29

2

5

3

6

9

7

4

1

1

3

4

2

Installation

37

6598

A

B

6572

38

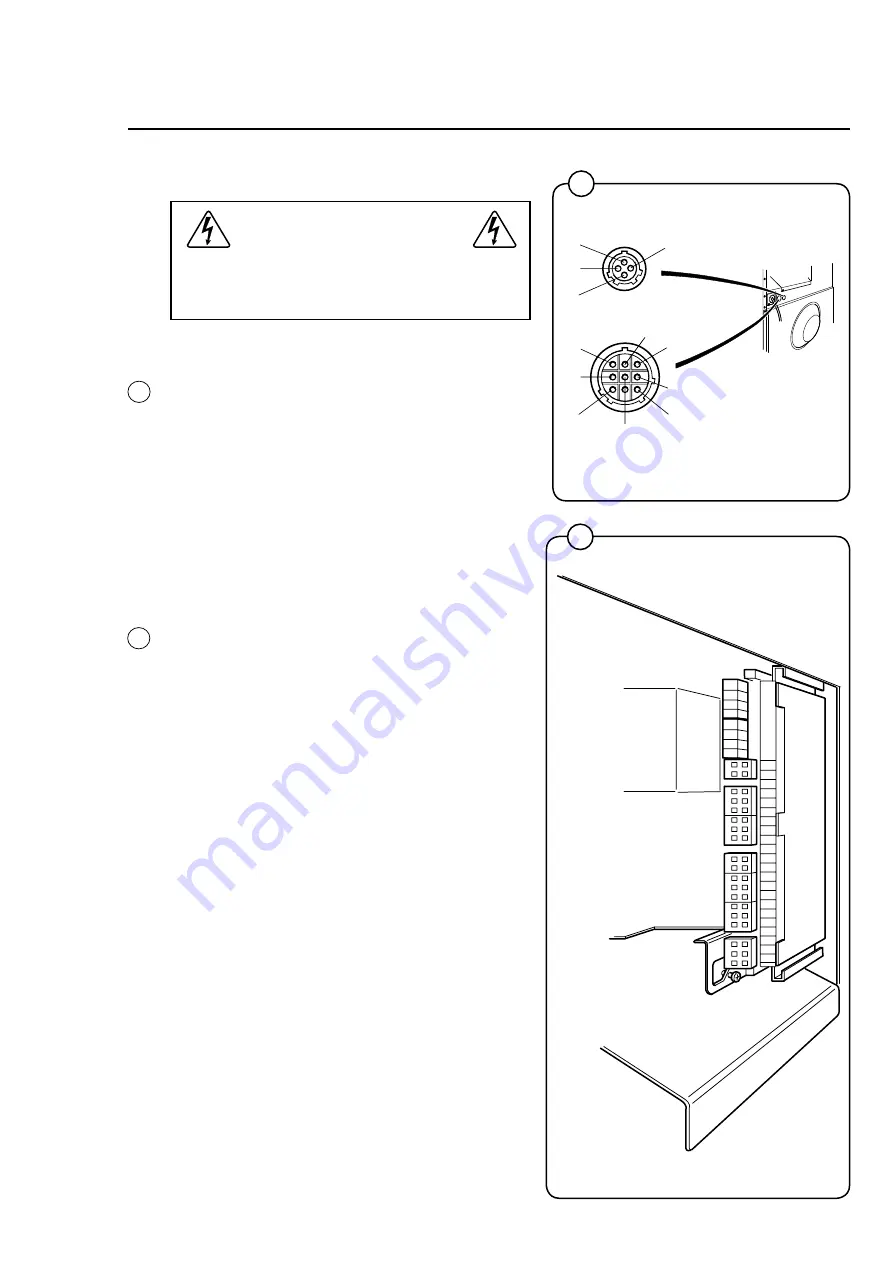

Connection of external liquid supplies

The external dosing equipment power

supply must never be connected to the

machine’s incoming terminal block.

Machines fitted with connectors

• Connect the pump equipment to connections

A and B on the washing machine.

Connect the signal cable to B and the power

supply to A.

Machines without connectors

• Connect the external pump equipment for

liquid washing detergent to the I/O board,

which is located to the right of the incoming

power supply.

The I/O card has edge connectors for connec-

ting external pumps.

• Edge connectors on the I/O board can be

loosened for connecting cables.

37

38

1 = N

2 = L

4 = Ground

1 = N

2 = Program run

3 = Signal 1

4 = Signal 2

5 = Signal 3

6 = Signal 4

7 = Signal 5

11 = N

18 = Program run

12 = Signal 1

13 = Signal 2

14 = Signal 3

15 = Signal 4

16 = Signal 5