24

J6

Operation

The filling and heating phase stops when the display

shows the tank temperature:

The equipment is then ready for use:

•

Open the door.

•

Insert the rack with the dirty dishes.

•

Close the door and select the required wash cycle;

the relevant indicator lights up and the wash cycle

starts.

•

If the dishwasher is equipped with detergent and

rinse aid level sensors the message

may

appear on the display. This indicates no detergent

in the external tank.

After 5 cycles performed with a lack of detergent,

the dishwasher inhibits the start of other wash

cycles. Therefore the detergent level in the tank

must be restored (see par. “Manual activation”).

•

The lack of rinse aid is signaled by the message

; this message is a warning that does not

stop execution of the wash cycles.

Wash cycle selection:

- Cycle I

For not very dirty dishes or glasses: press the button

“J” (Table 2), (see times table).

- Cycle II (advisable)

For normally dirty dishes: press the button “H”

(Table 2), (see times table).

•

To stop the wash cycle, just press the button of the

selected cycle, or open the door.

•

To continue the wash, press the selected cycle button

again, or close the door. The cycle will resume from

where it was stopped.

•

At the end of the wash, a series of beeps will sound

and “END” will flash on the display.

Open the door and remove the rack with the clean

dishes.

WARNING

-

Our equipment cannot remove burnt grime

deposited on the dishes. Do a mechanical/

chemical pretreatment (e.g. prewash under

running water) before putting dishes with this

type of grime in the machine.

-

The use of “foaming”/non-specific deter-

gents or in any case detergents used in differ-

ent ways from that prescribed by the

producer, can cause damage to the dish-

washer and compromise washing results.

-

Failure to remove the detergent residues, pos-

sibly used for manual prewash, can cause

dishwasher malfunction and compromise

washing results.

ATTENTION

Change the tank water at least twice a day.

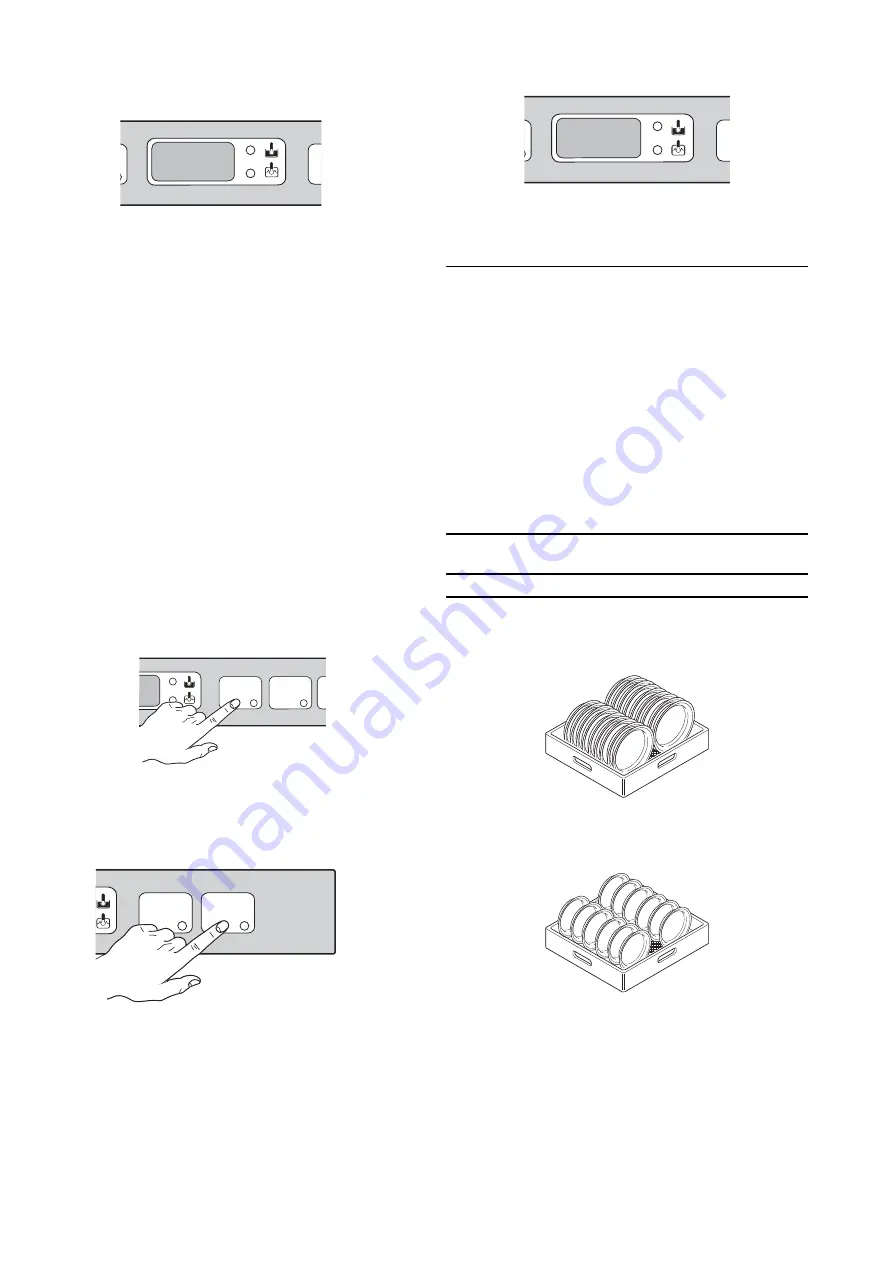

Rack loading type

•

YELLOW rack: 18 flat plates of max width 240 mm.

Figure 20

YELLOW rack

•

GREEN rack (optional): 12 soup plates of max

width 240 mm.

Figure 21

GREEN rack

55°C

55°C

1

2

1

2

END