11

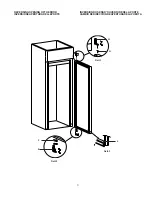

WARNING:

during handling do not push or pull the unit: it may tip over or

be

damaged.

B.1.2.2 Disposing of the packing

Packing materials should be disposed of accordance with the

binding laws in the country where the appliance is to be used.

Recyclable plastic parts are marked as follows:

polythene:

outer wrapping, instructions booklet

bag

PE

polypropylene:

straps

PP

polystyrene foam:

protective surround elements

PS

pressed board:

protective surround elements

B.2.1 MATERIALS AND FLUIDS USED

All areas designed to come into contact with food are in steel

or covered in non-toxic plastic material. An HFC refrigerant, in

compliance with current legal standards, is used in the refrig-

erating units. The type of refrigerant gas used is stated on the

data plate.

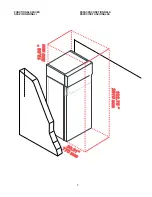

B.2.2 DIMENSIONS, PERFORMANCE AND CONSUMPTION

External dimensions:

- Width

29.53”

750mm

- Depth with door closed

38.38”

975mm

- Depth with door open

65.35”

1660mm

- Height

83.07”

2110mm

Chamber dimensions:

- Width

24.80”

630mm

- Depth

34.25”

870mm

- Height

66.81”

1697mm

Gross capacity

245.68 gal

930 Iiters

Power supply

120V 1Ph 60Hz

Internal temp. range

+32°F/+50°F

0°C/+10°C

Max. ambient temp.

+109.4°F

+43°C

Current input (°)

8 A

Refrigerant charge R134a

0.595lbs

270 gr

Refrigerant capacity (R134a) (¹)

526 W

Refrigerant capacity (R134a) (²)

1137 W

No. and type of defrostings (*)

min 1 each 24h x max 30‘

(°) At room temperature 104°F/40°C.

(¹) At room temperature 89.6°F/32°C, condensation

temperature 131°F/+55°C and evaporation temperature

14°F/-10°C.

(²) ASHRAE PERFORMANCE ambient temperature 89.6°F/

+32°C, condensation temperature 131°F/+55°C and

evaporation temperature 44.96°F/+7.2°C.

(*) Auto (by electronic board)

B.2.3 PHYSICAL SAFETY FEATURES, HAZARDS

The appliance has no sharp or projecting parts.

The guards for the mobile and live parts are bolted on to the

cabinet to prevent accidental access.

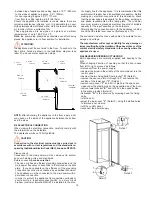

B.2.4 POSITIONING

Install the equipment, taking all the safety precautions

required for this type of operation, also respecting

the relevant fire-prevention instructions.

Place the appliance in a ventilated room and away

from heat sources such as radiators or air-

conditioning systems, in order to allow the cooling

of the refrigerating unit components.

Never cover the condenser, not even temporarily, as

this may jeopardise the operation of both the

condenser and the appliance.

Make sure to position the appliance taking into consideration

the space needed for door opening.

Pay particular attention to levelling of the floor on which the

appliance stands, in order to ensure its optimal operation.

IMPORTANT:

level the appliance, otherwise its operation could be compro-

mised. The appliance must be sealed to the floor with silicone.

ADVICE:

the part of the floor on which the cabinet is placed should be

physically insulated from the rest of the supporting surface

by means of suitable thermal insulating material, and when

possible, by means of a heat barrier.

For optimum appliance operation, please follow recommended

spacing for equipment:

19.68 " 1

9

.6

8

"

500 mm5

0

0

m

m

30.31"

30

.31"

770 mm

770

mm

102.75 " 1

0

2

.7

5

"

2610 mm2

6

1

0

m

m

B.2 TECHNICAL DATA