52

5954 00U 01

GB

ATTENTION:

The warranty does not cover damage caused by the use of deter-

gents and rinse aids not complying with the above characteristics.

- Detergent and rinse aid containers, independent of the oven,

must not be placed

higher than the appliance support surface (for

model 6 GN they must be placed lower than the oven support top).

Attention:

Contact with chemical substances (e.g.

detegent, rinse aid, scale remover, etc.) without

taking adequate safety precautions. Therefore

always refer to the safety cards and labels on the

products used.

To facilitate oven compartment cleaning, remove the rack trolley

guides from the bottom of the oven and open the suction wall.

• To open the oven compartment

suction wall A

(Fig. 2) proceed

as follows:

- switch the oven off and disconnect the power to the appliance;

- undo (1a) screw B2 completely with a screwdriver,

- insert the tip of a screwdriver in slot B and prise (1b) inwards to

open the wall, unhooking it from the pegs B1 at the back.

If required,

completely

remove

suction wall:

- unscrew (2) nut C1 with a hexagon wrench.

- lift (3) the suction wall and remove it (4) from the bottom pin C

of the oven compartment;

- lower (5) the wall to release it from the top pin D and completely

remove it (6).

B2

B

D

C

C1

2

3

4

5

6

A

B2

1b

1a

B1

B1

2

To re

fi

t the wall, repeat the steps in reverse order and retighten

nut C1.

• If present, clean the oven compartment

grease

fi

lter

(not sup-

plied) at least every three cooking cycles.

• If present, clean the

air

fi

lter

(not supplied)

at least once a

month, removing it from under the

control panel

.

1

2

Removal

Air fi lter

Fitting

Non-compliance with the above will result in

fi

lter inef

fi

ciency and

produce anomalous effects in cooking.

• Clean the stainless steel parts every day using lukewarm soapy

water, rinsing with plenty of water and drying thoroughly.

• Do not clean the stainless steel with steel wool, brushes or

scrapers in common steel, as they could deposit ferrous particles

which oxidise, causing rust spots.

• Whenever the appliance is not used for long periods:

- Disconnect the power supply and close the water and gas cocks;

- go over all steel surfaces vigorously with a cloth moistened with

paraf

fi

n oil in order to create a protective

fi

lm;

- Periodically air the premises.

6.2 REPLACING CONSUMABLE COMPONENTS

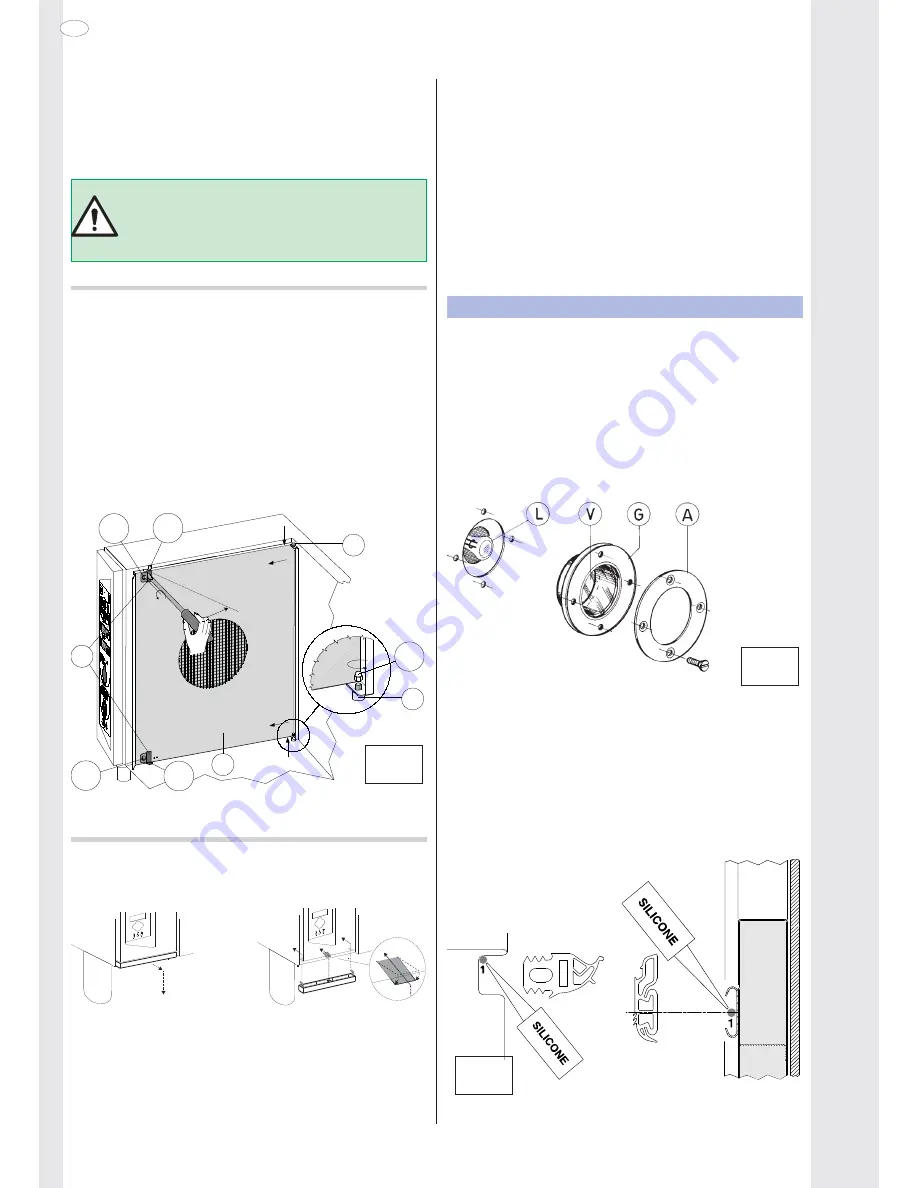

Replacing the oven compartment lamp

(Fig. 3)

To replace the oven compartment lamp, if burnt out, proceed as

follows:

• Disconnect the power to the appliance.

• Undo the 4 screws

fi

xing the light

fi

tting ring nut "A" and remove

the glass "V" together with seal "G".

• Remove the halogen lamp "L" and replace it with another one

having the same characteristics (12V - 10W - 300°C), using a

clean cloth or paper to avoid direct contact with

fi

ngers.

• Re

fi

t the protection glass, correctly inserted inside the seal, in

the lamp compartment and

fi

x the ring nut by retightening the 4

screws, after smearing the seal with food-grade silicone grease.

3

Replacing door seals

(Fig. 4)

NB

: The door seal is a component that can become worn over

time. It is advisable to replace it whenever any hardening or

breakage is noticed.

To replace it, proceed as follows:

• Remove the seal from its seat and clean the latter of any traces

of silicone.

• Apply a bead of silicone sealant at point

1

along the inside pro

fi

le

of the seal seat.

• Insert the new seal along the entire seat.

4

Summary of Contents for 236200

Page 24: ...54 5954 00U 01 GB ...