SOI/DT 2006-01 dmm

39/71

599 37 47-13

5.6 Pressure

switch

5.6.1 General

characteristics

The function of the pressure switch is to determine the quantity of water to

be introduced into the tub. In other words:

Ö

It controls the water fill levels during the washing phases.

Ö

It acts as an anti-boiling safety device when connected in series to the

heating element.

Ö

It can also act as an anti-overflow safety device if connected in series to

the drain pump.

Ö

It can act as an anti-foam device during the spin phases.

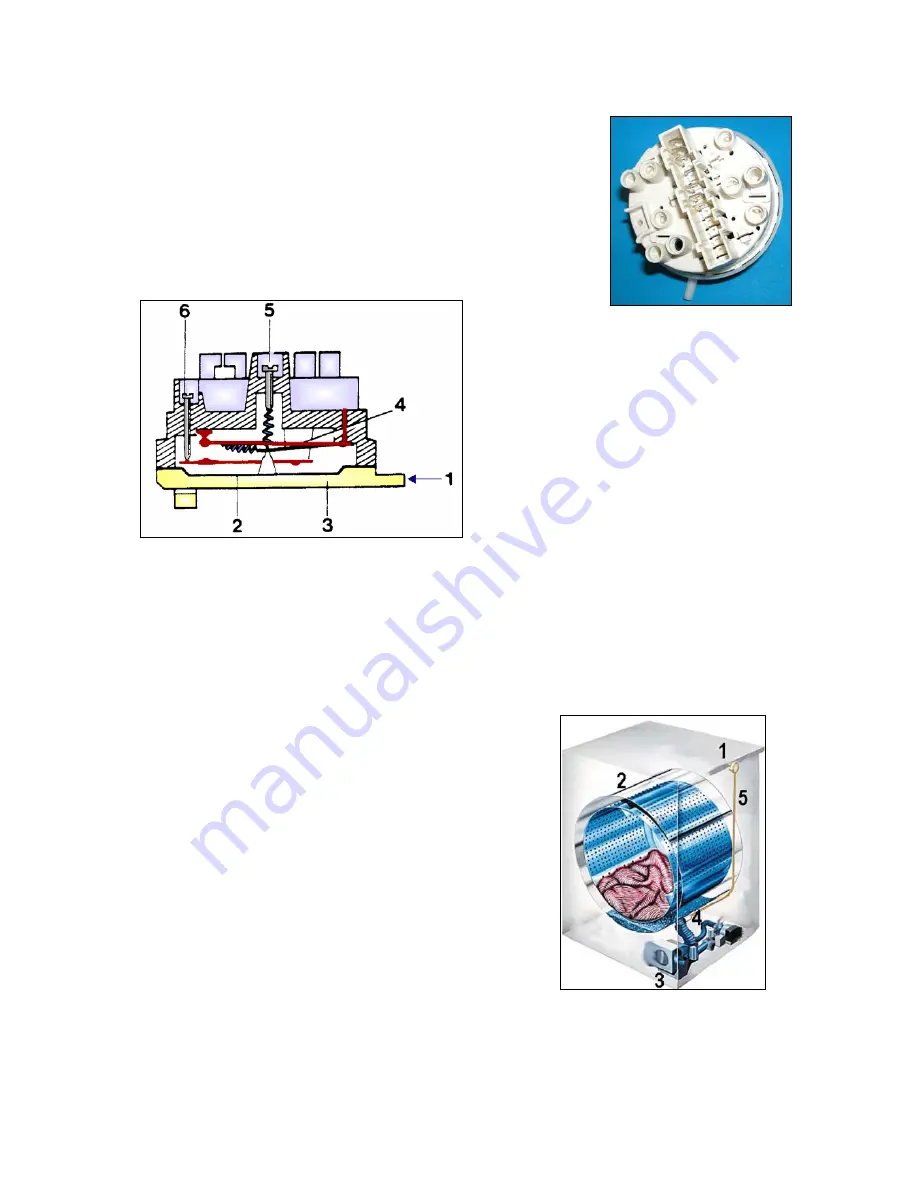

1. Air inlet aperture

2. Diaphragm

3. Internal

chamber

4. Contact strip (rapid cut-in)

5. Level regulation screw

6. Differential regulation screw

The internal chamber is connected via a small tube to the pressure chamber. When water is introduced into

the tub, the pressure in this chamber increases. When the pressure reaches a pre-determined level, the

membrane causes the contact strip to trip (rapid-action), which switches the contact from "empty" to "full".

Two regulation screws are fitted to the cover, one for the level, the other for the differential, i.e. the point at

which the strip returns to the "empty" position when the level of water in the tub decreases.

5.6.2 Pressure switch hydraulic circuit

1. Pressure

switches

2. Tub

3. Filter

body

4. Pressure chamber on the tube between the tub

and the filter body

5. Pressure switch tubes

Normally, all appliances are fitted with one or two

pressure switches (in rare cases, an appliance may

feature three pressure switches). Each pressure

switch controls from one to three levels of water in

the tub.

The small tube from the pressure switches may be

connected to the pressure chamber, which is located

beneath the tub.

One or two pressure switches may be connected to

the pressure chamber, depending on the model.