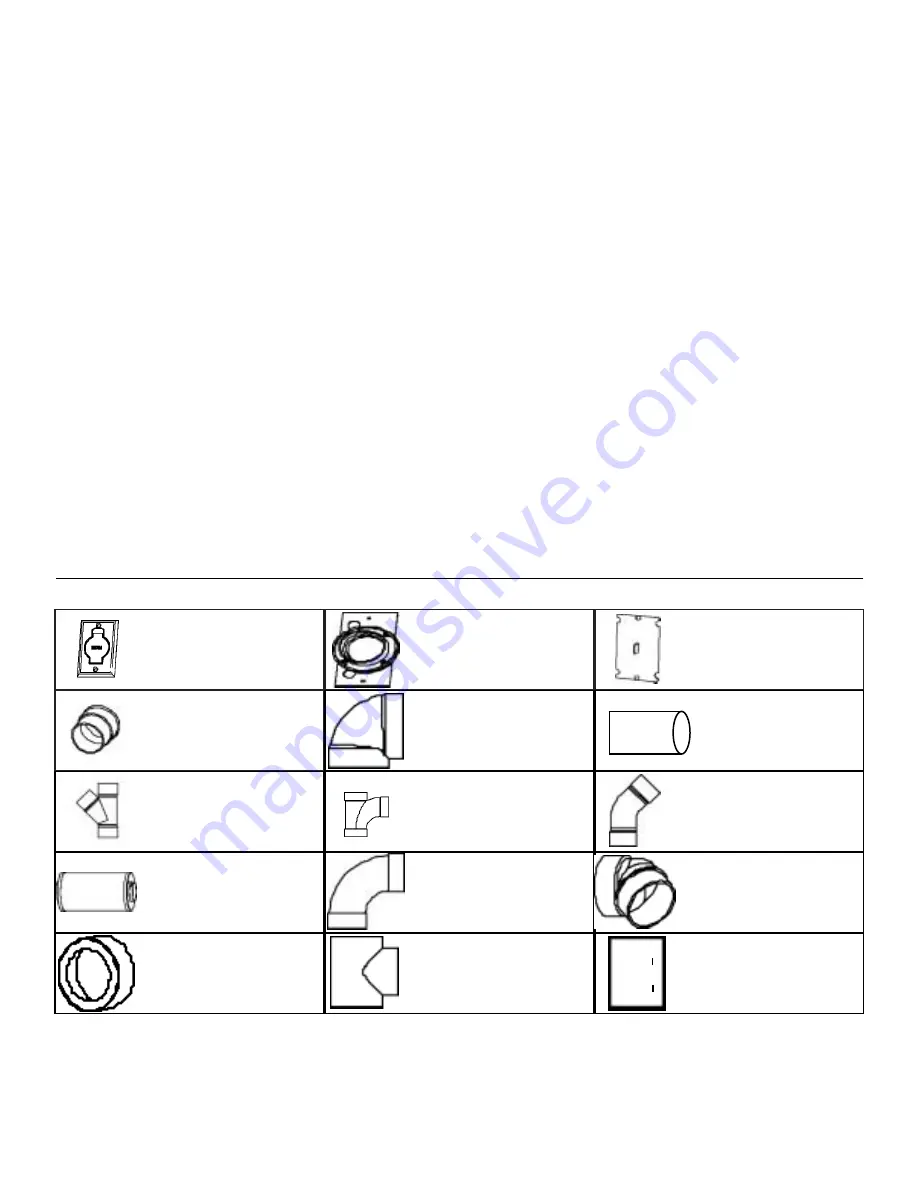

INLET VALVE EXTENSION

(for thick walls metal)

PLASTIC PLASTER

GUARD

(for new structure)

AUTOMATIC INLET VALVE

(plastic or optional metal)

ADAPTER & BRACKET

ASSEMBLY

(new or old structure)

3.

Use this vacuum only for its intended use as described in this manual. (Use of attachments not recommended

by the manufacturer may cause fire, electric shock, or injury.)

4.

Never operate this vacuum if it has a damaged cord or plug, if it is not working properly, if it has been dropped,

or damaged. Return to service center or have service person examine and repair.

5.

Do not pull or carry this power unit by supply cord, use cord as a handle, close a door on cord, or pull cord

around sharp edges or corners.

6.

Never disconnect plug by pulling on cord. To disconnect from outlet, grasp the plug, not the cord.

7

Do not put any object into openings. Do not use with any opening blocked; keep free of dust, lint, hair, and

anything that may reduce air flow.

8.

Keep hair, face, fingers, and loose clothing away from any openings.

9.

Do not pick up cigarettes, live hot ashes, matches or similar materials.

10. Never operate vacuum without dust bag and/or filter in place.

11. To disconnect, turn all controls to the OFF position; then remove plug from outlet.

12. Never handle plug, cord, or power unit with wet hands.

13. Electric shock could occur if used on wet surfaces.

14. Use extra care when cleaning on stairs.

15. Do not use to pick up flammable or combustible liquids such as gasoline or use in areas where they may be

present.

16. For a grounded appliance: “Connect to a properly grounded outlet only. See grounding instructions.”

SAVE THESE INSTRUCTIONS

QUICK CHECK TABLE OF COMMON AND SPECIAL USE PARTS

90 DEGREE DUAL ELBOW

(Use w/above assembly or

as first bend in line. Never

elsewhere.)

COUPLINGS

(joins PVC tubing)

45 DEGREE Y

90 DEGREE SWEEP

ELBOW

45 DEGREE ELBOW

PLASTIC EXHAUST MUF-

FLER

90 DEGREE SWEEP

ELBOW

45 DEGREE ELBOW

with extension

ADAPTER, REDUCER

BUSHING

(for pipe to floor

mounted inlet valve)

T-ADAPTER

(for two story) (for two inlets in

same wall) Use only

w/adapter and bracket

assemblies.

NAIL GUARD