Section 4 Refrigeration

4-13

Vacuum Pump Maintenance

It is absolutely essential to maintain your vacuum pump

according to the manufacturer’s instructions including

required oil changes at the recommended intervals.

Vacuum pump oil should always be changed after

evacuating a contaminated system. Vacuum pump

performance should be checked periodically with a

micron gauge.

Vacuum pump suppliers may or may not recommend

changing the vacuum pump oil to the same type that’s in

the system being evacuated. Some manufacturers may

recommend a vacuum pump that’s dedicated to R-134a

systems.

Robinair has stated that their current and discontinued

vacuum pump models, using mineral oil currently

specified for use in their vacuum pumps, can be used to

evacuate R-134a/Ester oil systems. Robinair also states

that it is acceptable to alternate between evacuating

R-12/mineral oil and R-134a/Ester oil systems without

adversely effecting the vacuum pump’s performance.

For other brands of vacuum pumps, check with the

manufacturer for restrictions and guidelines when using

with R-134a.

Refrigerant Leaks

A system with R-134a and Ester oil will become

saturated with moisture much faster than a system with

R-12 and mineral oil. If your leak was in the low side of

the refrigeration system when the compressor is

running the pressure in the low side will go into a

vacuum. As additional refrigerant leaks out the system

will go deeper into a vacuum. The system running in

this vacuum will allow air and moisture to be pulled into

the sealed system. The moisture pulled in can then be

mixed in to the Ester oil in the compressor.

If the product has had a low side leak you will need to

install the two stage service dryer filter part number

5303918288. You must heat the crankcase area of the

compressor using a heat gun on the high heat setting

throughout the 30 minutes you are running your

vacuum pump to pull a vacuum on the system. Every 4

to 5 minutes while you are running your vacuum pump

and heating the crankcase area, shake the compressor.

By heating the crankcase you are heating the oil in the

compressor. This will drive the moisture out of the oil.

By shaking the compressor this will allow the moisture

to come to the top of the oil faster so the vacuum pump

can remove the moisture from the system.

Electrolux Home Products does not approve the use of

the Sweep Charge for sealed system repair. This method

of servicing sealed systems is often used to repair

products in the field. The Sweep Charge does not

adequately remove moisture from the oil in the

compressor. In a R-134a system you will need to replace

the compressor if the product has had a low side leak

and you are servicing with the Sweep Charge

procedure.

R-134a refrigerant molecules are smaller than R-12

molecules. This means that R-134a will pass more minor

leaks and the rate of flow will be greater than for R-12.

Therefore, it is now more important than ever to follow

good brazing practices. Use a good grade of silver

solder. A 45% silver solder is recommended.

If you use a vacuum pump with mineral oil to

evacuate an R-134a system, it is ABSOLUTELY

ESSENTIAL to have a shut-off valve between

pump and your manifold gauge set as shown

on page 4-10. The hand valve must be closed

during all times when vacuum pump is not

operating. This will prevent migration of

mineral oil vapor into R134a/Ester oil system.

If vacuum pump should stop during evacuation

for any reason, the hand pump shut-off valve

must be closed immediately.

CAUTION

Summary of Contents for FPUH17D7KF All Freezer Professional Series

Page 2: ......

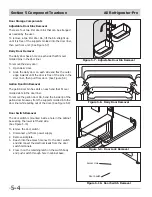

Page 20: ...Section 2 Installation Information 2 12 Figure 2 20 Figure 2 21 ...

Page 21: ...Section 2 Installation Information 2 13 Figure 2 22 Figure 2 23 ...

Page 24: ...Section 2 Installation Information 2 16 Notes ...

Page 26: ...Section 3 Electronic Control 3 2 Notes ...

Page 41: ...Section 4 Refrigeration 4 15 HFC 134a CFC 12 Pressure Temperature Chart ...

Page 44: ...Section 4 Refrigeration 4 18 Notes ...

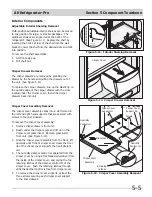

Page 68: ...Section 6 Parts List 6 2 All Refrigerator Cabinet Exploded View And Parts List ...

Page 70: ...Section 6 Parts List 6 4 All Refrigerator Sealed System Exploded View And Parts List ...

Page 72: ...Section 6 Parts List 6 6 All Freezer Door Exploded View And Parts List ...

Page 74: ...Section 6 Parts List 6 8 All Freezer Cabinet Exploded View And Parts List ...

Page 76: ...Section 6 Parts List 6 10 All Freezer Sealed System Exploded View And Parts List ...

Page 78: ...Section 6 Parts List 6 12 Notes ...

Page 82: ...Section 7 Troubleshooting 7 4 Notes ...

Page 83: ...Section 8 Wiring Diagram 8 1 All Refrigerator Wiring Diagram ...

Page 84: ...8 2 Section 8 Wiring Diagram All Freezer Wiring Diagram ...