12/20/2017

4

EI505

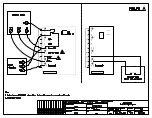

MECHANICAL

INSTALLATION

The heat pump manufacturer's starter collar should be centered over the discharge blower.

Generally the blower shaft is 9Ø

to the facing front of this Electro-Duct. In other words, if you

would be viewing the blower motor shaft, you would see the side of the electrical control box.

Also blower centering means, the approximate 3 inch opening of the blower discharge is

centered under the electric elements. It does not mean the complete blower housing discharge is

centered, only the actual blower discharge opening itself.

In the case of the Econar unit, the Electro-Duct right side extended lip (facing Electro-Duct

control box), simply lapse on the right side of the Econar cabinet and the Electro-Duct center

side hole alignment with Econar cabinet center side screw.

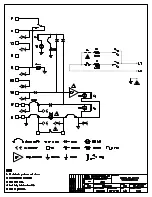

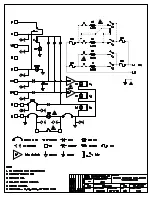

ELECTRICAL

HOOKUP

1. 240 VOLT SOURCE - Locate correct model number and KW size in Table 1 to determine

operating current and minimum source circuit breaker size. According to local codes,

building type, wiring run distance, etc., use the appropriate electric conductor size to

bring over the 240 volt source power. Connect to fuse block/input terminals (10KW is

terminal block only).

2. GROUNDING - Route and install the appropriate size ground conductor between the ground

lug labeled "GROUND" and building service entrance panel ground buss. This must be a

conductor sized according to the total amp rating of the appropriate model. Conduit is

not a adequate ground conductor.

3. THERMOSTAT CONTROL - See drawing EH5Ø3 and previous Functional Description

section for basic hookup:

A. Outdoor stat is not required, factory jumper is provided between "W1" and "X".

B. "W2" is not available on 10KW models.

C. 10KW model can be operated from a two stage room stat ("W1" and "X"). Remove

jumper between "W1" and "X", connect stat "W1" to "W1" and "W2" to "X".