16

Part 2 - USE AND MAINTENANCE INSTRUCTIONS

1 3

1 3

1 3

1 4

1 4

1 4

3

-

MAINTENANCE

Regular maintenance will ensure good performance and extend the working life of

the hood. Special attention should be taken to the grease filters and, for the filter

hoods only, to the charcoal filters.

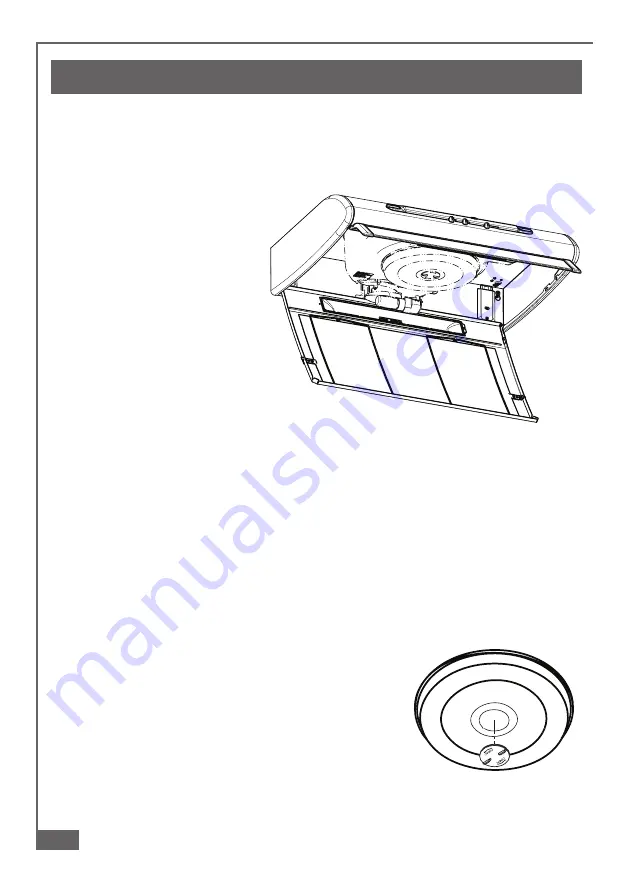

3.1 - Synthetic grease filters

1 - They cannot be washed and

should be replaced every two

months on average. If the filter

is equipped with chemical

indicators of saturation, replace

it when the visible red-coloured

dots show all over the surface.

2 - Replacement

Open the grid panel, remove the

steel-wire clips and replace the

grease filter

(fig. 13)

. Close the

grid panel.

3.2 - Metal grease filters

1 - Cleaning

These filters need to be washed with ordinary household detergent every 2 months

maximum. Thanks to their reduced dimensions, they can also be washed in the

dishwasher.

2 - Removing the filter

Open the grid panel, remove the steel wire clips and the grease filter

(fig. 13)

. Make

sure that the filter is dry before replacing it, close the grid panel.

WARNING : Respect replacement and maintenance schedules recommended

in order to avoid fire hazards caused by over-saturated filters.

3.3 - Charcoal filters

1 - How they work

Charcoal filters can absorb smells and odours until they

are saturated. They cannot be washed or recycled and

so they should be replaced at least every 4 months or

more frequently if the hood is heavily used.

2 - Replacement:

Open the grid panel, replace the charcoal filter by turning

the locking handle anti-clockwise for removing and

clockwise for replacing

(fig. 14)

. Close the grid panel.