22

Certain problems are due to lack of simple maintenance or oversights, which can be solved easily

without calling out an engineer. Before contacting your local Service Force Centre, please carry out the

checks listed below.

IMPORTANT: if you call out an engineer to a fault listed below, or to repair a fault caused by incorrect

use or installation, a charge will be made even if the appliance is under guarantee.

During machine operation it is possible that one od the following alarm codes appears on the display and the

End light starts to flash:

-

E10

: problem with the water supply

-

E20

: problem with water draining

-

E40

: door open

Once the problem has been eliminated, press the START/ADD CLOTHES button to restart the programme. If

after all checks, the problem persists, contact your local Service Force Centre.

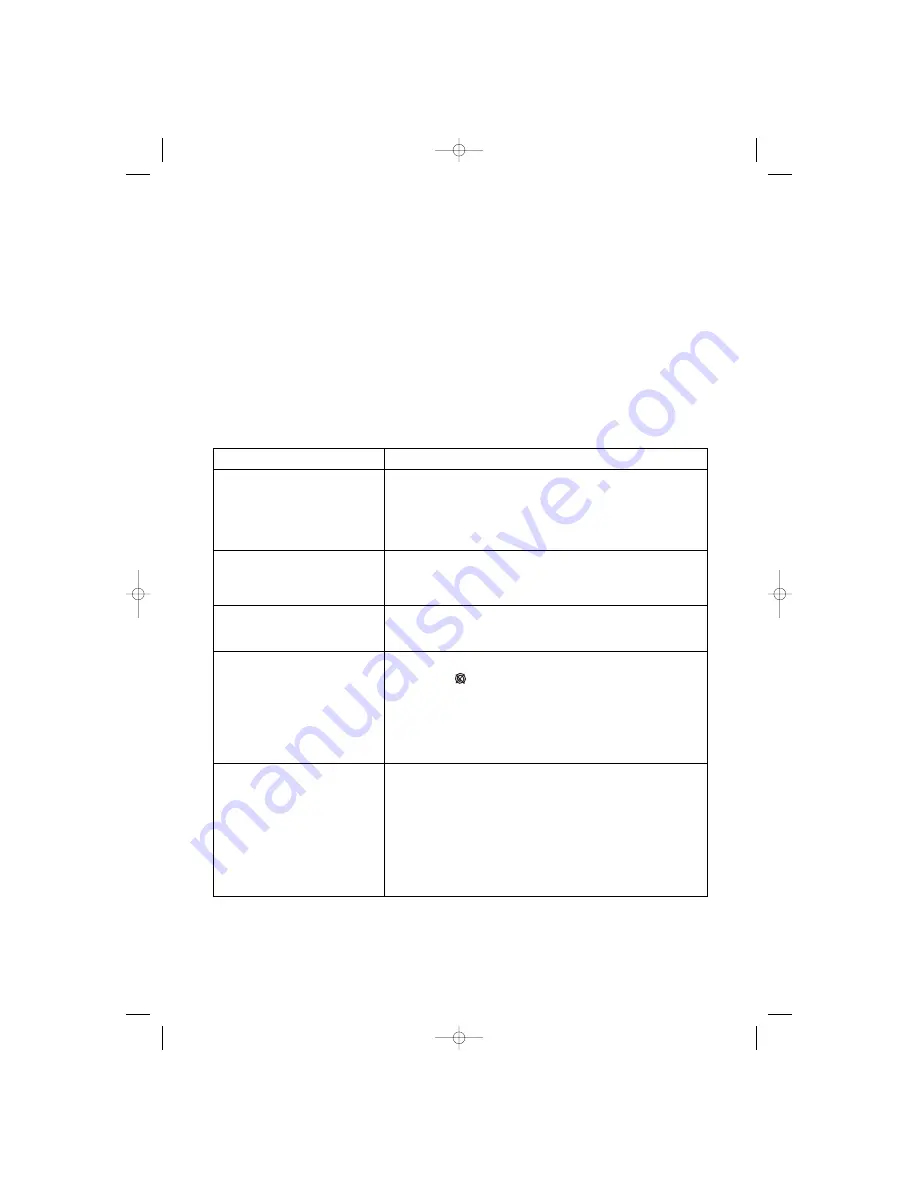

Something not working?

The machine does not

start

The door has not been closed.

(E40)

The plug is not properly inserted in the power socket.

There is no supply at the socket.

The main fuse or the fuse in the plug has blown.

The Start/Add Clothes button has not been pressed.

The DELAY START has been selected.

The machine does not

fill

The water tap is closed.

(E10 )

The filter in the inlet hose is blocked.

(E10 )

The inlet hose may be squashed or kinked.

(E10 )

The door has not been closed.

(E40)

The machine fills then

empties immediately

The end of the drain hose is too low.

The end of the drain hose is submerged in water.

There is no vent in the end of th

A

drain hose.

The machine does not

empty and/or does not

spin

The drain hose may be squashed or kinked.

(E20)

The option

has been selected.

The drain pump may be blocked.

(E20)

The drain hose extension, if fitted, is not correct. Follow the

instructions for connecting to the waste.

The drainage system pipes are blocked.

The wash load is unbalanced: redistribute the clothes inside the

drum to allow the machine to spin.

There is water

on the floor

Too much detergent or unsuitable detergent has been used

(creates too much foam).

Check whether there are any leaks from the inlet hose fittings.

It is not always easy to see this as the water runs down the hose;

check to see if it is damp.

The drain hose may be damaged or not securely positioned.

The detergent dispenser drawer or recess is clogged.

The drainage system pipes are blocked.

The cap on the emergency emptying hose has not been

replaced after cleaning the pump.

Possible causes

Problem

im_ewf1090_uk.qxd 07/09/2005 12:22 Pagina 22