28

GB

5938 033 01

Noise emission data:

Noise emissions generated by the appli-

ances described in this booklet do not exceed 70 dB (A).

*

Your appliance model is indicated in the box marked

PNC

on

the Identification dataplate affixed to the bottom left hand side of

the oven.

^ FUNCTIONAL LEVEL (C = Convect, Convection)

.

I. MAIN FEATURES

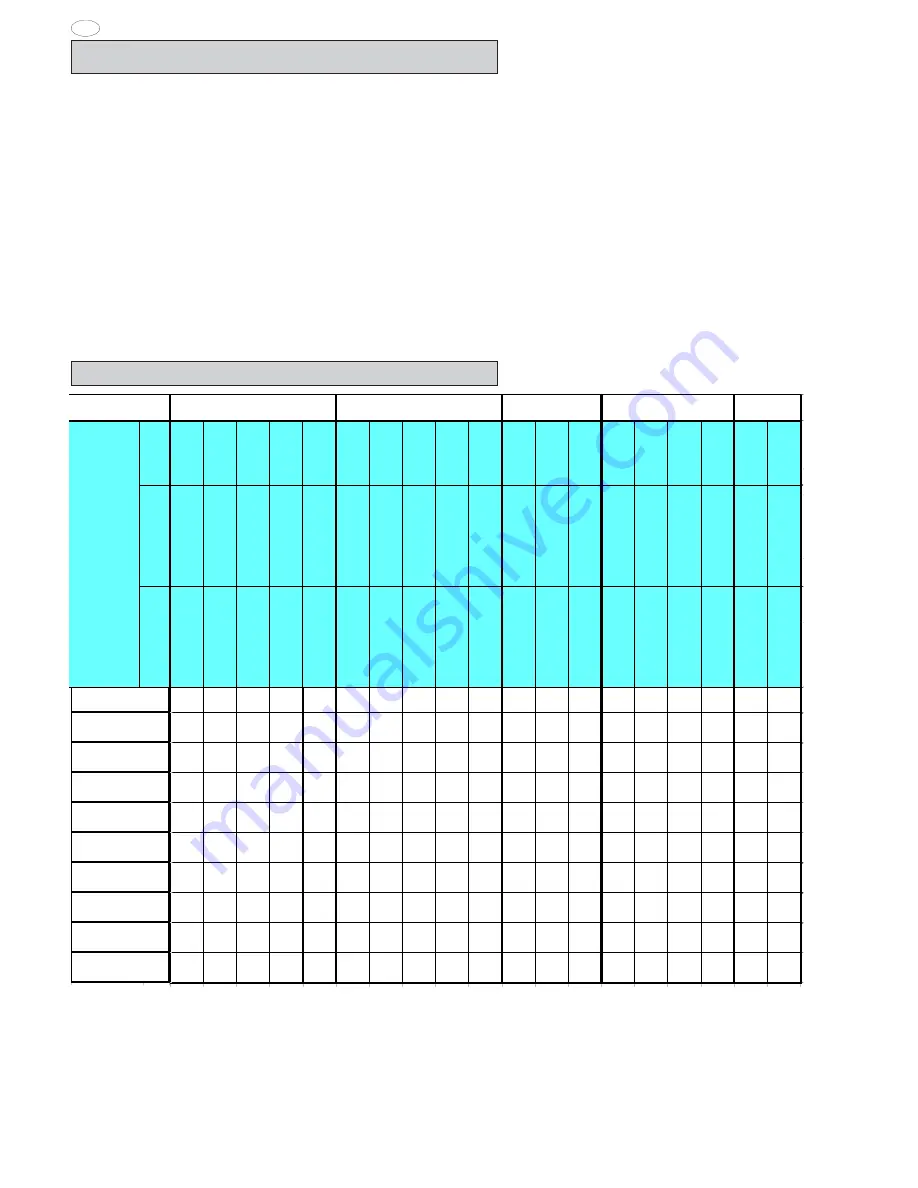

2. TABLE 1: TECHNICAL DATA

1. DESCRIPTION OF APPLIANCE

This booklet describes a number of appliance models.

For more detailed information about the model in your possession,

refer to

"Technical Data"

table 1.

The appliance has the following features:

• Digital temperature indicator.

• Thermostatic probe for measuring the core temperature of pro-

ducts (core temperature probe).

• Continuous monitoring of cooking parameters throughout the

entire cooking cycle.

• Periodic draining and automatic washing of the boiler to prevent

the build-up of lime-scale (only available on certain models).

• Boiler lime-scale level indicator (see corresponding

paragraph)(only available on certain models).

• Oven chamber automatic fast steam drain device for gratins.

• Air-break anti-backup drain device to prevent backflows from the

drainage system from entering the oven (only available on certain

models).

• Oven chamber lighting.

• Double-action door opening

safety

mechanism designed to

protect the user from scalding steam (only available on certain

models).

• Double-glazed oven door for reduced heat dispersion into the

kitchen and low temperatures on the exterior of the oven.

• Daily oven chamber cleaning cycle (CLEANING SYSTEM)(only

available on certain models).

• Self-diagnostics system indicating oven faults using error codes

(see

"Information and error codes "

).

