13

Problem

Cause

Correction

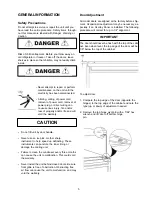

7. Excessive frost build-up.

Cause

8. Noisy.

Cause

9. Fresh food temperature too

cold.

Cause

a. Door gasket not sealing

properly.

b. Door out of alignment.

c. Water soaked cabinet

insulation.

d. Light stays on when door is

closed.

a. Copper refrigeration tube

touching cabinet.

b. Fan blade touching shroud.

c. Fan blade obstruction (wiring,

foam insulation, packaging

material).

a. Temperature control set too

cold.

a. Adjust door hinges or replace

door gasket.

b. Align fill door hinges.

c. Replace foamed cabinet

assembly (factoryrepair only).

d. Repair light bracket.

Remedy

a. Carefully adjust tubing.

b. Adjust fan mounting or shroud.

c. Remove obstruction.

Remedy

a. Adjust control to warmer setting

(counterclockwise).

Summary of Contents for E24WC48EBS

Page 1: ...1 WINE COOLER SERVICE MANUAL 5995430781 5 2005 ...

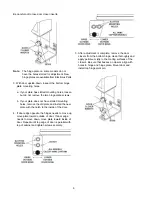

Page 8: ...8 Sample Wiring Diagram Note Always refer to diagram on wine cooler ...

Page 11: ...11 ...

Page 14: ...14 NOTES ...

Page 15: ...15 NOTES ...

Page 16: ...16 ...