7

ENGLISH

Positioning

Install the machine on a flat hard floor.

Make sure that air circulation around the

machine is not impeded by carpets, rugs etc.

Check that the machine does not touch the wall

or other kitchen units.

Carefully level by screwing the adjustable feet in

or out. Never place cardboard, wood or similar

materials under the machine to compensate for

any unevenness in the floor.

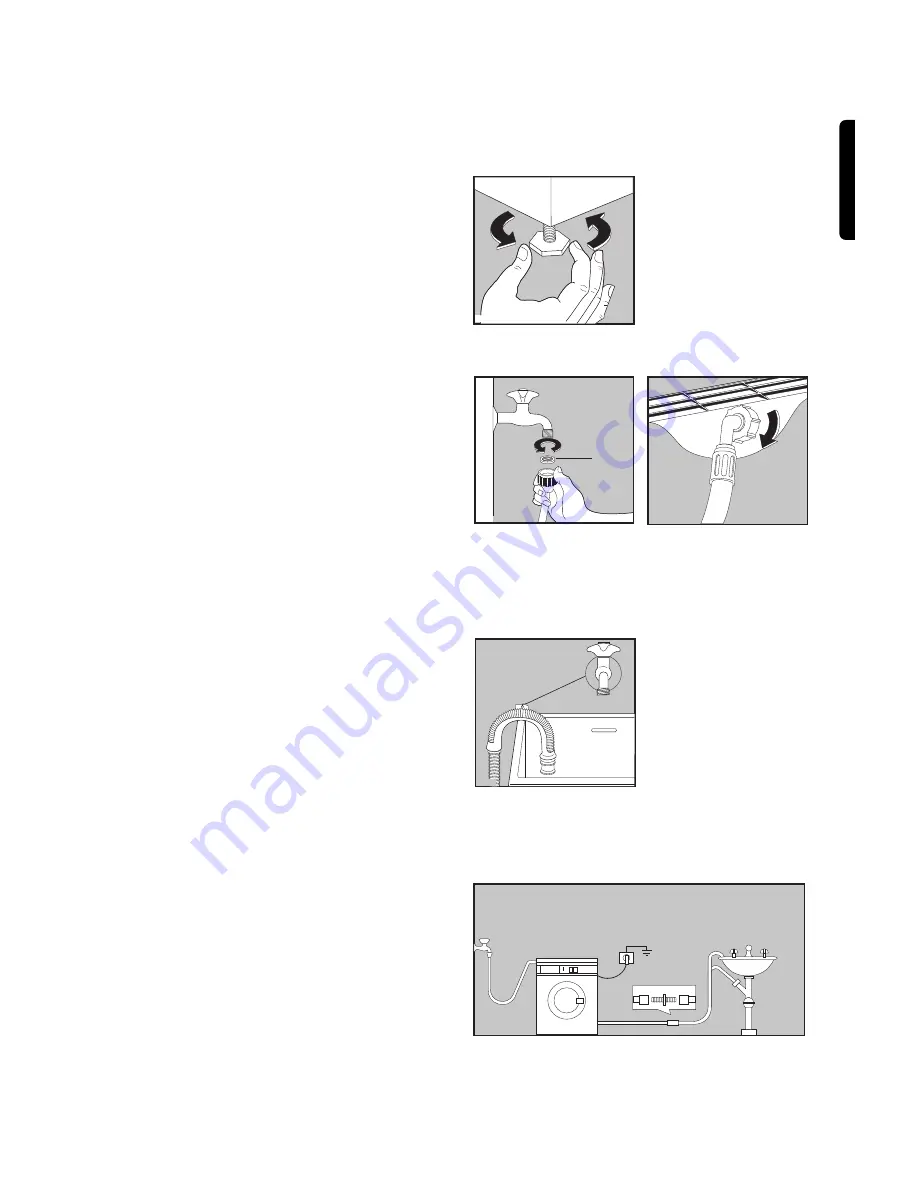

Water inlet

Connect the water inlet hose to a tap with a 3/4"

thread after having inserted the small filter “A”

supplied with the machine.

The other end of the inlet hose which connects

to the machine can be turned in any direction.

Simply loosen the fitting, rotate the hose and

retighten the fitting, making sure there are no

water leaks.

The inlet hose must not be lengthened. If it is

too short and you do not wish to move the tap,

you will have to purchase a new, longer hose

specially designed for this type of use.

Water drainage

The end of the drain hose can be positioned in

three ways:

Hooked over the edge of a sink using the

plastic hose guide supplied with the

machine. In this case, make sure the end

cannot come unhooked when the machine is

emptying.

This could be done by tying it to the tap with a

piece of string or attaching it to the wall.

In a sink drain pipe branch. This branch must

be above the trap so that the bend is at least

60 cm above the ground.

Directly into a drain pipe at a height of not

less than 60 cm and not more than 90 cm.

The end of the drain hose must always be

ventilated, i.e. the inside diameter of the drain

pipe must be larger than the outside diameter of

the drain hose.

The drain hose must not be kinked. Run it along

the floor; only the part near the drainage point

must be raised.

A

P0003

P0022

P0023

P0021

P0850