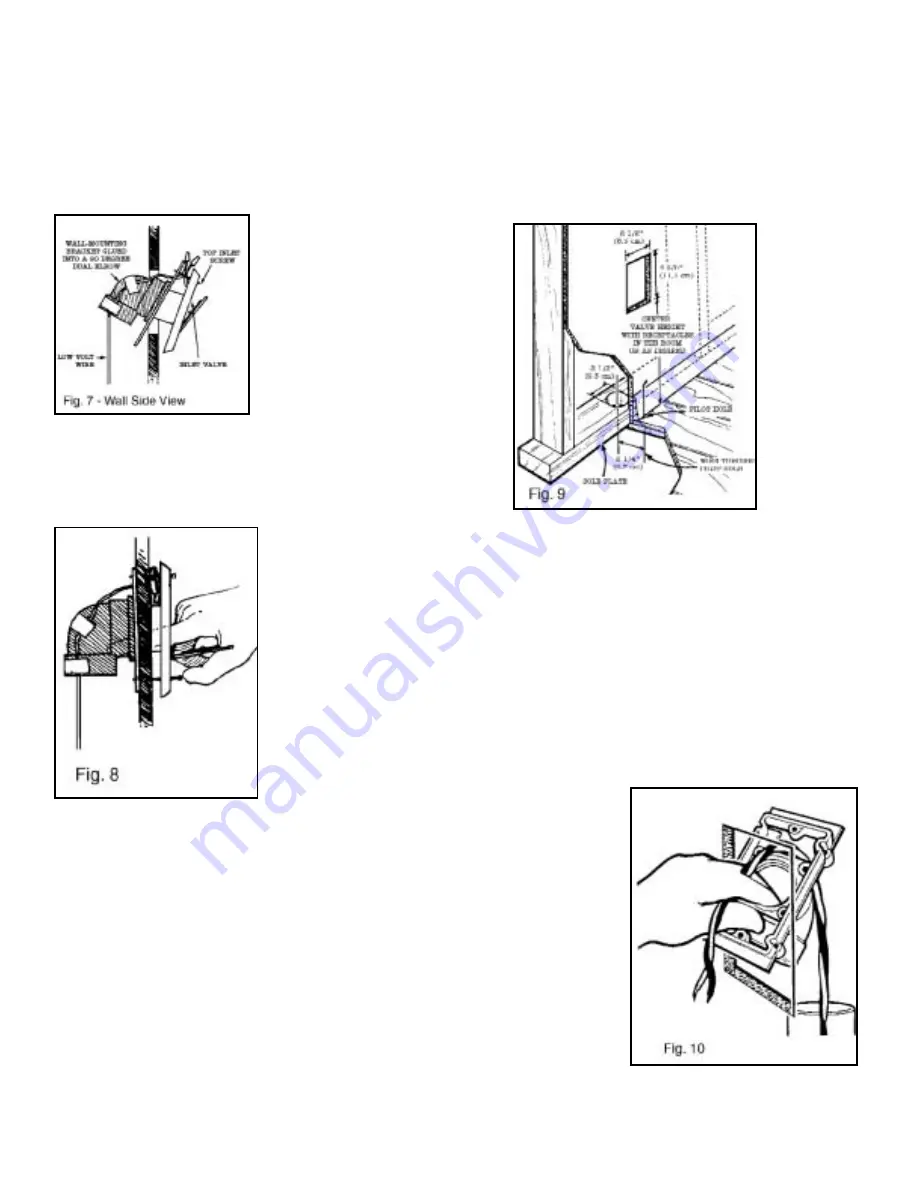

insert assembled 90 degree dual elbow and

wall-bracket assembly through wall cutout hole

as illustrated (Fig. 7).

Once metal mount-

ing bracket is com-

pletely inside wall

cavity, slide the

entire assembly

upwards so metal

plate is flush with

inner wall surface

and inlet valve is

flush with outer wall

surface. You can

insert index finger

through inlet valve opening and gently squeeze

inlet valve stem further into inner wall assembly

(Fig. 8).

NOTE: Mount inlet

valve so lid pulls

down to open.

Now, insert and

partially tighten

bottom\Inlet valve

screw. Tuck low-

voltage wires and

connectors under

sides of wall inlet

valve. Adjust inlet

valve for perfect

vertical alignment

and tighten both

inlet valve mounting screws. Be sure the inlet

valve lid operates freely. Apply glue to an ade-

quate length of tubing and aim it upwards

through the hole and into the 90 degree dual

elbow fitting on the back of the mounting plate.

Join this branch line to the trunk line using a 90

degree sweep tee.

If the inlet valve is to be serviced from the attic,

shorter pieces of tubing joined by couplings

may be required due to overhead space restric-

tions. Precut these pieces and work quickly to

prevent the cement on the end of the tubing

from drying before it reaches the fitting at the

valve below.

c) Using PLASTIC Stud-Mounting

Bracket

Having determined the location is suitable, cut

a 2- 1/2" (6.35cm) x 4-3/8" (11cm) hole in the

wall at the

desired inlet

valve loca-

tion (See Fig.

9).

Now cut or

break off

“new con-

s t r u c t i o n ”

section from

plastic wall

m o u n t i n g

b r a c k e t .

Tape low-

voltage wire

to the end of a sufficiently long piece of tubing

and pass it up from beneath. If the trunk line is

in the attic, tie a weight to the end of the low-

voltage wire and lower it through the opening.

Remove the wire and pass it through the upper

hole in the trimmed mounting plate. Bare an

inch of both wire leads and wrap them around

the lugs on the back of the valve in a clockwise

direction. Tighten the lugs with a Phillips screw-

driver.

Apply cement to the flange on the back of the

mounting plate

and attach a

90 degree

dual elbow fit-

ting oriented in

the appropri-

ate direction.

Tilt the mount-

ing plate for-

ward and

angle it into

the hole in the

wall. Center

the mounting

plate in the

hole and pull

outward (See Fig. 10).