Electrolux air-o-steam - level B

Combi LW 6 GN 1/1-electric

Internet: http://www.electrolux.com/foodservice

ECAB010

2011-02-22

Subject to change without notice

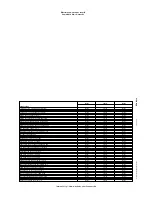

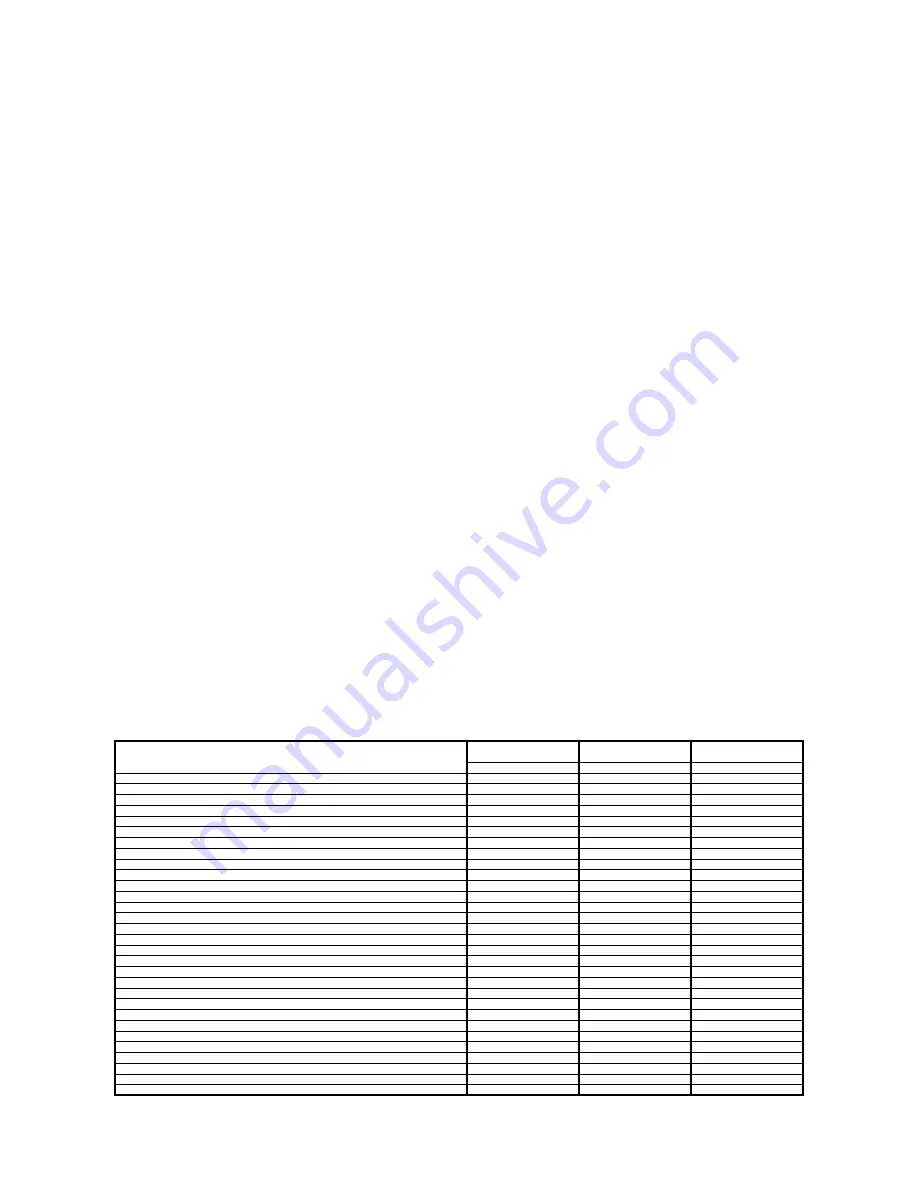

Supply voltage

400 V, 3N, 50/60

400 V, 3N, 50/60

230 V, 3, 50/60

Net weight - kg.

132

132

132

auxiliary

0.5

0.5

0.5

electric

10.1

10.1

10.1

cooking chamber

9.6

9.6

9.6

boiler

9

9

9

Power - kW

height

486

486

486

depth

715

715

715

width

460

460

460

Internal dimensions - mm

height

808

808

808

depth

915

915

915

width

898

898

898

External dimensions - mm

Automatic cleaning system

●

●

●

Meat probe

●

●

●

Two-speed fan

●

●

●

Low temp steaming

●

●

●

Regeneration

●

●

●

Convection/steaming

●

●

●

Steaming

●

●

●

Convection

●

●

●

combi

250

250

250

steam

130

130

130

air-convection

300

300

300

Cooking cycles - °C

Runners pitch - mm

65

80

65

Number of grids

6

5

6

Power supply

Electric

Electric

Electric

TECHNICAL DATA

AOS061EBA2

268200

AOS061EBH2

268210

AOS061EBN2

268220

PERFORMANCE

• By-pass technology: controls the

humidity degree of the oven

atmosphere in combi and

regeneration cycles. It prevents

water and energy waste.

• air-o-flow: blows fresh air from

outside through the bi-functional

fan, which pulls the air in from the

backside of the oven after it is

pre-heated, thus guaranteeing an

even cooking process.

• Single-sensor food probe.

CONSTRUCTION

• Stainless steel 304 throughout,

with seamless joints in the cooking

cell.

• Double thermo-glazed door

equipped with drip pans to catch

condensate and prevent slippery

floor for maximum security and

four holding positions allowing

easier loading and unloading.

• Halogen lighting in the cooking

cell.

• Access to main components

from the front panel.

• Automatic scale diagnosis

system in the steam generator to

detect the presence of scale

build-up.

• IPX5 water protection.

• air-o-steam ovens meet IMQ

safety requirements.