38

GB

5938 033 01

Note:

Press the button again to switch from the PROBE function to the

TIME function: the relative LED on the DISPLAY will light up.

4)

Start the cycle

. Press the

Cooking Start/Stop

button.

5)

Stop the cycle

. When the required product core temperature

reaches the set temperature the oven stops automatically as

described in heading

4.3.7 STOPPING THE COOKING CYCLE

and elapsed cooking cycle time is shown on the large DISPLAY.

6)

Deactivating core probe mode.

(Possible only with no cooking

cycle active). Set a cooking time on Timer

TM

.

Probe cooking mode is also deactivated when the oven is

switched off.

At the end of the cycle total cooking cycle TIME is shown on the

large DISPLAY.

4.3.5

SETTING COOKING HUMIDITY

LEVEL

A

and

C

ONLY

(Only in

CONVECTION

,

MIXED

and

REGENERATION

cooking modes)

Attention

When switching on the oven after several hours in which it

has not been used, wait about 20 seconds (LAMBDA probe

stabilisation time) to ensure accurate reading of the HUMIDITY

value.

Note

To set humidity in AIR-CONVECTION cooking mode press the

relative cycle selection button twice.

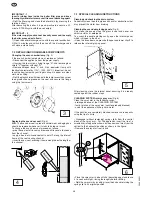

After selecting AIR-CONVECTION or MIXED cooking mode the large

DISPLAY (LEVEL

A

only) will show OVEN CHAMBER HUMIDITY and

the small display (LEVEL

A

1%...100% and

C

1

/10

...10

/10

) will show the

humidity to be SET (flashes for 5 seconds).

E.g.: 60 %

OVEN CHAMBER

HUMIDITY

E.g.: 80 %

COOKING

HUMIDITY

Turn the knob clockwise (to increase the value) or counter clockwise

(to decrease the value) to set the desired COOKING HUMIDITY on

the small DISPLAY.

After 5 seconds the COOKING HUMIDITY value stops flashing to

indicate that it has been SET.

4.3.6 STARTING THE COOKING CYCLE

- make sure the oven door is closed;

- press the luminous start cooking button, which will light up

(light FLASHING), for COMPARTMENT PREHEATING;

PrEH

Start COMPARTMENT PREHEATING

(light FLASHING)

The displays will show:

-

HU

humidity inside the compartment;

-

TS

automatic compartment preheating (PrEH). To skip preheat-

ing press the START button again.

-

TM

time remaining for end of cooking /

PRB

core probe tem-

perature.

Note:

In TIMED cooking, during preheating the set cooking

time remains unchanged (COUNT-DOWN not activated).

At the end of preheating the message

LOAD

appears on the

display

TS

:

- open the oven door and load the food.

- close the door, and the message

Strt

(START) appears on the

display

TS

- press the start cooking luminous button again; it will light up

(FIXED light);

Start COOKING CYCLE

(light FIXED)

(COUNT-DOWN activated)

Note

:

- No cooking cycle will be available (steam, mixed, air-convection

or regeneration) until the boiler is ready (boiler LED switches off

- see heading 4.1).

During this interval the time count will not start and the

Start

cooking

button will flash (the same will occur when the oven door

is opened).

Important

! Risk of burns.

Open the door with due care when the appliance is hot.

4.3.7 STOPPING THE COOKING CYCLE

When the set time has elapsed the cooking cycle will stop

automatically and the appliance's audible alarm will emit a

continuous beep.

Open the door and remove the product.

Important

! Risk of burns.

Open the door with due care when the appliance is hot.

Note

:

- The audible alarm can be muted by performing any operation

on the control panel or by opening the door.

