SOI 02.10 FV

127/142

599 70 59-01

3.5 -

REMOVING THE WATER FILLER DRAWER AND CONTROL

COMPONENTS

To remove the water filler drawer assembly:

1 - Remove the top oven cover panel.

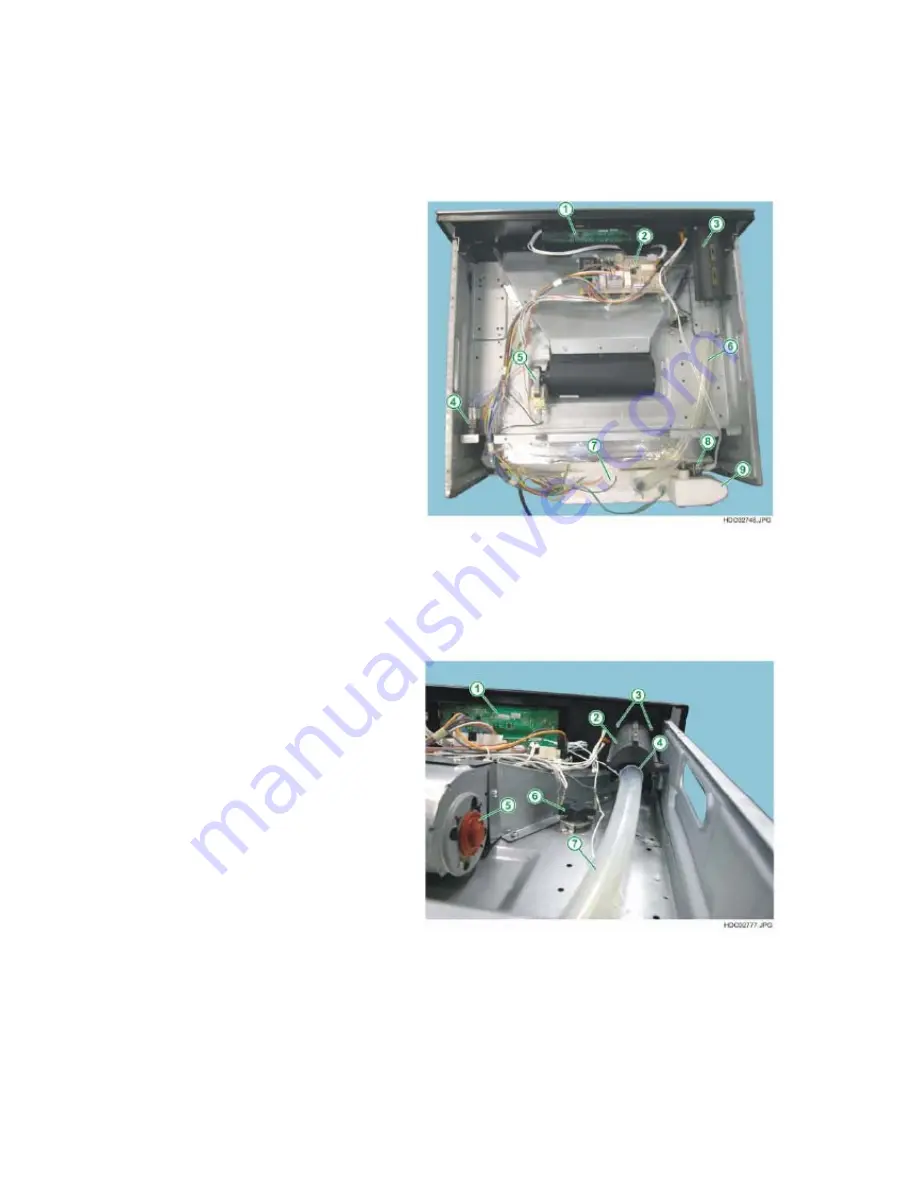

Fig.

263

1 - CONTROL UNIT - KRONOS

2 - POWER BOARD OVC1000

3 - WATER FILLER DRAWER

4 - STEAM GENERATOR

CONTROL RELAY

5 - TANGENTIAL COOLING FAN

6 - WATER FILL PIPE

7 - WATER TANK

8 - TEMPERATURE SENSOR

9 - EXPANSION CHAMBER

2 - Release the water fill pipe retainer clamp and slide the pipe off (see Fig. 264).

3 - Unscrew the water filler drawer assembly fixing screws (see Fig. 264).

4 - Extract the water filler drawer assembly from inside the oven.

Fig.

264

1 - CONTROL UNIT - KRONOS

2 - WATER FILLER DRAWER

3 - FIXING SCREWS - DRAWER

4 - RETAINER CLAMP

- WATER FILL PIPE

5 - TANGENTIAL FAN

6 - SAFETY THERMOSTAT

7 - WATER FILL PIPE