Summary of Contents for EWM1000

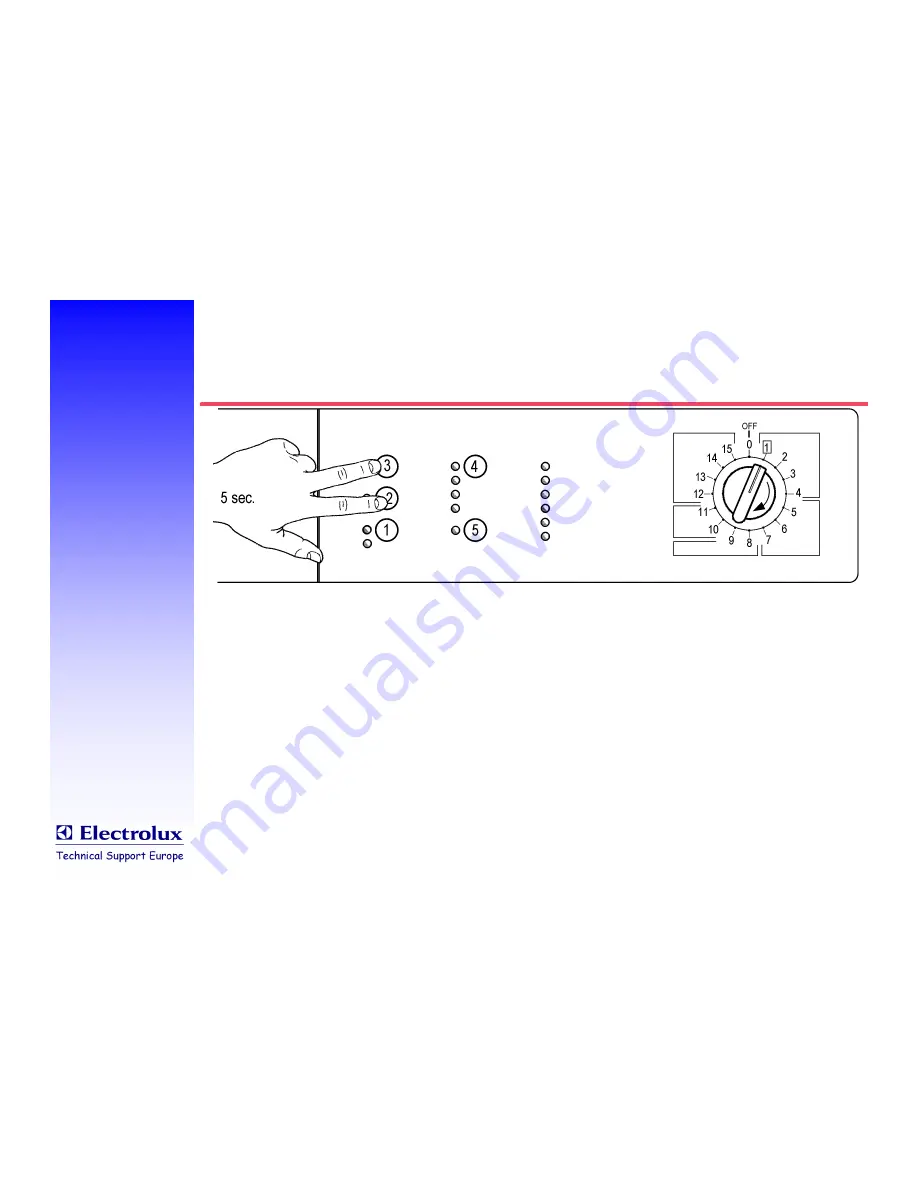

Page 1: ...1 TSE N A S February 2002 EWM 1000 DIAGNOSTICS FAULTFINDING ...

Page 33: ...33 TSE N A S February 2002 Component Diagnostic Connector Identification ...

Page 37: ...37 TSE N A S February 2002 Motors ...

Page 50: ...50 TSE N A S February 2002 NTC Characteristic ...