7

TABLE OF CONTENTS

USA

SAFETY INSTRUCTIONS ......................................................... Page 9

A.1 GENERAL INFORMATION........................................................ Page 10

A.1.1

Foreword ..................................................................................................................... Page 10

A.1.2

Intended use and limitations ...................................................................................... Page 10

A.1.3

Testing ......................................................................................................................... Page 10

A.1.4

General safety rules .................................................................................................... Page 10

A.1.5

Customer’s responsibilities ....................................................................................... Page 10

A.1.6

Data plate position ...................................................................................................... Page 10

A.1.7

Physical safety features, hazards ............................................................................... Page 10

B.1 INSTALLATION ......................................................................... Page 10

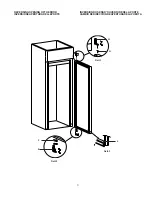

B.1.1

Immediate inspect for shipping damage ................................................................... Page 10

B.1.2

Removing the packaging ............................................................................................ Page 10

B.1.2.1 Removing the packaging and handling ...................................................................... Page 10

B.1.2.2 Disposing of the packing ............................................................................................ Page 11

B.2 TECHNICAL DATA .................................................................... Page 11

B.2.1

Materials and fluids used ............................................................................................ Page 11

B.2.2

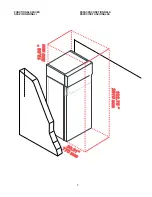

Dimensions, performance and consumption ............................................................ Page 11

B.2.3

Physical safety features, hazards ............................................................................... Page 11

B.2.4

Positioning .................................................................................................................. Page 11

B.2.5

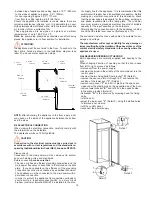

Electrical connection ................................................................................................... Page 12

B.2.6

Reversing opening of the door ................................................................................... Page 12

B.2.7

Checking hinges ......................................................................................................... Page 13

C.1 OPERATIONS and USER INSTRUCTIONS ............................. Page 13

C.1.1 Control panel ............................................................................................................... Page 13

C.1.2 Initial switch-on and temperature adjustment ............................................................ Page 13

C.1.3 Storage using catergories button ................................................................................ Page 14

C.1.4 “High humidity ON/OFF” button ................................................................................... Page 14

C.1.5 Loading the product .................................................................................................... Page 15