267000

267010

237000

237010

647000

647070

267020

237020

267030

267002

267012

237002

237012

647002

647072

267022

237022

267032

267003

237003

647003

267063

267033

237033

267004

267014

237004

237014

647004

647074

267024

237024

267005

237005

647005

268000

268010

238000

238010

648000

648070

268020

238020

268030

268002

268012

238002

238012

648002

648072

268022

238022

268032

268003

238003

648003

268033

238003

268004

268014

238004

238014

648004

648074

268024

238024

268005

238005

648005

269000

269010

239000

239010

649000

649070

269020

239020

269002

269012

239002

239012

649002

649072

269022

239022

269003

239003

649003

269004

269014

239004

239014

649004

649074

269024

239024

269005

239005

649005

°

**

°

°

**

°

°

**

°

**

°

°

**

°

°

**

°

**

°

°

**

°

**

°

°

**

°

°

**

°

4 0 0

3 N~

4 0 0

3 N~

2 3 0

3 ~

2 3 0

3 ~

2 0 0

3 ~

4 0 0

3 N~

4 0 0

3 N~

2 3 0

3 ~

2 3 0

3 ~

2 0 0

3 ~

4 0 0

3 N~

4 0 0

3 N~

2 0 0

3 ~

4 0 0

3 N~

4 0 0

3 N~

2 3 0

3 ~

2 3 0

3 ~

4 0 0

3 N~

4 0 0

3 N~

5 0 /6 0 5 0 /6 0 5 0 /6 0 5 0 /6 1 5 0 /6 0 5 0 /6 0 5 0 /6 0 5 0 /6 0 5 0 /6 0 5 0 /6 0 5 0 /6 0 5 0 /6 0 5 0 /6 0 5 0 /6 0 5 0 /6 0 5 0 /6 0 5 0 /6 0 5 0 /6 0 5 0 /6 0

1 0 ,1

1 0 ,1

1 0 ,1

1 0 ,1

1 0 ,1

1 7 ,5

1 7 ,5

1 7 ,5

1 7 ,5

1 7 ,5

2 5

2 5

2 5

3 4 ,5

3 4 ,5

3 4 ,5

3 4 ,5

5 0

5 0

2 5

2 5

3 2

3 2

4 0

3 2

3 2

5 0

5 0

6 3

6 3

6 3

1 0 0

6 3

6 3

1 2 5

1 2 5

1 0 0

1 0 0

5 x2 ,5 5 x2 ,5

4 x4

4 x4

4 x4

5 x4

5 x4

4 x1 0 4 x1 0 4 x1 0 5 x1 0 5 x1 0 5 x1 6 5 x1 0 5 x1 0 4 x2 5 4 x2 5 5 x1 6 5 x1 6

0 ,1 9

0 ,1 9

0 ,1 9

0 ,1 9

0 ,1 9

0 ,1 9

0 ,1 9

0 ,1 9

0 ,1 9

0 ,1 9

0 ,7 5

0 ,7 5

0 ,7 5

0 ,3 8

0 ,3 8

0 ,3 8

0 ,3 8

1 ,5

1 ,5

9

9

9

1 7

1 7

1 7

2 4

2 4

2 4

2 0

4 8

9 ,6

9 ,6

9 ,6

9 ,6

9 ,6

1 7

1 7

1 7

1 7

1 7

2 4

2 4

2 4

3 4

3 4

3 4

3 4

4 8

4 8

3 0

3 0

3 0

3 0

3 0

5 0

5 0

5 0

5 0

5 0

1 0 0

1 0 0

1 0 0

1 0 0

1 0 0

1 0 0

1 0 0

2 0 0

2 0 0

2 0 GN 2 /1

6 G N 1 /1

1 0 G N 1 /1

2 0 GN 1 /1

1 0 G N 2 /1

A ^

B ^

C ^

PNC *

GRIDS

CONVECTOR °

BOILER **

POWER SUPPLY

VOLTAGE (VOLT)

FREQUENCY (Hz)

Max. electrical power

input (Kw)

Mains fuses

(3 x 500V)

Power supply cable

cross-section (mm

2

)

Fan motor power rating

(Kw)

Steam unit power rating

(Kw)

Convection unit power

rating (Kw)

Max. food load (kg)

A ^

267000

267010

237000

237010

647000

647070

267020

237020

267030

267072

237002

237012

647002

647072

267022

237022

267032

267003

237003

647003

267063

267033

237033

267004

267014

237004

237014

647004

647074

267024

237024

267005

237005

647005

B ^

238000

238010

268200

268210

268300

238200

238210

648000

648070

268020

238020

268220

238220

268030

268230

238002

238012

268202

268212

268302

238202

238212

648002

648072

268022

238022

268222

238222

268032

268232

268003

238003

268203

238203

268303

648003

268033

268233

238003

238004

238014

268204

268214

268304

238204

238214

648004

648074

268024

238024

268224

238224

268005

238005

268205

268305

238205

648005

C ^

239000

239010

269200

269210

269300

269330

239200

239210

649000

649070

269020

239020

269220

239220

239002

239012

269202

269212

269302

269332

239202

239212

649002

649072

269022

239022

269222

239222

269003

239003

269203

269303

239203

649003

269204

269214

269304

239204

239214

649004

649074

269024

239024

269224

239224

269005

239005

269205

269305

239205

649005

20 GN 2/1

n ° GR IGL IE

6GN 1/1

10GN 1/1

20GN 1/1

10 GN 2 /1

P N C *