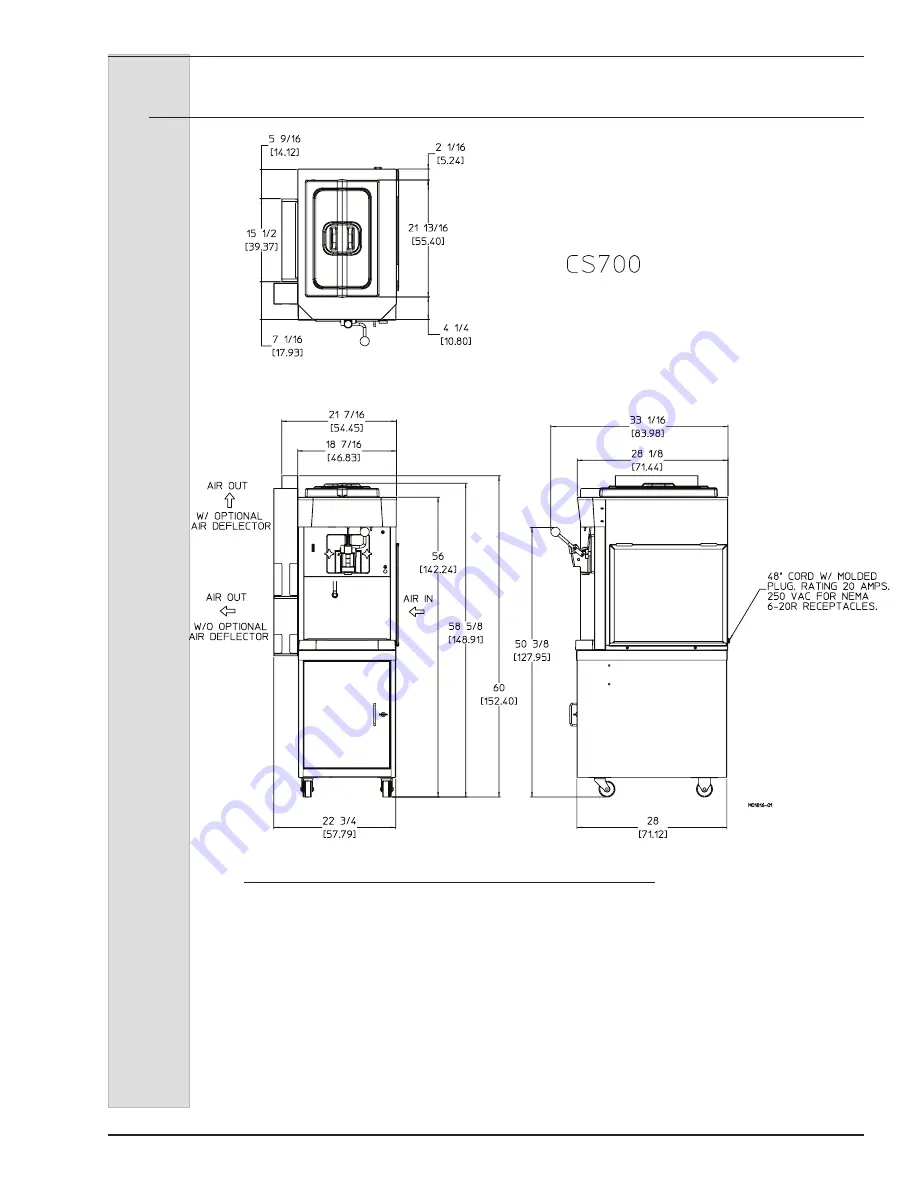

Page 54: ...ELECTRO FREEZE Shake Model CS700 FG 185231 17 6 Figure 7 Side View Sheet 1 of 2 ...