ENGLI

S

H

33

H

GENERAL SAFETY RULES

H1

Introduction

The machines are provided with electric and/or mechan-

ical safety devices for protecting workers and the

machine itself. Therefore the user must not remove or

tamper with such devices.

The Manufacturer declines any liability for damage due

to tampering or their non-use.

H1.1

Protection devices installed on the machine

H1.1.1

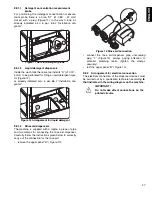

Guards

The guards on the machine are:

-

fixed guards (e.g. casings, covers, side panelling,

etc.), fixed to the machine and/or frame with screws

or quick-release couplings that can only be removed

or opened with tools;

-

interlocked movable guards (front panels) for access

to inside the machine;

-

access doors to the machine’s electrical equipment,

made from hinged panels openable with tools. The

door must not be opened during machine movement,

if inside the door there is equipment that is hazardous

when live or under pressure.

H1.1.2

Safety devices

The machine has:

-

a yellow/red main switch that acts as an emergency

switch;

-

interlocks on the front panels giving access to inside

the machine;

-

emergency stop push buttons and stops must be

installed on the rack handling tables in case the racks

exceed their travel.

H1.2

Safety signs to be displayed on the machine

IMPORTANT!

Several illustrations in the manual repre-

sent the machine, or parts of it, without

guards or with guards removed. This is

purely for explanatory requirements.

Never operate the machine without the

guards or with the safety devices deacti-

vated.

PROHIBITION

MEANING

Do not oil, lubricate, repair and

adjust moving parts.

Do not remove the safety

devices.

Do not use water to extinguish

fires (shown on electrical parts).

DANGER

MEANING

DANGER OF CRUSHING HANDS

DANGER OF BURNS

DANGER OF ELECTROCUTION

(shown on electrical parts with

indication of voltage).

WARNING!

Do not remove, tamper with or make the

labels on the machine illegible.

ref. A

ref. B

CAUTION

THI

S

DI

S

HWA

S

HER HA

S

MORE THAN ONE POWER-

S

UPPLY

CONNECTION POINT. DI

S

CONNECT ALL POWER

S

UPPLIE

S

BEFORE

S

ERVICING.

Doc.No.: 5956.613.00

MINIMUM WA

S

H TEMPERATURE 160°F (71°C)

MINIMUM PUMPED RIN

S

E TEMPERATURE 1

8

0°F (

8

2°C)

MINIMUM

SANITIZING RINSE TEMPERATURE 180 °F (82 °C)

MAX. CONVEYOR

S

PEED 5.4

8

FT./MIN (1.67 M/MIN)

Doc.No.: 5956.5

8

2.00

WARNING

THERE ARE MOVING PART

S

.

THERE I

S

THE PO

SS

IBILITY OF

S

PRAYING

AND

S

PLA

S

HING OF HOT WATER.

Doc.No.: 5956.5

8

2.00