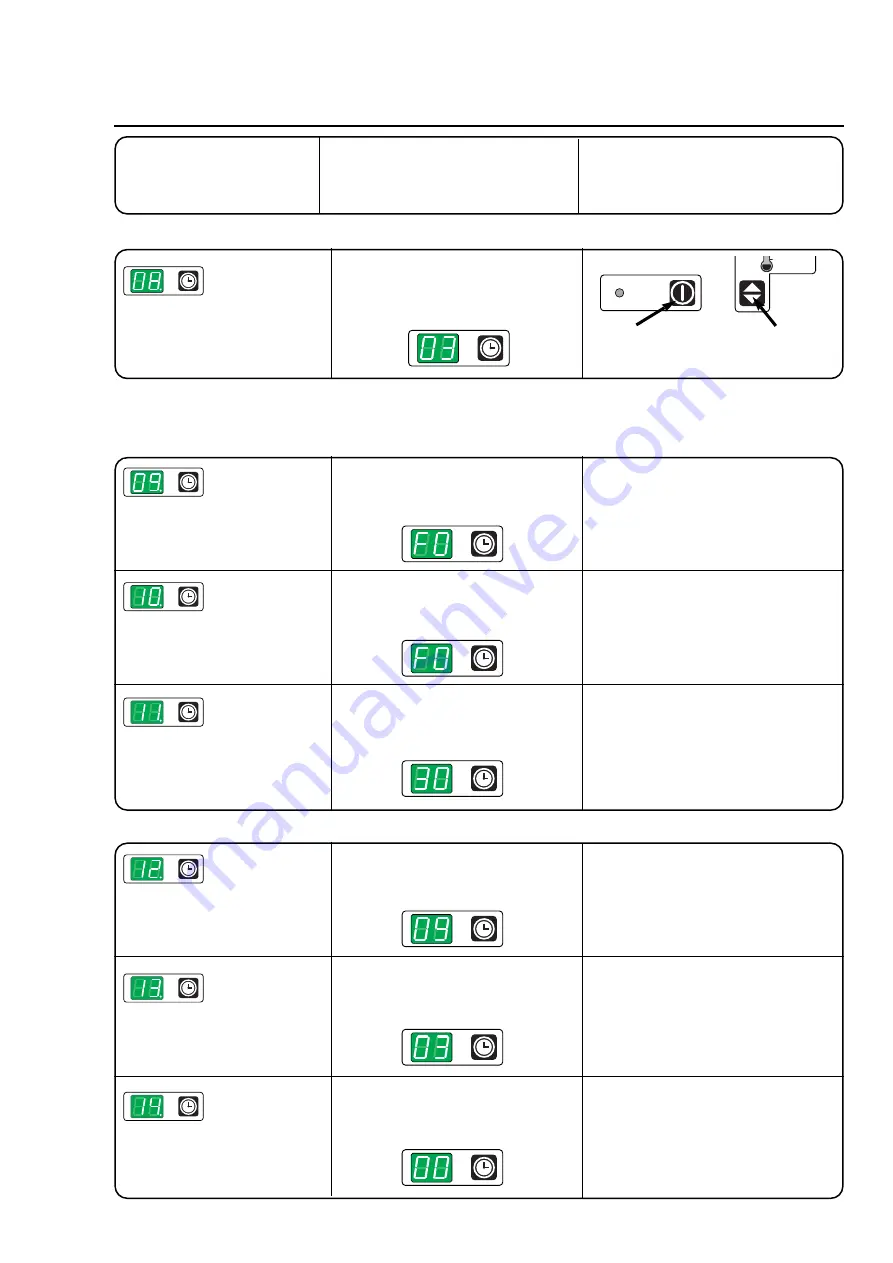

Parameter programming

49

487 18 39 01 - 300/500/750 - GB

Program

P1 =

extra dry

Program

P2 =

ready to put away

Program

P1 =

extra dry

Extra drying

time

in minutes

Extra drying

time

in minutes

Program

P3 =

ironing dry

Extra drying

time

in minutes

Residual

moisture level,

F0 = ready

to put away

Program

P3 =

ironing dry

Residual

moisture level,

F0 = ready

to put away

Residual

moisture level,

e.g. 30 =

iron dry

Cooling time

Residual moisture level

The measurement of residual moisture level consists of a combined parameter set for residual

mo a parameter for extra drying time.

Extra drying time

Cooling time

Running time

without

heat at end of

cycle

Count down

Count up

-- --

Can be set to a value

between 00 and 10 minutes.

Factory setting = 03

Can be set to a value

between 05 and F0.

Factory setting F0

Can be set to a value

between 05 and F0.

Factory setting F0

Can be set to a value

between 05 and F0.

Factory setting 30

Can be set to a value

between 00 and 20 minutes.

Factory setting 09

Can be set to a value

between 00 and 20 minutes.

Factory setting 03

Can be set to a value

between 00 and 20 minutes.

Factory setting 00

Extra drying time when the value set

in parameter 09 has been reached.

The values for residual moisture are

given in hexadecimals (05-F0). See

explanation on following page.

Extra drying time when the value set

in parameter 10 has been reached.

Extra drying time when the value set

in parameter 11 has been reached.

Parameter no.

check by pressing

the clock button

Value

can be set after two seconds

Required change:

Press the “count up/down” buttons.

Program

P2 =

ready to put away

Summary of Contents for TT300

Page 1: ...Operating and installation manual TT300 TT500 TT750 487 1839 51 01 99 31 ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 18: ...Instructions for use 18 487 18 39 01 300 500 750 GB ...

Page 26: ...General installation 487 18 39 01 300 500 750 GB 26 ...

Page 38: ...Installation electric steam and gas heating 487 18 39 01 300 500 750 GB 38 ...

Page 46: ...Installation electric steam and gas heating 487 18 39 01 300 500 750 GB 44 2 ...