6

electrolux

installation manual

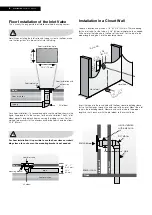

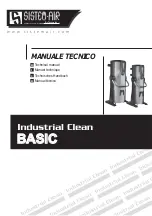

Floor Installation of the Inlet Valve

This is usually the only possible installation method in existing houses.

Note! When installing the inlet valve and tubing system in the floor, make

sure that long sticks etc. do not to fall into the tubing.

For floor installation, it is possible to use the floor sleeve or rebuil-

ding sleeve. In such cases, the mounting bracket is not needed.

2 1/4” (55 mm)

tubing

floor installation hole

2 3/4” (70 mm)

floor inlet valve

floor installation with

extension

90° elbow

tubing

floor insulation

floor

90° elbow

mounting bracket

floor inlet valve

pipe

2 3/4”

(65 mm)

1/4” - 1”

(5–25 mm)

floor insulation

floor

Choose a location and make a 2 1/8” x 2 3/4” (55mm x 70mm) opening

for the inlet valve. For the tube, a 2 3/8” (60mm) diameter hole is needed.

Drill a hole for the tube also in the floor of the closet. Cut the tube to the

proper length and glue it into the rebuilding sleeve.

Insert the tube into the round hole with the floor sleeve/rebuilding sleeve

first so that it extends through the outer wall of the closet. Mount the inlet

valve in the rebuilding sleeve. Measure and cut the tube to the proper

length so that it reaches with the inlet elbow to the vertical tube.

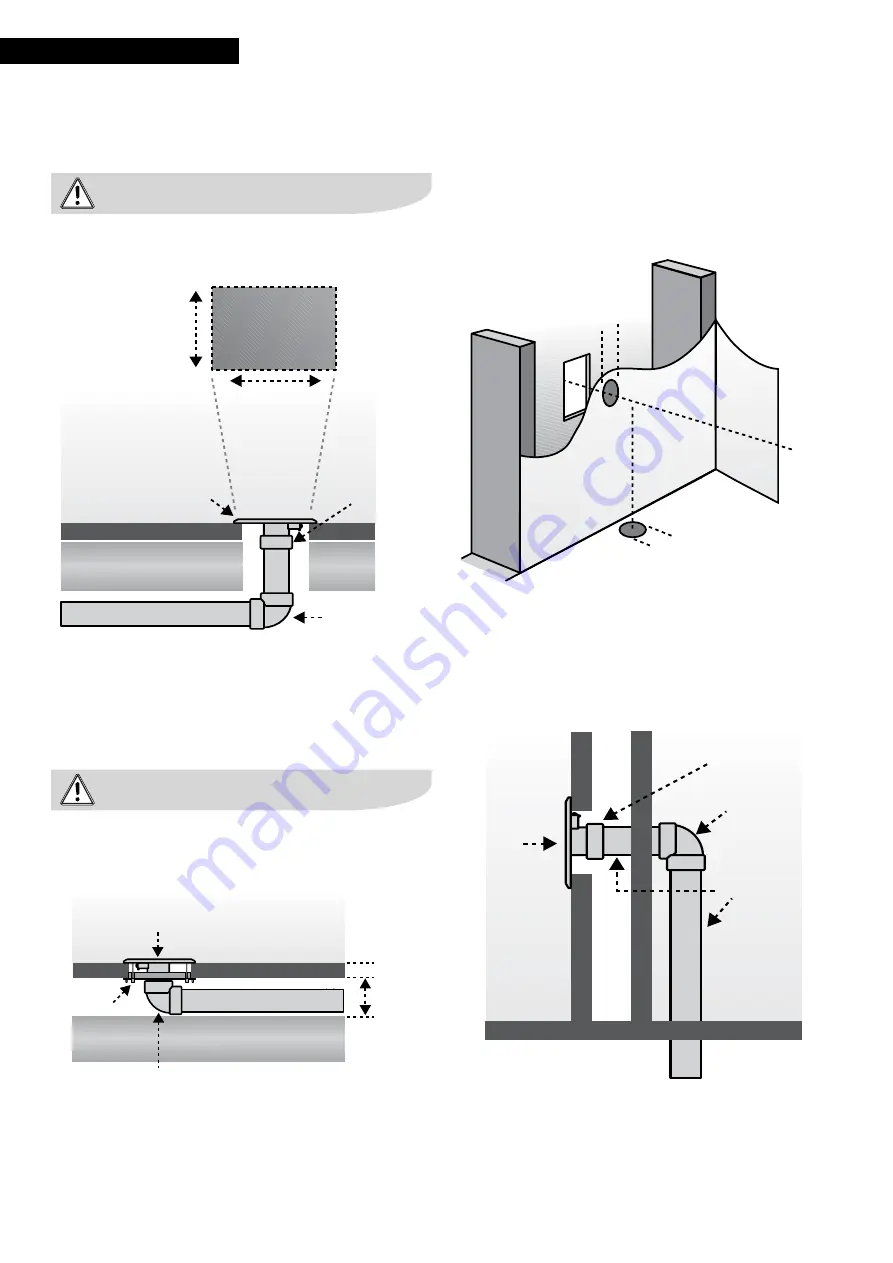

Installation in a Closet Wall

2 3/8”

(60 mm)

2 1/4”

(55 mm)

2 1/4” - 2 1/2”

(57–62 mm)

interior wall

closet floor

closet wall

2 3/4” (70 mm)

interior room

inlet valve

wall installation

with extension

90° elbow

pipe

floor

interior wall

closet wall

For a floor installation, it is recommended to use the method shown in the

figure, if applicable. It is the same as for the wall installation. The 90° inlet

elbow prevents long objects from accessing the tubing system. For this

method to be successful, the allowance under the floor should be at least

2 2/3” (65mm).