2-15

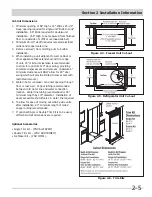

Door Handle Mounting Instructions

For some installations the door handle may need to be

removed. (See Figure 2-30)

To remove the door handle:

1. Remove screw cover plates by pushing in and

sliding the screw cover plate off of the door handle.

2. Using a phillips head screwdriver, extract the screws

securing the door handle to the door assembly.

3. Push upwards until the screw button assembly is free

of the dovetail inside the handle assembly.

Care & Cleaning Of Your Trim Kit

The trim and grill kit surfaces are best cleaned with a

cotton cloth dampened with a mixture of water and mild

detergent. Avoid using abrasive cleaners as they will

mar the surface of the metal components.

Door Removal

For some installations it may be necessary to remove the

door to fit through the entrance of the installation site.

To remove the door, follow the steps below.

1. Make sure electrical plug is disconnected from the

wall outlet.

2. Gently lay freezer on its back on a soft clean

surface.

3. Lift plastic cover off upper hinge assembly.

(See Figure 2-28)

3. Using a 3/8” socket or wrench, extract the two bolts

securing the upper hinge to the unit frame.

4. Remove kickplate.

5. Using a 3/8” socket or wrench, extract the two bolts

securing the lower hinge to the unit frame. Use a

phillips head screwdriver to extract the remaining

screw from the lower hinge assembly.

(See Figure 2-29).

7. Lift the door assembly off of the unit frame.

Figure 2-28. Top Hinge Removal

Figure 2-29. Bottom Hinge Removal

Hinge Cover

3/8” Bolts

Hinge Plate

Section 2 Installation Information

Figure 2-30. Handle Removal

Set Screws

Summary of Contents for FPUH17D7KF All Freezer Professional Series

Page 2: ......

Page 20: ...Section 2 Installation Information 2 12 Figure 2 20 Figure 2 21 ...

Page 21: ...Section 2 Installation Information 2 13 Figure 2 22 Figure 2 23 ...

Page 24: ...Section 2 Installation Information 2 16 Notes ...

Page 26: ...Section 3 Electronic Control 3 2 Notes ...

Page 41: ...Section 4 Refrigeration 4 15 HFC 134a CFC 12 Pressure Temperature Chart ...

Page 44: ...Section 4 Refrigeration 4 18 Notes ...

Page 68: ...Section 6 Parts List 6 2 All Refrigerator Cabinet Exploded View And Parts List ...

Page 70: ...Section 6 Parts List 6 4 All Refrigerator Sealed System Exploded View And Parts List ...

Page 72: ...Section 6 Parts List 6 6 All Freezer Door Exploded View And Parts List ...

Page 74: ...Section 6 Parts List 6 8 All Freezer Cabinet Exploded View And Parts List ...

Page 76: ...Section 6 Parts List 6 10 All Freezer Sealed System Exploded View And Parts List ...

Page 78: ...Section 6 Parts List 6 12 Notes ...

Page 82: ...Section 7 Troubleshooting 7 4 Notes ...

Page 83: ...Section 8 Wiring Diagram 8 1 All Refrigerator Wiring Diagram ...

Page 84: ...8 2 Section 8 Wiring Diagram All Freezer Wiring Diagram ...