Guide to diagnostics of electronic controls EWM10931

2011 SOE/DT-mdm FCPD-dp Quality-tb

61/75

599 73 77-37

Checks to perform:

E91: Communication error between the display board

and the main circuit board

E91

Inconsistency between configuration values on starting the appliance

E91

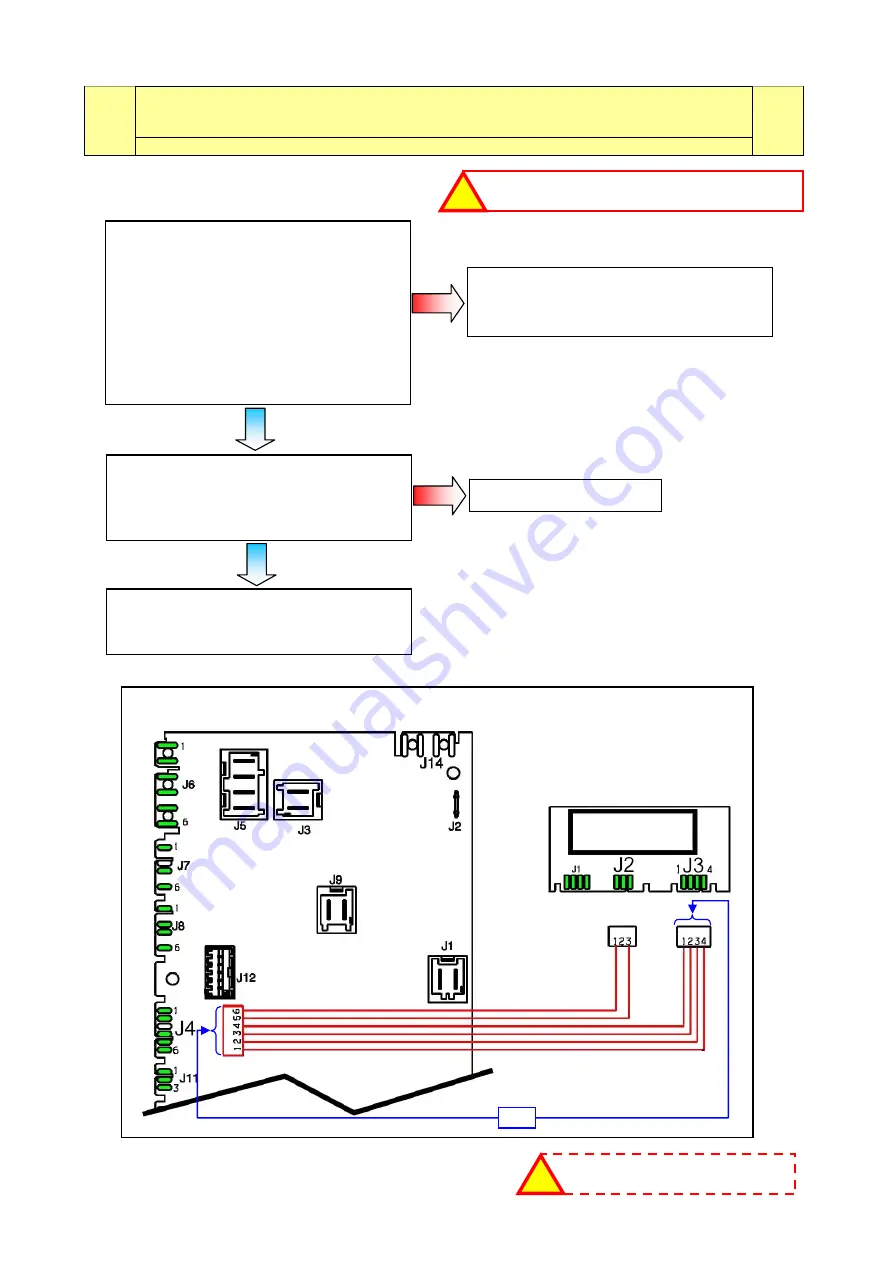

Check the wiring between the main circuit

board and the display board:

►

Detach and reconnect the connectors

on both boards several times.

►

Measure the continuity between

connector J4 (main circuit board)

and J3 (display board).

Is the wiring ok?

Replace the main circuit board and repeat

the diagnostic cycle to check for any

further alarms.

Is the appliance still displaying E91?

Replace / repair the wiring and repeat

the diagnostic cycle to check for any

further alarms.

NO

Y

E

S

Appliance ok.

NO

Replace the display board and repeat

the diagnostic cycle to check for any

further alarms.

Y

E

S

If there are burns on the circuit

board, see page 73

!

Check that all the connectors are correctly inserted

!

MAIN CIRCUIT

BOARD

DISPLAY

CIRCUIT BOARD

0

Ω