07/24/2007

BL001

•

Handled as the priority zone on multi-zone (EB-ZEA-1) or two

pump (EB-Z2P) controllers

•

Priority switch on, zone 1 active - TS boiler automatically changes

to 150° (or selection 176°) supply water setting

•

All other zones are held off

•

With zone 1 satisfi ed or 60-minute timeout, the boiler automatically

returns to the preset temperature and reacts to the other zones

Low Temp

High Temp

Radiant, slab

Radiant, staple up

Radiant, slab

Baseboard

Radiant, slab

Fan coil

Radiant, slab

Water heater, side arm

Radiant, slab

Hanging unit heater (garage, shop, etc.)

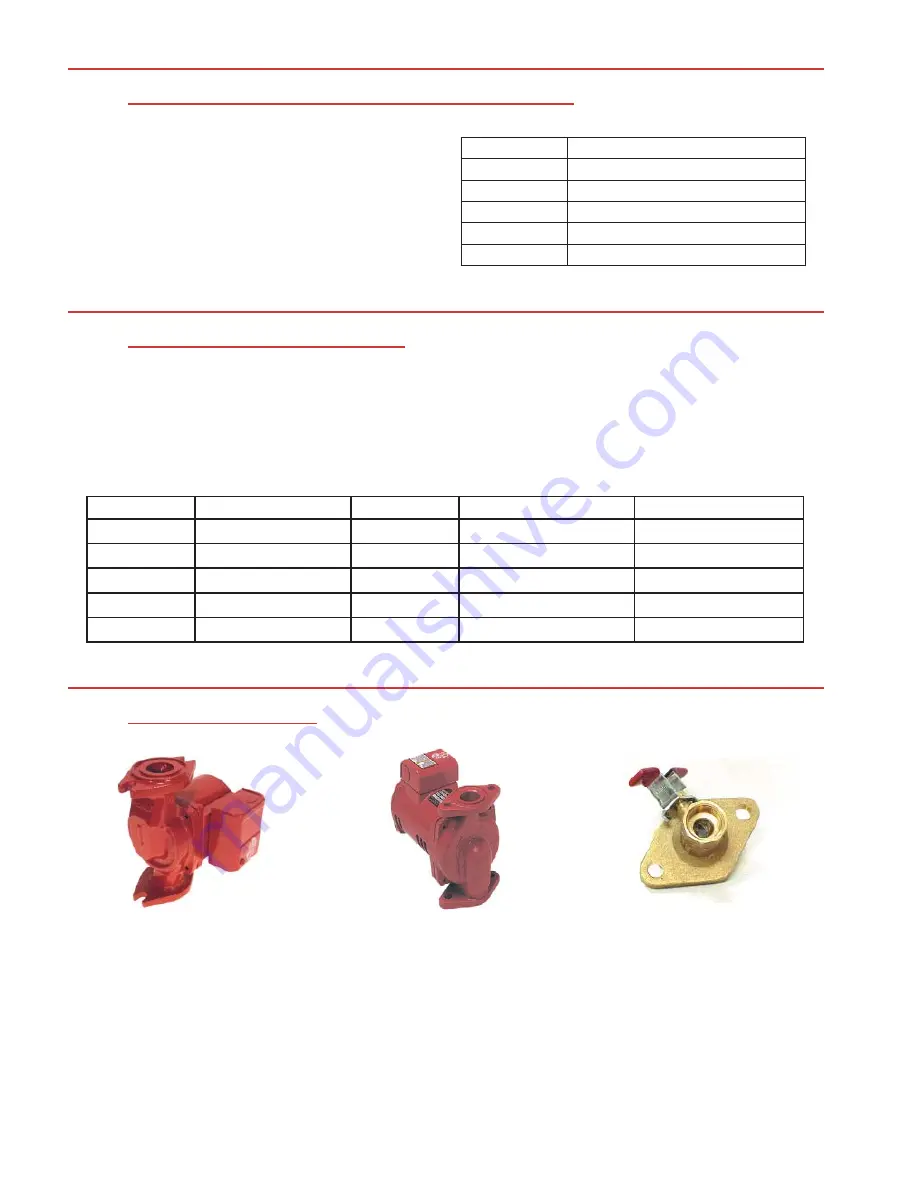

These installation kits provide the critical plumbing components needed for easy installation of the Electro-Boiler.

In addition

to the

items shown in the matrix below, each kit includes all necessary ball valves, drain valve, tees, elbows, nipples, bushings, couplings,

etc. for direct connection to circulator pump and/or manifold.

Electro Industries’ boilers come standard equipped with outlet temperature/pressure gauge, pressure relief safety valve, and when

applicable, the WarmFlo

TM

electronic control sensors. These kits provide the additional components for easy installation:

5585 - Mini-Boiler &

10 kW TS Series

5586 - TS Series, Standard

5578 - 3/4” Pipe

5582 - 1” Pipe

5579 - 1-1/4” Pipe

•

120V, 1/25 HP, maintenance-free wet

rotor

circulator

•

Pump curve example - 5 GPM (19 L)

@ 11 ft. of head (32.9 kPa)

•

120V, 1/6 HP, maintenance-free oil

lubricated

circulator

•

Pump curve example - 10 GPM (37.8 L)

@ 20 ft. of head (50.8 kPa)

•

Two fl anges, with isolation valve

Model

Application

Return Gauge

Expansion Tank

Air Vent

EMB-BK

All EMB Series

2.1 gal. (7.9 L), 40,000 Btu/h

Basic fl oat type

EMB-PK

All EMB Series

2.1 gal. (7.9 L), 40,000 Btu/h

Enhanced air separator, EAS

EB-PK-M

EB-MS, -MA, -MO Series

4.5 gal. (17 L), 135,000 Btu/h

Enhanced air separator, EAS

EB-BK-TS

EB-S, -WA, -WO Series

4.5 gal. (17 L), 135,000 Btu/h

Basic fl oat type

EB-PK-TS

EB-S, -WA, -WO Series

4.5 gal. (17 L), 135,000 Btu/h

Enhanced air separator, EAS

TWO SUPPLY WATER TEMPERATURE REQUIREMENT

INSTALLATION PLUMBING KITS

CIRCULATING PUMPS