Doc. No.:

560001 EG

Page:19

Ed.1" 08-2014

From ser. no.:

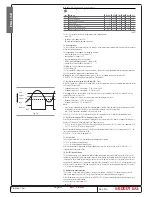

accensione strumento

power ON

ON

ON

OFF

ON

OFF

OFF

C0

richiesta di intervento

insertion request

compressore

compressors

ON

ON

OFF

OFF

C1

richiesta inserimento

insertion request

compressore

compressors

ON

ON

OFF

OFF

C2

richiesta inserimento

insertion request

compressore

compressors

ON

ON

OFF

OFF

C3

richiesta inserimento

insertion request

compressore

compressors

ON

OFF

C4

compressore

compressors

OFF = 15 min.

Fig. 7.d

Fig. 7.e

Fig. 7.f

Fig. 7.g

Fig. 7.h

ENGLISH

7.3 Compressor management parameters

Code

Parametro

Models

U.M.

Type Min

Max

Def.

c0

Compressor, fan and AUX start delay on power up in dead zone

-SYF

min

C

0

15

0

c1

Minimum time between successive starts

-SYF

min

C

0

15

0

c2

Minimum compressor OFF time

-SYF

min

C

0

15

0

c3

Minimum compressor ON time

-SYF

min

C

0

15

0

c4

Duty setting

-SYF

min

C

0

100

0

cc

Continuous cycle duration

-SYF

hours

C

0

15

0

c6

Alarm bypass after continuous cycle

-SYF

h/min

C

0

250

2

c7

Maximum pump down time

-SYF

s

C

0

900

0

c8

Comp. start delay after open PD valve

-SYF

s

C

0

60

5

c9

Enable autostart function in PD

-SYF

fl ag

C

0

1

0

c10

Select pump down by time or pressure

-SYF

fl ag

C

0

1

0

c11

Second compressor delay

-SYF

s

C

0

250

4

Tab. 7.d

c0: Compressor and fan start delay (if ‘FAN’ relay present) on start-up

When the controller is switched on, the compressor and the evaporator fans and the auxiliary relay in control with dead band (H1 or

H5=11) start after a delay (in minutes) equal to the value set for this parameter, in order to protect the compressor against repeated

power-ups in the event of frequent power drops. Default: c0=0 => no minimum delay is set.

Example:

setting c0=6 forces the compressor to wait 6 minutes before starting from when power returns. In the event of systems

with more than one compressor, the parameter c0 can also be used to avoid simultaneous starts of a series of units. Simply set

a diff erent value of c0 for each compressor.

Note:

the second compressor step, for the aux 1 or 2 output (‘H1 or H5’=12, 13), is

associated with the timers ‘c0’, ‘c1’, ‘c2’, ‘c3’.

c1: Minimum time between two successive starts of the compressor

Sets the minimum time (in minutes) that must elapse between two starts of the compressor, irrespective of the temperature and the

set point. Setting this parameter limits the number of starts per hour.

Default: c’=0 => no minimum time is set between two starts.

Example:

if the maximum number of activations/hour allowed is 10, simply set c1=6 to ensure that this limit is respected. Note:

the second compressor step, for the aux 1 or 2 output (‘H1 or H5’=12, 13), is associated with the timers ‘c0’, ‘c1’, ‘c2’, ‘c3’.

c2: Minimum compressor OFF time

SSets the minimum time (in minutes) for the compressor to remain OFF. The compressor is not started again until the minimum

time selected (c2) has elapsed from when it last stopped.

Note:

this parameter is useful to ensure the balancing of the pressure after the compressor stops for systems with hermetic and

capillary compressors. The second compressor step, for the aux 1 or 2 output (‘H1 or H5’=12, 13), is associated with the timers

‘c0’,‘c1’,‘c2’,‘c3’.

c3: Minimum compressor ON time

Sets the minimum running time for the compressor. The compressor is not stopped until it has been ON for at least the minimum

time selected (c3).

Note:

the second compressor step, for the aux 1 or 2 output (‘H1 or H5’=12, 13), is associated with the timers

‘c0’,‘c1’,‘c2’,‘c3’.

Default: c3=0 => no minimum running time is set.

c4: Duty setting

If the virtual control probe fault alarm occurs (see parameter ‘/4’), this parameter is used to ensure the operation of the compres-

sor until the fault is resolved.

Default: c4=0 => compressor always Off in the event of a virtual control probe error.

Important:

In the event of errors on probe 2, the virtual probe corresponds to the room probe (probe 1) and consequently the

Duty Setting is not activated.

In practice, as the compressor is no longer able to operate based according to the temperature (due to the probe fault), it is made

to run cyclically with an operating time (ON time) equal to the value assigned to parameter c4 (in minutes) and a fi xed OFF time

of 15 minutes.

There are two values of c4 that cause special behaviour:

c4=0, in the event of faults involving the virtual control probe, the compressor is always OFF;

c4=100, the compressor is always ON, that is, the 15 minute OFF time is always ignored.

Special situations:

• if the virtual control probe error occurs while the compressor is OFF, it remains OFF for 15 minutes, and is then started

(respecting the times set for parameters c1 and c2) and remains ON for a time equal to c4, Duty Setting. This special operation is

signalled by the LED that fl ashes during the compressor OFF period, and remains on steady when the compressor is operating.

The fans continue to operate according the set parameters (see F parameters). If the duty setting requires the immediate shut-

down of the compressor for a non-specifi ed time (c4= 0), this is done without observing the compressor protection times.

• if the virtual control probe error occurs while the compressor is ON, it remains ON for the time c4, and then is stopped (without

observing the minimum ON time, if set for parameter c3) and remains OFF for 15 minutes (the LED fl ashes in this phase).

After this, cyclical operation starts, with an operating time equal to the value of c4.

Warning:

If the virtual probe error disappears, the unit returns to normal operation.

Note:

if control with two compressor steps is selected (with or without rotation, ‘H1 or H5’= 12 or 13), the duty setting acts on

both steps.