Back

of

Pot

Back

of

Pot

Back

of

Pot

Back

of

Pot

Back

of

Pot

Back

of

Pot

Back

of

Pot

Back

of

Pot

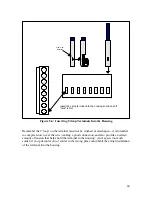

R1

Stage 1

50K Linear

R2

Stage 2

50K Linear

R3

Stage 3

50K Linear

R4

Stage 4

50K Linear

R5

Stage 5

50K Linear

R6

Stage 6

50K Linear

R7

Stage 7

50K Linear

R8

Stage 8

50K Linear

1 2 3 4 5 6 7 8

P207

Analogue Board J7

Figure 6-7: P207 Programming Pot Connections

Back

of

Pot

Back

of

Pot

Back

of

Pot

Back

of

Pot

Back

of

Pot

Back

of

Pot

Back

of

Pot

Back

of

Pot

R9

Stage 9

50K Linear

R10

Stage 10

50K Linear

R11

Stage 11

50K Linear

R12

Stage 12

50K Linear

R13

Stage 13

50K Linear

R14

Stage 14

50K Linear

R15

Stage 15

50K Linear

R16

Stage 16

50K Linear

1 2 3 4 5 6 7 8

P208

Analogue Board J8

Figure 6-8: P208 Programming Pot Connections

58