electrolux

installation manual

7

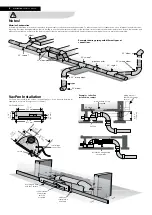

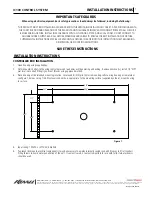

1) The 90° inlet elbow may be installed only together with the mounting

bracket and the inlet valve. Anywhere else in the tubing system, 90°

sweep elbows and 45° elbows should be used. (Fig. A and B)

2) Tubes are cut straight so that the cutting line is not slanted. Use a miter

saw if possible. Cut edges can be finished with a knife (to remove burrs).

3) For tubing joints, use suitable PVC glue to make the fittings secure and

tight. Apply a thin and even layer of glue only to the end of the tube – not

to the sleeve. This will prevent the glue from overflowing to the end face

of the tubing. Close the glue can carefully immediately after use and make

sure to have adequate ventilation during installation. Avoid inhaling glue

vapors. Insert the tube all the way into the sleeve while turning it at the

same time (Fig. C).

4) The inlet is made through the fire wall according to Fig.figure E or by

using a 2” (50mm) diameter fire cuff (Fig. D). Check the inlet with a fire

authority.

mounting bracket

90° elbow

90°

sweep

elbow

A

B

Tubing System Installation

Important notes for installation!

correct

incorrect

incorrect

pipe collars are attached

to the wall

wire mesh

concrete

sand

vacuum pipe electrical tube

2” (51 mm)

fire stopping pipe

collars

E

F

correct

correct

incorrect

D

min. 3/4” (18 mm)

push the pipe completely into the fitting

C

Begin the main tube installation with the farthest inlet valve and place the

tubes temporarily at first. Do not glue the joints yet until you have made

sure that the tubing routing is correct. The glue will dry quickly; therefore,

the joints have to be fitted right after applying the glue.

When measuring the tubes, take into account that the tube goes appro-

ximately 2/3” (18mm) into the sleeve and approximately 7/8” (20mm) into

the extension tube.

The tubing system can also be installed in a floor that will be concrete

casted later on (Fig. F). In such cases, the low-voltage cable must be

protected by a conduit pipe. The conduit pipe should be attached to the

vacuum tube or the casting net. For the vacuum tube, the routing channel

has to be 2” wide (51mm). The ends of the vacuum tubes and the con-

duit pipes should be plugged before concrete casting.

vacuum pipe

wall

vacuum pipe

min. 7 7/8”

(200 mm)

protects the combustible

building material

steel protective sleeve

min. 1/ 16” (2 mm)

wall

Installation Examples