16

Installation manual

5.5

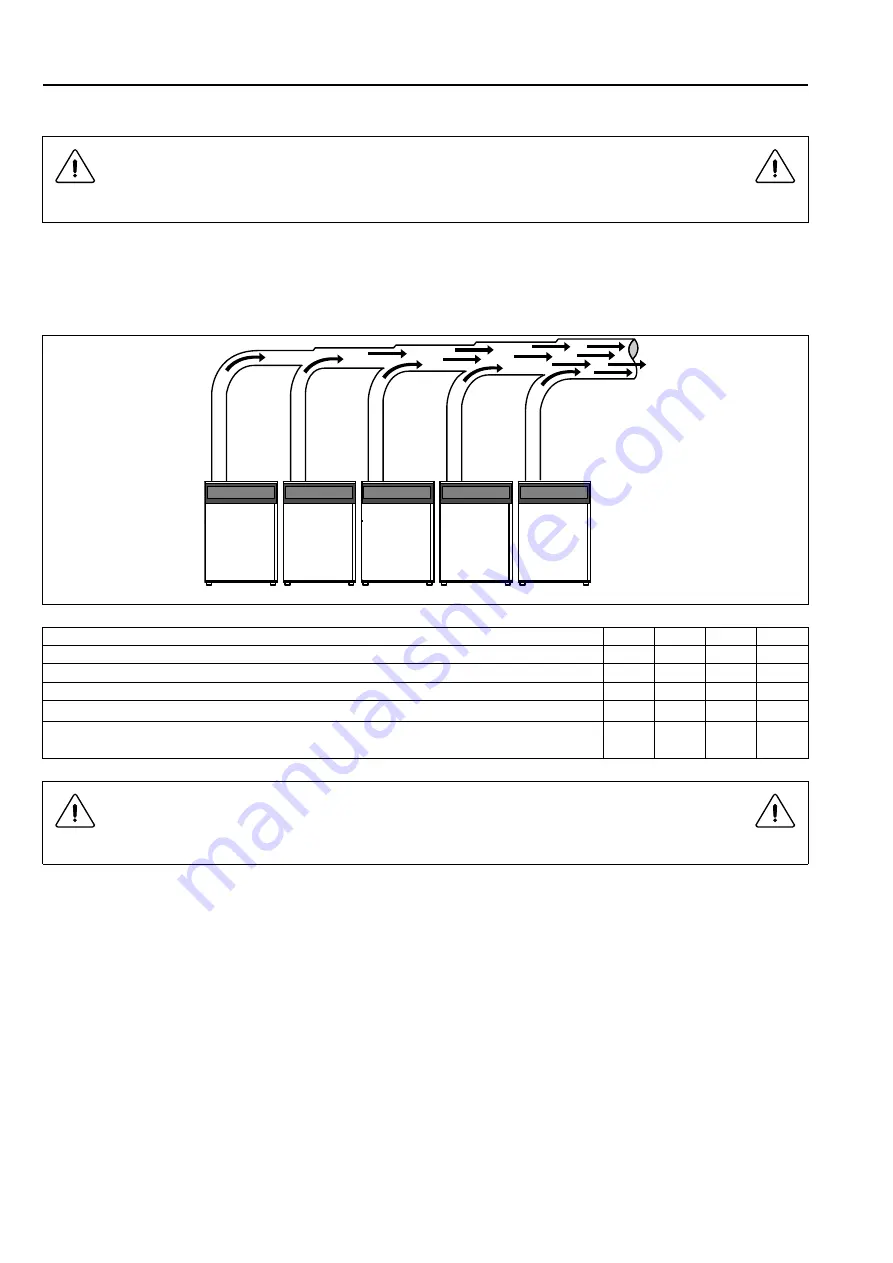

Shared exhaust duct

It is recommended that each machine is connected to a separate exhaust duct.

When several machines shall use the same exhaust duct the exhaust duct must increase after each machine. The

recommended diameter increase progression is the one in the table.

If several machines are installed on the same exhaust pipe, it is recommended to adjust the airflow on the machines

when all machines are started and running a program with no heat.

Please consider that unnecessarily large ducts create issues with the draught.

fig.W00198

Number of machines

1

2

3

4

Exhaust m

3

/h

140

280

420

560

⌀

mm

100

100

100

100

Fresh air inlet cm

2

300

400

600

800

Exhaust duct length 0–6 m

⌀

mm

100

100

160

160

Exhaust duct length 6–50 m

⌀

mm

If the exhaust duct length exceeds 6 m the diameter must be increased.

100

160

200

200

The exhaust duct diameter must not be reduced.

5.6

Exhaust dimensioning

It is important that the machine has correct air volume compared to each machines power.

If the air flow is smaller or larger this will result in a longer drying period.

If the outlet pipe is long or the ventilation is not properly designed we recommend to clean the outlet pipes periodi-

cally. Usually, longer ducts need more frequent cleaning.

The exhaust pipes shall be short in order for the machine to work in the best way.

All cover panels must be mounted in order for the machine to work in the best way.