IIM

MP

PO

OR

RT

TA

AN

NT

T

Incorrect levelling of the appliance can

affect

combustion

and

cause

malfunctioning.

E

E..6

6..4

4

C

Co

on

nn

ne

eccttiio

on

n

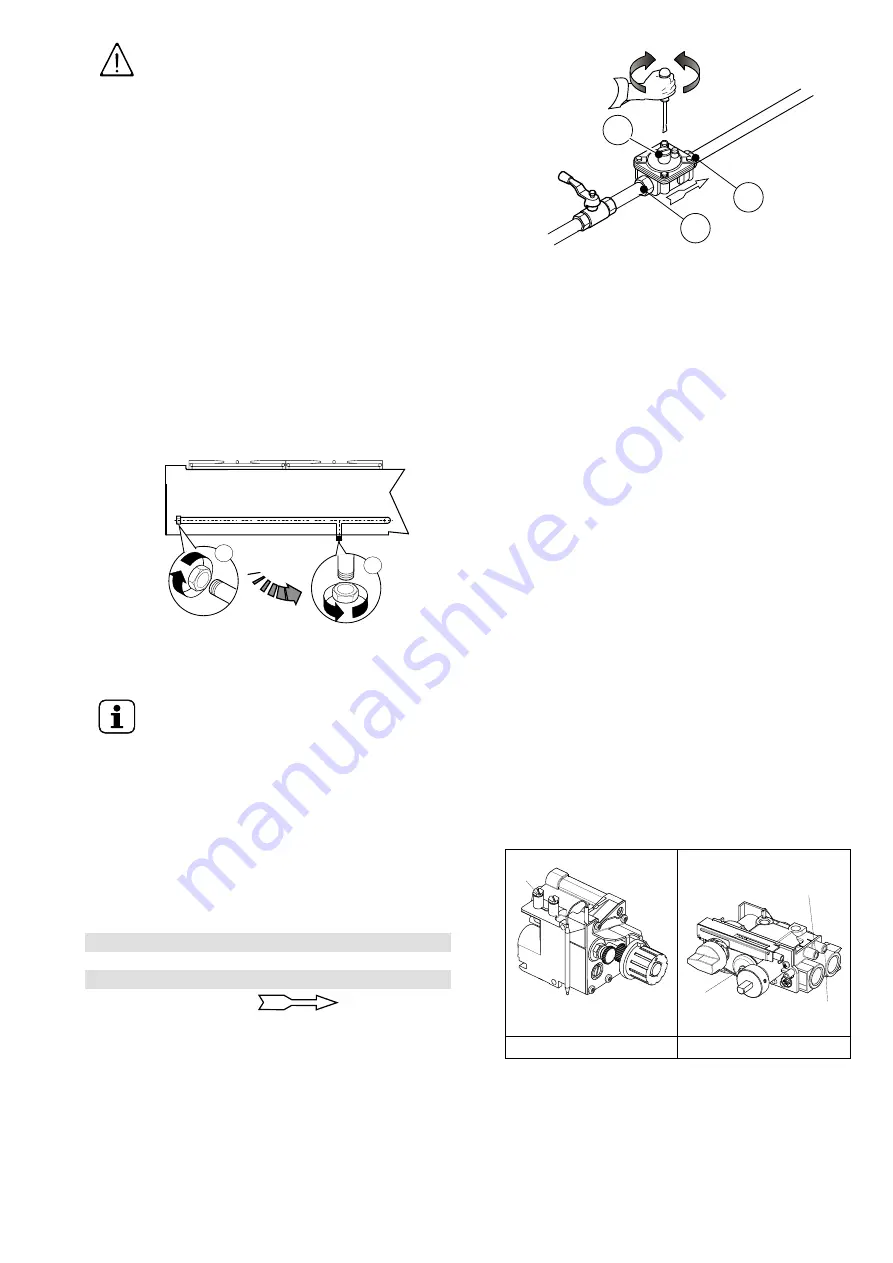

Monoblock models

1. See the installation diagram for the position of the gas

connection on the bottom of the appliance.

2. Remove the plastic cap protection (if present) from the gas

manifold before connecting.

Countertop models

1. See the installation diagram for the position of the gas

connection on the bottom of the appliance.

2. Remove the plastic cap protection (if present) from the gas

manifold before connecting.

3. Countertop models can be connected to the gas supply

also using the rear connection:

a. operate at the back appliance;

b. unscrew the metal closing plug of the rear connection;

c. screw it tightly onto the bottom connection.

After installation, use soapy water to check connections for

leaks.

NOTE!

O

On

nllyy ffo

orr A

Au

ussttrra

alliia

a: The gas connection is male 1/2

BSP.

E

E..6

6..5

5

G

Ga

ass p

prre

essssu

urre

e rre

eg

gu

ulla

atto

orr

The section of the gas supply line must be sufficient to ensure

the gas flow necessary for full operation of all the appliances

connected to the system.

If the gas pressure is higher than that specified or is difficult to

regulate (not stable), install a gas pressure regulator (acces-

sory code 927225) in an easily accessed position ahead of the

appliance.

The pressure regulator should preferably be fitted horizontally,

to ensure the right outlet pressure.

1

connection side gas from mains

2

pressure regulator

3

connection side gas towards the appliance

The arrow on the regulator

indicates the gas

flow direction.

F

Fo

orr A

Au

ussttrra

alliia

a: Adjust the test point pressure with burners

operating at maximum setting (see Appendix, Table “B“)

E

E..6

6..6

6

C

Co

on

nvve

errssiio

on

n tto

o a

an

no

otth

he

err ttyyp

pe

e o

off g

ga

ass

Nozzle Table “B“ (see Appendix) gives the type of nozzles to

be used when replacing those installed by the manufacturer

(the number is engraved on the nozzle body).

At the end of the procedure, carry out the following check-list:

1. burner nozzle/s replacement

2. correct adjustment of primary air supply to burner/s

3. pilot nozzle/s replacement

4. minimum flame screw/s replacement

5. correct adjustment pilot/s if necessary

6. correct adjustment of supply pressure (see technical data/

gas nozzles table)

7. apply sticker (supplied) with data of new gas type used

E

E..7

7

G

Ga

ass a

ap

pp

plliia

an

ncce

ess rre

eg

gu

ulla

attiio

on

nss

E

E..7

7..1

1

S

Su

up

pp

pllyy p

prre

essssu

urre

e cch

he

ecckk ((a

allll vve

errssiio

on

nss))

Make sure the appliance is suitable for the type of gas

available, according to that given on the dataplate (otherwise,

follow the instructions given in E.6.6

type of gas paragraph of this section).

The supply pressure must be measured with the appliance

operating, using a pressure gauge (min. 0.1 mbar).

1. Remove the control panel.

2. Remove retaining screw “N“ from the pressure point (see

following figures);

3. Connect the manometer “O“;

4. Compare the value read on the manometer with that given

in Table “B“ (see Appendix).

If the manometer gives a reading outside the range of

values in Table “B“ (see Appendix), do not switch the

appliance on, consult the gas company.

(7L fryers)

(15L fryers)

1

2

3

3

1

1

2

2

N

N

D

B

19