SOI/DT 2002-07 eb

28

599 35 36-69

6.2 Door interlock

There are two types of door interlock:

•

voltmetric with PTC: it is always necessary to wait from 1 to 2 minutes from the end of the cycle before

opening the door.

•

instantaneous: the door can be opened as soon as the cycle ends.

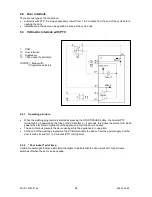

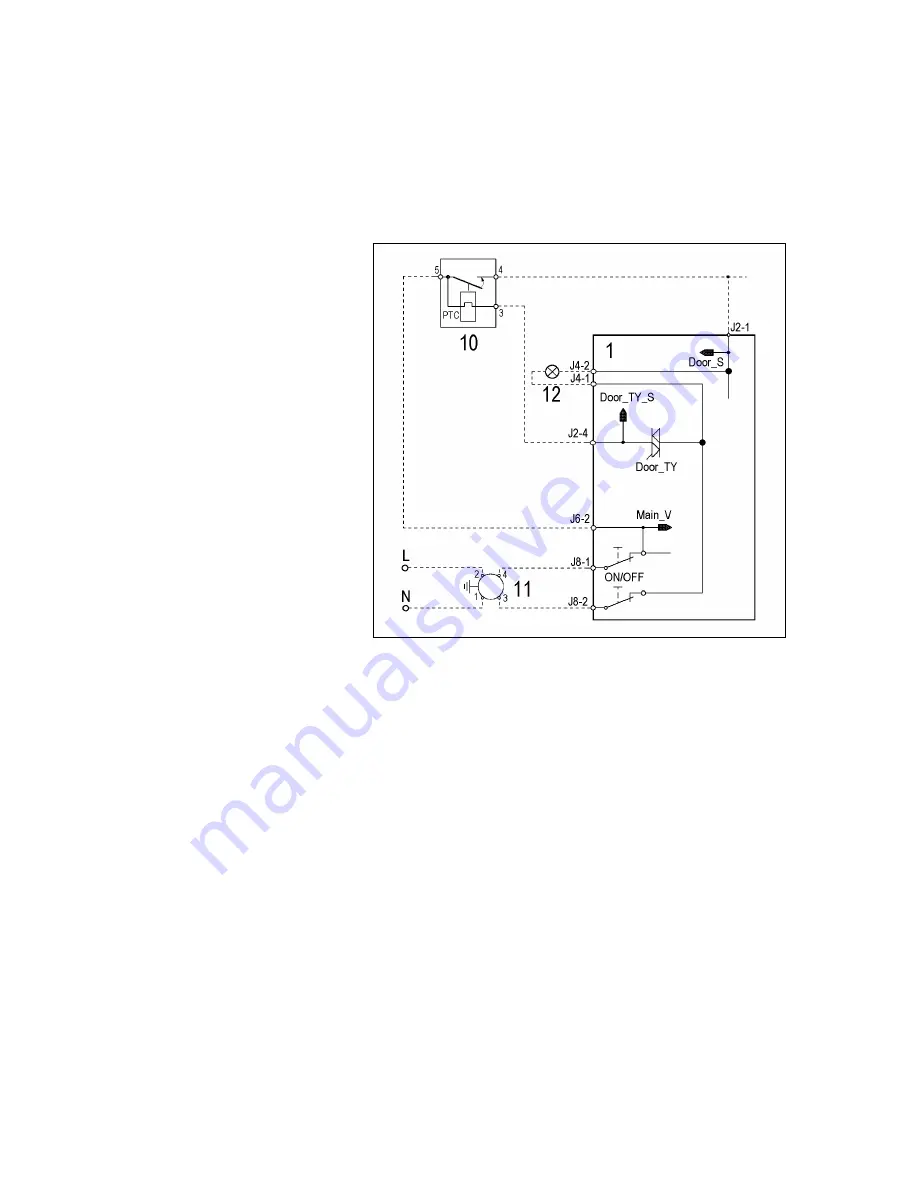

6.3 Voltmetric interlock with PTC

1 PCB

10 Door interlock

11 Suppressor

12 (“Door locked” pilot lamp)

ON/OFF = Main switch

(Programme selector)

6.3.1 Operating principle

•

When the washing programme is started by pressing the START/PAUSE button, the bimetal PTC

(contacts 3-5) is powered by the triac on the PCB: after 2 – 4 seconds, this closes the switch (5-4) which

powers the electrical components of the appliance (only if the door is closed).

•

The door interlock prevents the door opening while the appliance is in operation.

•

At the end of the washing programme, the PCB disconnects the device from the power supply, but the

door remains locked for 1 to 2 minutes (PTC cooling time).

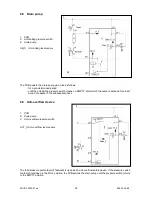

6.3.2 “Door locked” pilot lamp

Certain models might feature a pilot lamp that lights to indicate that the door is locked. This pilot lamp

switches off when the door can be opened.