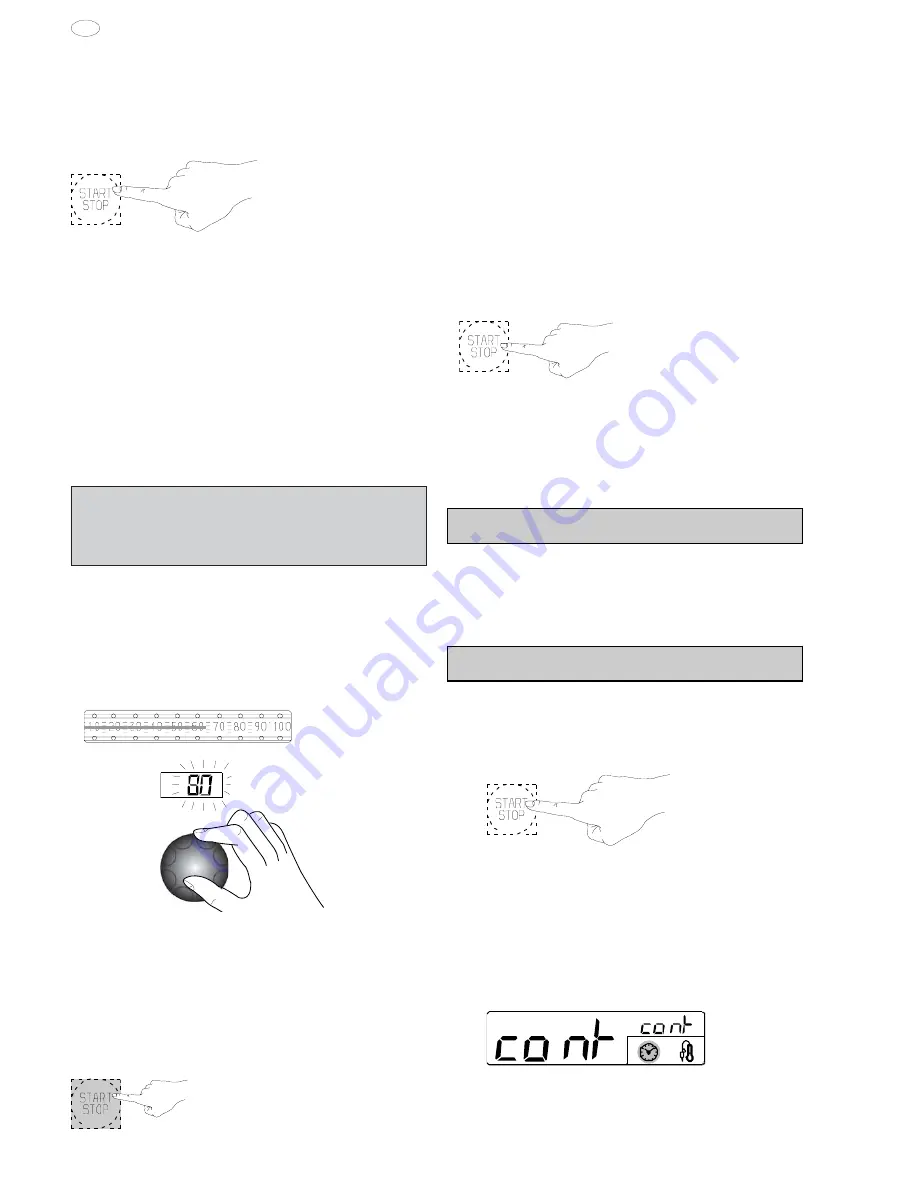

To stop the cooking cycle

manually

press the

cycle Start/Stop

button and keep it pressed for

two

seconds.

If this button is pressed for less than 2 seconds it will produce no

result.

To repeat the last cooking cycle with identical parameters press

the

Start/Stop

button again.

4.3.8 MANUAL CYCLE (CONTINUOUS COOKING)

Manual cooking cycles can be set by excluding the timer. Follow

the instructions in heading 4.3.2 SETTING THE COOKING TIME

until the display shows the word "

cont

", i.e.

continuous

cooking

mode.

In this case the cooking cycle must be stopped manually by

holding down the

Start/Stop

button for two seconds or by switching

off the oven.